Understanding the Metal Standing Seam Folding Machine

In the world of metal roofing and cladding, efficiency and precision play crucial roles. The metal standing seam folding machine is an essential piece of equipment that not only enhances productivity but also ensures high-quality finishes in metal sheet applications. This machine is specifically designed to fold metal sheets to create standing seams, which are vital for roofing systems and various architectural applications.

Structure and Functionality

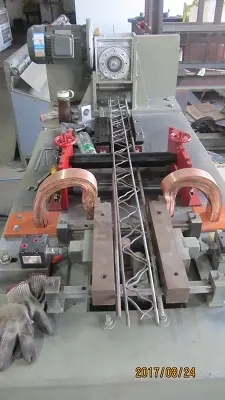

A metal standing seam folding machine typically consists of several key components the feed table, folding arms, and a control panel. The process begins when metal sheets are fed into the machine, where they are accurately positioned. The folding arms, operated either manually or via automated controls, bend the edges of the metal sheets to create seams.

The ability to produce consistent and precise folds is crucial in ensuring that the standing seams align perfectly during installation

. This precision is necessary for both aesthetic appeal and functional performance, as standing seams provide excellent water resistance and durability.Advantages of Using a Metal Standing Seam Folding Machine

One of the primary advantages of using a metal standing seam folding machine is the enhanced efficiency it provides. Traditional methods of folding metal seams can be labor-intensive and time-consuming. With a dedicated folding machine, the process is streamlined, allowing operators to achieve the desired folds in a fraction of the time. This efficiency not only speeds up production but also minimizes labor costs.

Moreover, metal folding machines are designed to accommodate various types of metal, including aluminum, zinc, and steel. This versatility allows manufacturers to cater to a broad range of customer requirements and project specifications. By being able to work with different materials, businesses can expand their product offerings and tap into new markets.

Precision and Quality

Precision is another significant benefit that metal standing seam folding machines bring to the table. The ability to create uniform and accurate folds reduces the likelihood of installation errors, ensuring that the seams fit together snugly and securely. This precision is particularly important in environments with harsh weather conditions, where the integrity of the roofing system is paramount.

Additionally, the quality of the finished product is enhanced when using specialized folding machines. A well-folded seam not only looks better but also contributes to the overall durability of the roofing system. Thanks to the machine’s ability to apply consistent pressure and angles during the folding process, each seam achieves a high level of quality that is often difficult to replicate with manual methods.

Conclusion

In conclusion, the metal standing seam folding machine is an invaluable tool in the metalworking and roofing industries. Its ability to improve efficiency, ensure precision, and enhance the overall quality of seams makes it a preferred choice among manufacturers. As technology continues to evolve, the capabilities of these machines are likely to expand, further supporting the growing demand for reliable and aesthetically pleasing metal roofing solutions. For anyone involved in metal fabrication or roofing, investing in a standing seam folding machine can provide significant returns in terms of productivity, quality, and customer satisfaction.