Metal Roof Forming Machine Revolutionizing the Roofing Industry

In recent years, the roofing industry has undergone significant advancements, and one of the pivotal innovations is the metal roof forming machine. These machines have transformed the way metal roofs are produced, making the process faster, more efficient, and cost-effective. This article explores the functions, benefits, and technological advancements of metal roof forming machines, along with their impact on the construction sector.

What is a Metal Roof Forming Machine?

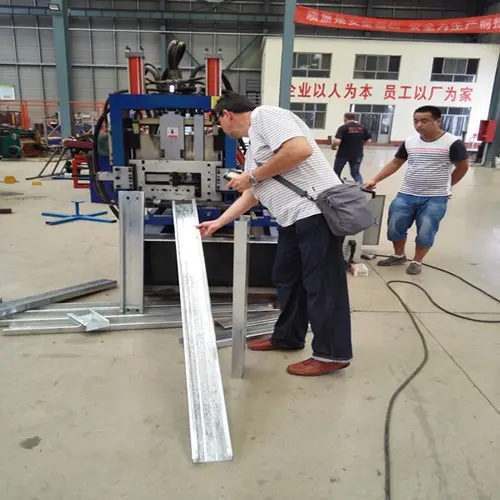

A metal roof forming machine is specialized equipment designed to produce roofing panels from metal sheets. These machines operate by feeding metal coils through a series of rollers that continuously shape and cut the material into the desired profile. The result is high-quality metal roofing panels that can be directly installed on buildings, offering a durable and appealing alternative to traditional roofing materials.

How Does It Work?

The metal roof forming process begins with loading a coil of metal, typically steel or aluminum, into the machine. The coil is unrolled and fed into a series of rollers that progressively shape the metal into the desired profile. Depending on the machine's configuration, it can produce various styles, including standing seam, corrugated panels, and tile patterns. Once the panels are formed, they can be cut to length according to project specifications. Some machines also integrate additional features, such as embossing, to enhance the aesthetic appeal of the resulting panels.

Advantages of Using Metal Roof Forming Machines

1. Efficiency and Speed Traditional roofing methods often involve significant labor and time. Metal roof forming machines automate much of this process, drastically reducing production times. A skilled operator can quickly produce large quantities of roofing panels, making it ideal for large-scale projects.

2. Cost-Effectiveness By streamlining the production process, these machines help reduce labor costs and material waste. The precision of the machines ensures that panels fit perfectly, minimizing errors during installation.

3. Durability and Strength Metal roofs are known for their longevity and resistance to harsh weather conditions. The use of high-quality materials and advanced forming techniques enhances the strength of the roofing panels, making them suitable for various climates.

4. Versatility Metal roof forming machines can produce a wide range of profiles and designs, allowing contractors to cater to diverse architectural styles. Whether a building requires a sleek modern look or a traditional aesthetic, these machines can adapt to meet specific needs.

5. Eco-Friendliness Metal roofing is often made from recycled materials and is fully recyclable at the end of its life cycle. The efficiency of metal roof forming machines also contributes to a reduction in waste, making them an environmentally friendly option for construction.

Technological Advancements

Recent technological advancements have further enhanced the capabilities of metal roof forming machines. The introduction of computerized controls allows for precise adjustments in real time, ensuring that production meets exact specifications. Additionally, automation and robotics are increasingly being integrated into these machines, which not only improve efficiency but also reduce the risk of human error.

Moreover, innovations in materials science have led to the development of coatings that enhance the performance of metal roofs. These coatings increase resistance to corrosion and UV exposure, further extending the lifespan of the roofing panels.

Conclusion

In conclusion, metal roof forming machines have revolutionized the roofing industry by providing a fast, efficient, and cost-effective solution for producing high-quality metal roofing panels. With their ability to create various profiles and designs, these machines empower contractors to meet the distinct needs of their clients while maintaining a focus on sustainability. As technology continues to evolve, the potential for further enhancements in metal roofing production becomes increasingly promising, positioning metal roofs as a leading choice in modern construction. Whether for residential, commercial, or industrial applications, the metal roof forming machine is undeniably a critical tool in shaping the future of roofing.