The Importance of Metal Standing Seam Folding Machines in Modern Construction

In recent years, the construction industry has increasingly embraced innovative technologies aimed at enhancing efficiency, reducing waste, and improving the quality of finished products. One of the noteworthy advancements in this domain is the metal standing seam folding machine. This equipment plays a crucial role in the production of roofing and cladding solutions, providing seamless, durable, and watertight installations that are vital for modern architecture.

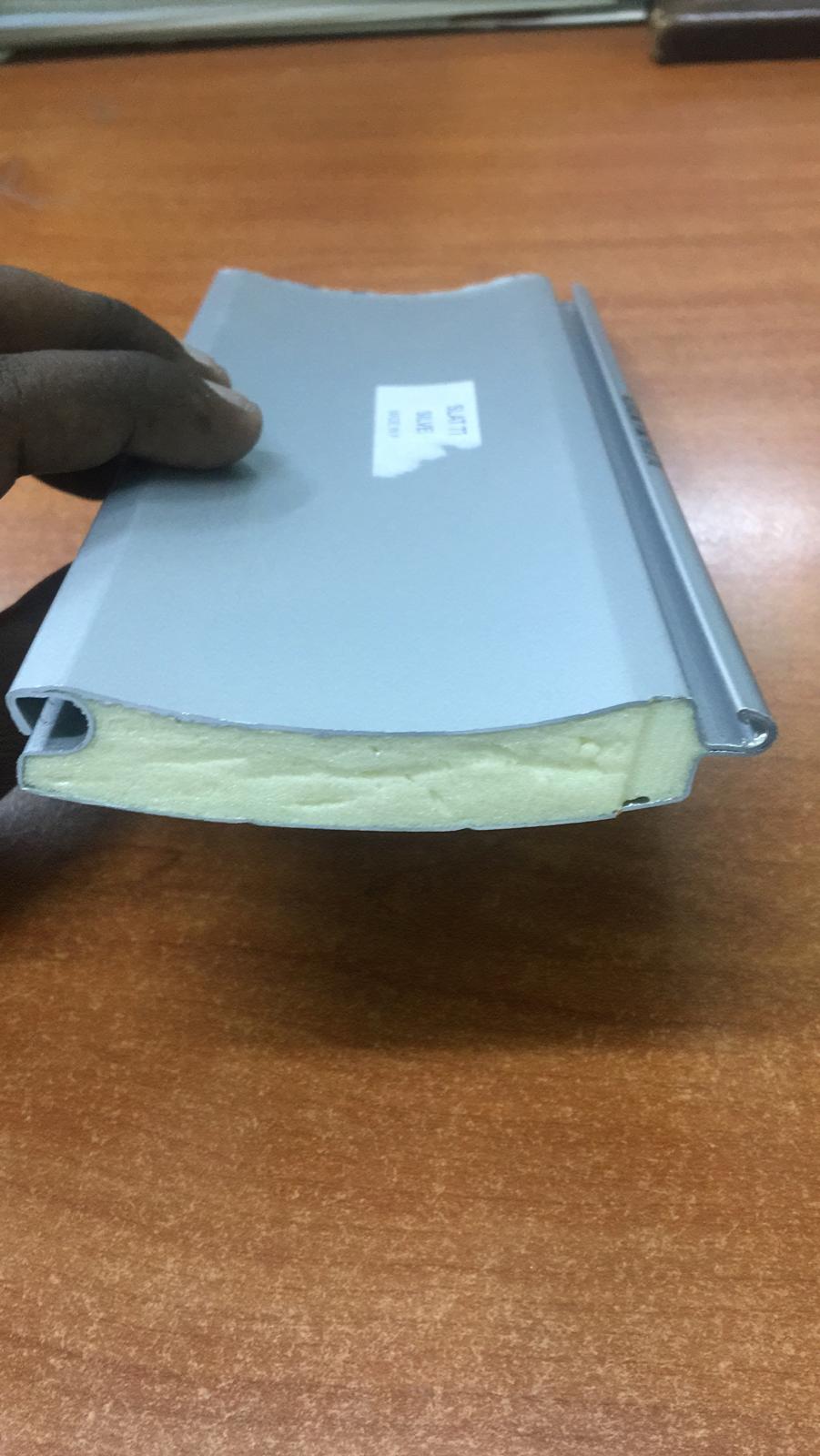

A metal standing seam roof consists of long panels that run vertically from the peak of the roof to the eaves. They are characterized by raised seams that interlock, providing a strong barrier against weather elements. The installation of such roofs requires precision, and this is where metal standing seam folding machines come into play. These machines automate the folding process of metal sheets, ensuring consistent angles and dimensions that are vital for the functionality and aesthetics of the roofing system.

How Does a Metal Standing Seam Folding Machine Work?

The operation of a metal standing seam folding machine is relatively straightforward yet highly effective. The machine is designed to accommodate metal sheets, typically composed of aluminum, steel, or copper. Once a sheet is loaded, the machine guides it through a series of rollers that fold the edges at precise angles. This process not only creates the standing seams but also eliminates the need for additional fastening methods, which can be time-consuming and labor-intensive.

The advanced models of these machines also incorporate digital controls, allowing operators to input specific parameters for different projects. This feature enhances accuracy and minimizes human error, leading to higher quality outputs. Furthermore, many machines come equipped with programmable settings, enabling manufacturers to switch between different profiles quickly, thus accommodating a variety of designs and styles.

Benefits of Using Metal Standing Seam Folding Machines

1. Increased Efficiency One of the primary advantages of using a metal standing seam folding machine is the speed at which it can operate. Traditional manual methods involve considerable time and effort, while machines can produce high-quality seams in a fraction of the time. This efficiency leads to shorter project timelines and reduced labor costs.

2. Enhanced Quality Consistency is key in construction, and a metal standing seam folding machine guarantees uniform folds, resulting in better-fitting panels. The precision offered by these machines reduces the chances of leaks and structural failures, as each seam is crafted to exact specifications.

3. Versatility These machines can handle a variety of metal materials and can be configured to produce different seam profiles. This versatility makes them an essential tool for contractors who work on diverse projects, from residential buildings to commercial structures.

4. Reduced Waste By ensuring precise cuts and folds, metal standing seam folding machines significantly minimize material waste. This not only helps in cost savings but also contributes to more sustainable construction practices, aligning with the industry's move towards environmentally friendly solutions.

5. Ease of Use Modern machines come with intuitive interfaces and automated features that simplify operation. This allows even less experienced workers to achieve professional results, effectively expanding the labor pool capable of handling such tasks.

Conclusion

In an era defined by rapid technological advancement and the need for sustainable construction practices, the metal standing seam folding machine stands out as a pivotal tool in the building industry. Its ability to enhance efficiency, improve quality, and reduce waste makes it indispensable for manufacturers and contractors focused on delivering superior roofing and cladding solutions. As the construction landscape continues to evolve, the integration of such innovative machinery will undoubtedly play a significant role in shaping the future of architectural design and building practices. Embracing these tools not only aligns with current industry trends but also sets the stage for smarter, more efficient construction methods in the years to come.