Understanding the Metal Sound Barrier Cold Bending Machine

The advancement of manufacturing technology has introduced numerous innovations in various sectors, particularly in the field of construction and infrastructure. One such innovation that has garnered attention is the metal sound barrier cold bending machine. This specialized piece of equipment plays a vital role in the production of sound barriers, which are increasingly essential in urban environments where noise pollution is a growing concern.

What is a Metal Sound Barrier?

Sound barriers, also known as noise barriers, are structures designed to obstruct or deflect sound waves, particularly those produced by traffic and industrial activities. They are typically made from materials such as concrete, wood, and metal. Among these, metal sound barriers have gained popularity due to their durability, aesthetic appeal, and effectiveness in noise reduction.

The Role of Cold Bending Machines

Cold bending machines are essential in the manufacturing of metal sound barriers. Unlike traditional bending methods that may involve heat, cold bending uses the mechanical properties of metals at room temperature to achieve desired shapes without compromising their integrity. This process enhances the structural strength of the metal, making it an ideal choice for sound barriers that must withstand environmental pressures, including wind and impact.

How Does the Cold Bending Process Work?

The cold bending process involves several key steps. First, metal sheets or sections are fed into the bending machine. The machine is equipped with precise control features that ensure accuracy in angles and dimensions. As the metal is bent, it retains its original properties, which avoids issues like warping or thinning that can occur with heated processes.

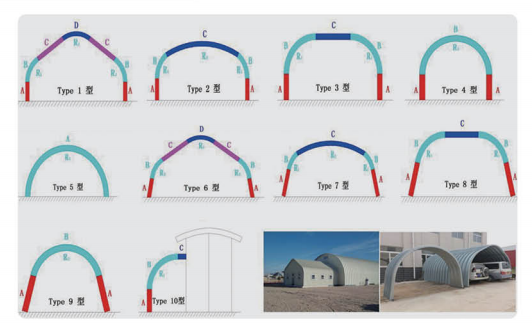

Typically, the machine employs hydraulic or mechanical mechanisms to exert force on the metal. By adjusting the machine's settings, operators can create different shapes suited for various sound barrier designs, such as curved or straight profiles. This flexibility allows manufacturers to cater to specific project requirements while optimizing the use of materials.

Advantages of Metal Sound Barrier Cold Bending Machines

1. Durability Metal sound barriers created using cold bending techniques are inherently more robust and resistant to weathering, making them a long-term solution for noise control.

2. Cost-Efficiency The efficiency of the cold bending process reduces material wastage and lowers production costs compared to other bending methods.

3. Speed of Production Cold bending machines can process materials quickly, significantly speeding up the manufacturing timeline for sound barriers.

4. Design Versatility The ability to create complex shapes allows for greater design flexibility, enabling architects and engineers to integrate sound barriers seamlessly into their projects.

5. Reduced Environmental Impact As cold bending does not require heat, the energy consumption is lower, contributing to a smaller carbon footprint during production.

Applications of Metal Sound Barriers

The applications for metal sound barriers are extensive. They are prominently used along highways, railways, and within industrial areas to mitigate noise pollution. Additionally, urban developers utilize them in residential areas to create sound-buffer zones, thus enhancing the quality of life for residents.

In conclusion, the metal sound barrier cold bending machine represents a critical technological advancement in sound mitigation strategies. Its ability to produce high-quality, durable, and aesthetically appealing sound barriers facilitates the continuous effort to combat noise pollution in growing urban environments. As cities expand and populations rise, the demand for effective noise control solutions will likely lead to further innovation and improvements in cold bending technology, ensuring that our urban landscape remains both functional and pleasant.