Investing in a metal standing seam folding machine is a pivotal decision for businesses in the sheet metal and roofing industries. These machines promise a substantial boost in productivity and quality, revolutionizing how metal seams are created and manipulated. This article delves into the sophisticated mechanics, professional advantages, and trust factors associated with these machines, promising a comprehensive understanding essential for buyers and industry experts.

Foremost, the metal standing seam folding machine is engineered with precision to handle a myriad of metal types and thicknesses. The machine’s defining feature is its automated folding capability, offering unparalleled efficiency. By using computer-controlled settings, the machine guarantees consistently accurate folds, eliminating manual errors and reducing material waste. Operators can adjust parameters such as fold angle and seam width, ensuring versatility to cater to diverse project requirements, from commercial buildings to intricate architectural designs.

Experience utilizing these machines across varied projects highlights their transformative impact. A roofing specialist with over a decade of experience, Michael Andrews, shares, Before integrating the folding machine into our processes, we struggled with inconsistency and time delays. Now, not only have we halved our production time, but the precision of our seams has also significantly improved, which is critical for weather resistance and aesthetic appeal. This testimonial underscores how such machines enhance operational efficiency while elevating workmanship standards, fostering trust among clients reliant on durable, visually pleasing results.

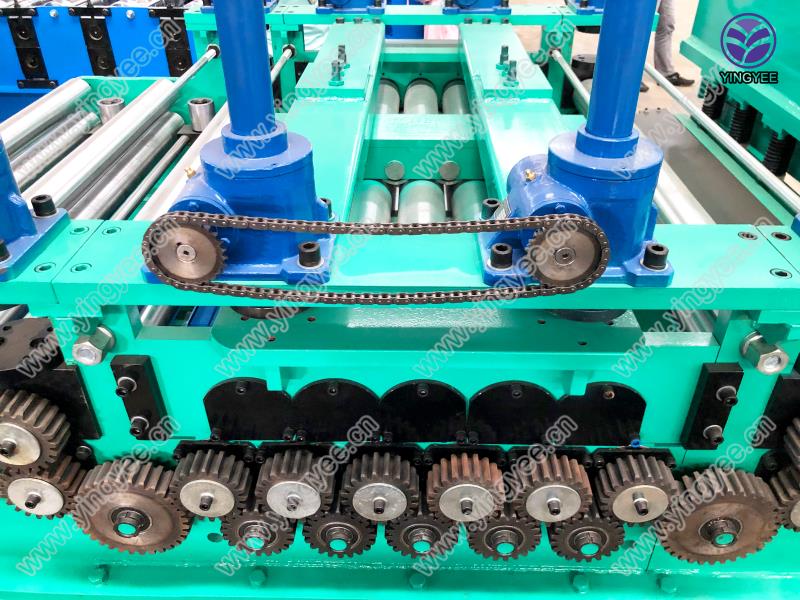

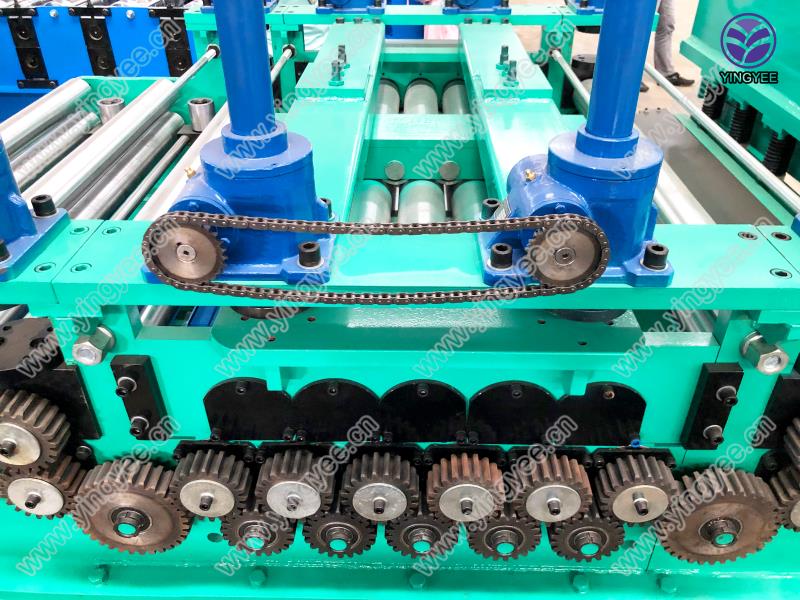

On the technical forefront, selecting the right metal standing seam folding machine necessitates an understanding of its core components and capabilities. Machines equipped with advanced servo-motor technology deliver high torque and precise control, ensuring seamless operation even with heavier metals. Moreover, the adoption of intuitive user interfaces with touch-screen controls simplifies complex tasks, allowing technicians to focus on strategic decisions rather than operational hurdles. This synergy between machinery and expertise propels businesses towards achieving superior output and customer satisfaction.

metal standing seam folding machine

From an industry standpoint, the authority of manufacturers plays a crucial role. Leading brands invest heavily in research and development, ensuring that their machines are at the forefront of innovation. By collaborating with metalworking associations and certification bodies, these manufacturers establish credibility, reassuring potential buyers about the reliability and performance of their products. Moreover, comprehensive training programs offered by manufacturers equip users with essential skills and knowledge, further cementing the machine's role as a valuable asset in any metalworking operation.

Trustworthiness, meanwhile, is enhanced by robust after-sales support. Manufacturers who provide extensive warranties and responsive customer service ensure peace of mind for buyers. Access to genuine spare parts and technical support are critical factors that influence long-term satisfaction and loyalty. As businesses navigate complexities in operations, knowing that expert assistance is readily available reinforces confidence in making such a substantial capital investment.

In conclusion, metal standing seam folding machines represent a vital advancement in metalworking technologies, marrying expertise with experience to deliver authoritative and reliable solutions. By emphasizing precision, dependability, and expert support, these machines not only meet but exceed industry expectations, cementing their role as indispensable tools for professionals committed to excellence in their craft.