Metal Storage Rack Upright Pillar Roll Forming Machine Enhancing Efficiency in Storage Solutions

In today's industrial landscape, efficient storage solutions are paramount for optimizing space and improving workflow. One of the critical components of metal storage racks is the upright pillar, which plays a vital role in supporting the structure and ensuring durability. To meet the increasing demand for high-quality metal storage racks, the metal storage rack upright pillar roll forming machine has emerged as an essential tool for manufacturers. This innovative machine not only streamlines the production process but also enhances the overall quality and consistency of the final product.

Understanding Roll Forming Technology

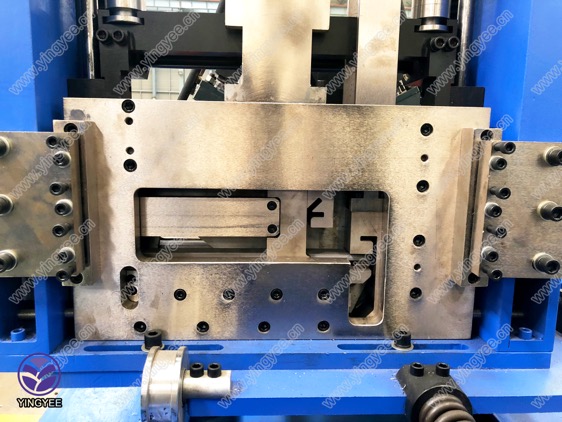

Roll forming is a continuous bending process in which a long strip of metal is gradually shaped into the desired cross-section. By passing the metal sheet through a series of rollers, it is progressively shaped into upright pillars tailored for storage racks. This technique offers numerous advantages, including high production efficiency, minimal material waste, and the ability to create complex profiles that can accommodate various design specifications.

The roll forming process begins with the selection of high-quality raw materials, typically cold-rolled or galvanized steel, which are crucial for ensuring the strength and resilience of the storage racks. The metal sheets are fed into the roll forming machine, where they traverse through multiple sets of rollers. Each set of rollers performs a specific function, gradually bending the sheet into the required shape of the upright pillar.

Advantages of Using a Metal Storage Rack Upright Pillar Roll Forming Machine

1. High Efficiency One of the most significant advantages of using a roll forming machine is the efficiency it brings to production. The continuous process allows for high-speed manufacturing, which can significantly reduce production lead times. This efficiency is crucial for businesses that need to meet tight deadlines and increasing customer demands.

2. Customization Flexibility The roll forming process is inherently flexible. Manufacturers can easily change the design of the upright pillar by adjusting the roller configurations. This capability allows for the production of customized racks that cater to specific storage needs, whether for warehouses, retail environments, or industrial applications.

3. Consistency and Quality The precision engineering involved in roll forming ensures that each upright pillar produced is consistent in shape and dimension. This uniformity is vital for ensuring that the storage racks can be assembled easily and function properly. Additionally, the process minimizes the risk of defects, leading to higher product quality overall.

4. Material Savings The design of the roll forming process allows for the efficient use of materials, reducing waste and lowering production costs. By optimizing the use of raw materials, manufacturers can not only save money but also contribute to more sustainable production practices.

5. Versatility Roll forming machines can be equipped with various tools and attachments to produce different types of profiles. This versatility means that manufacturers can expand their product offerings without investing in multiple machines, allowing for greater market adaptability.

Future Developments in Roll Forming Machines

As technology continues to advance, the future of metal storage rack upright pillar roll forming machines looks promising. Innovations such as automation, integrating artificial intelligence for quality control, and improved energy efficiency are expected to play significant roles in the development of these machines. Automated systems can increase production speeds and reduce human error, while advancements in machine design can further enhance their capabilities.

Conclusion

The metal storage rack upright pillar roll forming machine is a vital piece of equipment for manufacturers striving to produce high-quality, efficient storage solutions. By harnessing the advantages of roll forming technology, businesses can not only improve their production processes but also meet the dynamic needs of their clients. As the industry evolves, continued innovation in roll forming technology will likely pave the way for even more efficient and adaptable storage solutions, solidifying its place as a cornerstone of modern manufacturing.