Understanding Metal Slitting Lines The Key to Precision Metal Processing

In the realm of metal processing, the efficiency and precision of manufacturing tools greatly influence the quality of the final product. Among the various machinery employed in the industry, metal slitting lines have gained prominence for their ability to produce narrow strips of metal with exceptional accuracy. This article sheds light on the intricacies of metal slitting lines, their operational mechanisms, and their importance in various applications.

What is a Metal Slitting Line?

A metal slitting line is a specialized assembly of machinery designed to cut large rolls of metal, or coils, into narrower strips. The slitting process involves the use of sharp blades that slice through the metal as it is fed through the line. These lines are particularly useful for processing materials like stainless steel, aluminum, and carbon steel, which are widely used in the manufacturing sector.

Components of a Metal Slitting Line

A typical metal slitting line consists of several critical components, each playing a vital role in the slitting process

1. Uncoiler The process begins with the uncoiler, which holds and unwinds the large master coil of metal. This component is essential for feeding the material smoothly into the slitting line without causing any damage.

2. Leveling System After the material is unwound, it often requires leveling to ensure uniform thickness and flatness. The leveling system employs rollers that remove internal stresses in the metal and prepare it for accurate slitting.

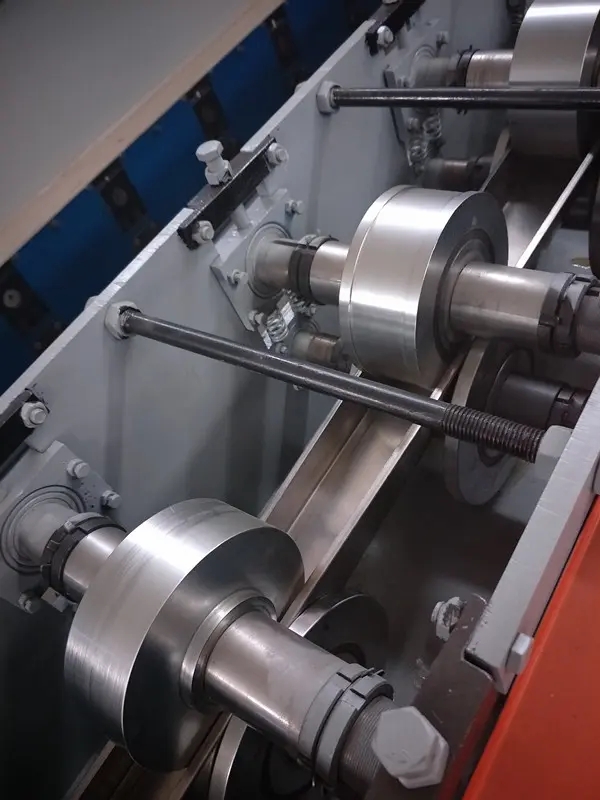

3. Slitting Machine This is where the cutting action occurs. The slitting machine features rotating circular blades that slice through the metal strip longitudinally. The precision of these blades determines the accuracy and quality of the slits produced.

4. Scrap Winder As the metal is slitted, there will often be a scrap edge generated. The scrap winder collects this waste material, ensuring that the operation remains clean and efficient.

5. Recoiler Finally, after the slitting process, the narrower metal strips are wound onto a recoiler. This component organizes the final products for storage or further processing.

The Slitting Process

The slitting process is highly automated and typically involves several stages. The metal coil unwinds and passes through the leveler, which flattens it. The leveled metal then enters the slitting machine, where circular blades cut it into the desired widths. Each strip, once cut, is accurately measured and wound onto the recoiler. This seamless transition from one step to the next is what makes metal slitting lines incredibly efficient.

Applications of Metal Slitting Lines

Metal slitting lines are employed across various industries, including automotive, aerospace, construction, and electronics. For instance, in the automotive industry, slitted metal strips are used for manufacturing components such as brackets, panels, and reinforcement parts. In electronics, these strips are essential for producing connectors and other intricate parts. The versatility of metal slitting lines allows manufacturers to meet diverse demands while maintaining high standards of precision.

Advantages of Metal Slitting Lines

One of the primary advantages of metal slitting lines is the ability to achieve tight tolerances, ensuring that each strip meets specific dimensional requirements. This is crucial for industries where even the slightest deviation can compromise product quality. Additionally, modern slitting lines are equipped with advanced controls and automation, which enhance speed and reduce labor costs.

Furthermore, metal slitting lines contribute to efficient material usage. By producing narrow strips from larger coils, manufacturers can minimize waste and lower production costs. This efficiency not only benefits companies economically but also supports sustainability efforts by reducing scrap material.

Conclusion

In summary, metal slitting lines play a pivotal role in the metal processing industry by transforming large coils into precisely defined strips. Their intricate design and operational efficiency make them indispensable in various applications, enabling manufacturers to produce high-quality components while optimizing resource use. As technology progresses, the capabilities of metal slitting lines will continue to evolve, further enhancing their significance in modern manufacturing.