Metal Roofing Sheet Making Machine An Innovative Solution for Modern Construction

The construction industry has always been at the forefront of innovation, with new technologies continuously emerging to enhance efficiency, sustainability, and quality. One such innovation is the metal roofing sheet making machine, a specialized piece of equipment designed to produce high-quality metal roofing sheets for various applications. As the demand for durable and aesthetically appealing roofing solutions increases, these machines have become essential in modern manufacturing processes.

Metal roofing sheets offer numerous advantages over traditional materials. They are lightweight, durable, and resistant to harsh environmental conditions, making them an ideal choice for both residential and commercial buildings. Moreover, metal roofs are known for their longevity, often lasting twice as long as conventional roofing materials. This durability not only reduces the need for frequent replacements but also contributes to lower lifecycle costs, making metal roofing an economically attractive option.

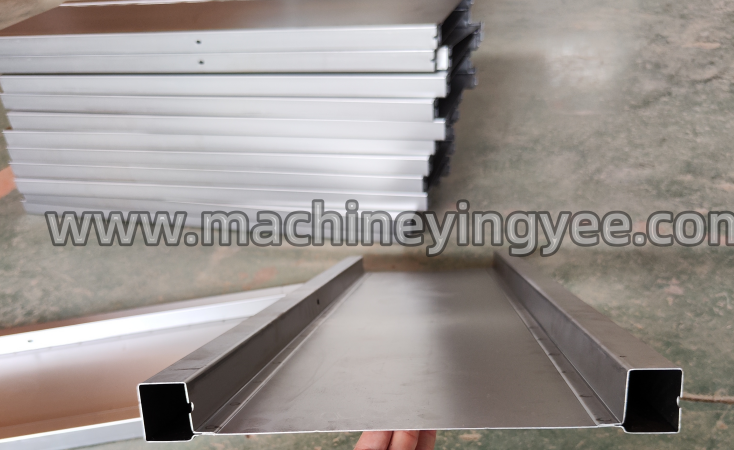

The metal roofing sheet making machine operates through a continuous production process. It typically involves several stages, starting with the feeding of raw metal coils into the machine. The coils are gradually shaped and formed into sheets using a series of rollers and dies. The precision engineering of these machines ensures that the final product meets exact specifications, including thickness, width, and profile design. Advanced models even incorporate automated features, such as computerized controls, which enhance accuracy and reduce labor costs.

One of the key benefits of utilizing a metal roofing sheet making machine is the flexibility it offers in terms of production. Manufacturers can easily tailor the machine settings to produce various styles of roofing sheets, from standing seam to corrugated patterns. This adaptability allows businesses to respond quickly to market trends and customer preferences, ensuring they remain competitive in a rapidly evolving industry.

Sustainability is another crucial aspect driving the popularity of metal roofing sheet making machines. The use of recyclable materials in metal roofing production aligns with global efforts towards environmental conservation. Additionally, metal roofs are known for their energy-efficient properties, reflecting solar heat and contributing to lower energy consumption in buildings. This eco-friendly approach is increasingly appealing to environmentally-conscious consumers and builders alike.

In conclusion, the metal roofing sheet making machine represents a significant advancement in the construction sector. Its ability to produce high-quality, durable roofing materials not only supports builders and manufacturers but also meets the evolving needs of consumers. With its combination of efficiency, flexibility, and sustainability, this machine is poised to play a crucial role in shaping the future of roofing materials and construction practices. As the demand for metal roofing continues to grow, investing in such machinery will undoubtedly yield long-term benefits for businesses in the industry.