Understanding the Metal Standing Seam Folding Machine

The metal standing seam folding machine is an essential tool in the roofing and architectural cladding industries, designed to enhance efficiency and precision in the manufacturing of metal roofing systems. These machines are tailored to create standing seam roofs, which are characterized by vertical seams that interlock to provide superior weather resistance, aesthetics, and durability.

What is a Standing Seam Roof?

A standing seam roof consists of vertical panels that are secured to the building's substrate with raised seams. These seams are not only functional but also add a sleek, modern appearance to structures. The design allows for thermal expansion and contraction of the metal, which significantly reduces the risk of leaks and enhances the roof's lifespan. The standing seam roofing system is increasingly popular in both commercial and residential sectors due to its longevity, energy efficiency, and minimal maintenance requirements.

The Functionality of the Folding Machine

The metal standing seam folding machine automates the process of bending and folding metal sheets to create the necessary profiles for standing seam roofs. These machines can produce various seam heights and widths, accommodating different design preferences and structural requirements.

One of the primary advantages of using a folding machine is the precision it offers. Manual processes can lead to inconsistencies and errors, particularly when handling large sheets of metal. A folding machine, equipped with advanced technology and digital controls, ensures accurate dimensions and uniformity across all panels. This precision translates to a better fit during installation, contributing to the overall quality and longevity of the roof.

Key Features of the Metal Standing Seam Folding Machine

1. Adjustable Settings Most folding machines allow for adjustable bending angles and profiles, making it easier to customize panels for specific projects. This versatility is crucial for contractors who face diverse building designs.

2. Automation and Efficiency Modern metal folding machines often incorporate pneumatic or hydraulic mechanisms that facilitate easy operation with reduced manual effort. This automation speeds up the workflow, enabling manufacturers to meet tight deadlines.

3. Durability and Maintenance Built to handle various gauges and types of metal, including aluminum and steel, these machines are constructed from robust materials that withstand rigorous use. Regular maintenance and proper care can ensure a long service life.

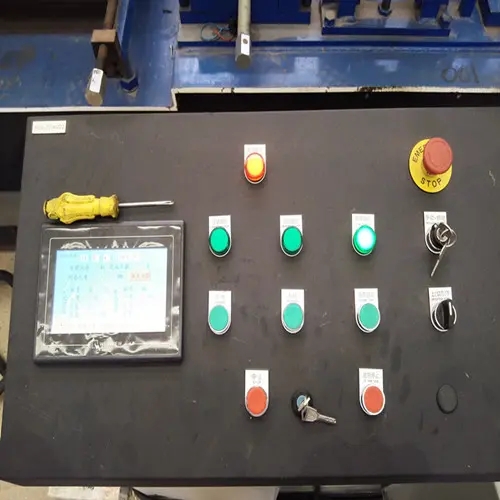

4. Safety Features Safety is paramount in industrial settings. Many folding machines are equipped with features such as emergency stops, safety guards, and user-friendly controls to minimize accidents and injuries during operation.

Applications in Construction

The metal standing seam folding machine plays a crucial role in various construction applications. It is instrumental in fabricating metal roofing panels that can be installed on commercial buildings, residential homes, and industrial facilities. Additionally, beyond roofing, these machines are also used for producing metal walls, fascia, and other architectural elements.

As sustainability becomes a priority in construction, standing seam roofs offer energy-efficient solutions. The raised seams allow for the installation of insulation underneath, reducing heating and cooling costs. Moreover, metal roofing materials are often made from recycled content and are themselves recyclable, aligning with green building initiatives.

The Future of Metal Folding Technology

As technology advances, the capabilities of metal standing seam folding machines continue to evolve. Features like integrated design software, real-time monitoring systems, and connectivity to cloud services are becoming standard. This integration allows for seamless data exchange between design and manufacturing, further streamlining the production process.

Moreover, the rise of smart manufacturing and Industry 4.0 means that these machines can become fully automated and interconnected within larger manufacturing systems. This trend will likely enhance productivity, reduce waste, and create a more sustainable production environment.

Conclusion

In conclusion, the metal standing seam folding machine represents a vital advancement in the roofing and architectural sector. Its precision, efficiency, and versatility make it an indispensable tool for manufacturers and contractors alike. As the industry adapts to new technological advancements, these machines will continue to play a crucial role in the creation of durable, energy-efficient, and aesthetically pleasing metal roofs. The future looks bright for standing seam technology, promising enhanced performance and sustainability in building design and construction.