Metal Plate Straightening and Leveling Machines An Essential Tool for Precision Engineering

In the realm of metal processing, the shape and flatness of materials are crucial for ensuring the quality and performance of finished products

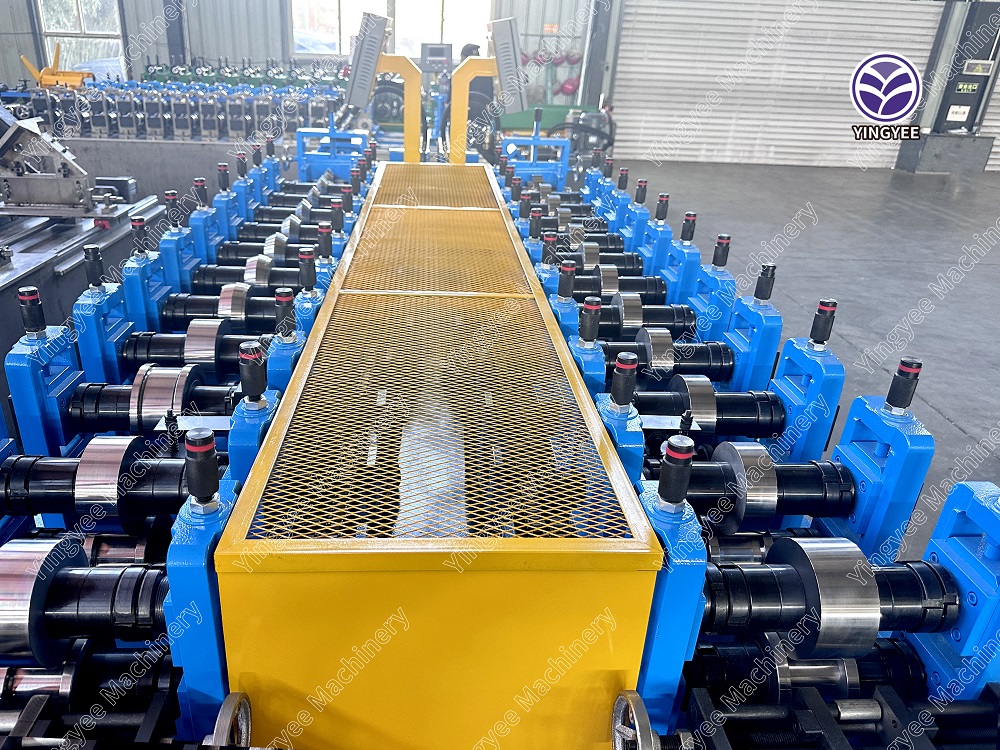

. Metal plate straightening and leveling machines play a pivotal role in enhancing the flatness of metal sheets and plates, making them a fundamental component in various industries, including construction, automotive, and aerospace.Metal plates often undergo various manufacturing processes that can lead to warping, bending, or distortion. This is especially true after processes such as welding, cutting, or rolling. When these plates are introduced to a straightening and leveling machine, they are subjected to controlled mechanical processes that help restore their original flat shape. The machines utilize a series of rollers or hydraulic systems to apply force strategically, allowing the material to be reshaped without compromising its structural integrity.

The technology behind these machines has evolved significantly over the years. Modern metal plate straightening and leveling machines are equipped with advanced features such as digital controls, automated feeding systems, and real-time monitoring capabilities. This not only enhances precision but also improves efficiency, reducing the time required for processing each plate. Operators can input specific parameters for desired flatness and thickness, ensuring that the final product meets stringent industry standards.

One of the key benefits of using metal plate straightening and leveling machines is the reduction in material waste. By effectively correcting deformities, these machines allow manufacturers to maximize the use of raw materials, thus lowering costs and minimizing environmental impact. Furthermore, the improved flatness of plates contributes to better welding and cutting processes, leading to higher quality assemblies and products.

In conclusion, metal plate straightening and leveling machines are indispensable tools in the manufacturing sector. They not only enhance the quality and applicability of metal products but also contribute to more sustainable production practices. As industries continue to demand higher precision and efficiency, the importance of these machines in achieving such goals cannot be overstated. Investing in advanced straightening and leveling technology is a step towards improving overall operational performance and product quality in metalworking processes.