The Evolution and Importance of Metal Forming Machines

In an era where manufacturing efficiency and precision are paramount, metal forming machines play a crucial role in modern production processes. These machines are designed to reshape metal materials into specific geometries, allowing for the creation of complex components used in various industries, including automotive, aerospace, electronics, and construction.

Understanding Metal Forming

Metal forming is a manufacturing process that involves the deformation of metal into desired shapes without removing material. This process can be categorized into two main types conventional forming and advanced forming techniques. Conventional methods include forging, rolling, extrusion, and stamping. Advanced techniques, on the other hand, encompass processes such as hydroforming, superplastic forming, and additive manufacturing. Each method has its own unique advantages and is suited for different applications, depending on the material type, desired shape, and production volume.

The Role of Metal Forming Machines

Metal forming machines are essential for executing the above processes effectively. These machines are engineered to exert precise force and control temperature to achieve the desired material properties and forms. Common types include

1. Presses These machines apply pressure to sheets of metal to cut, bend, or shape them. Mechanical and hydraulic presses are prevalent, each offering different advantages, such as speed and force control.

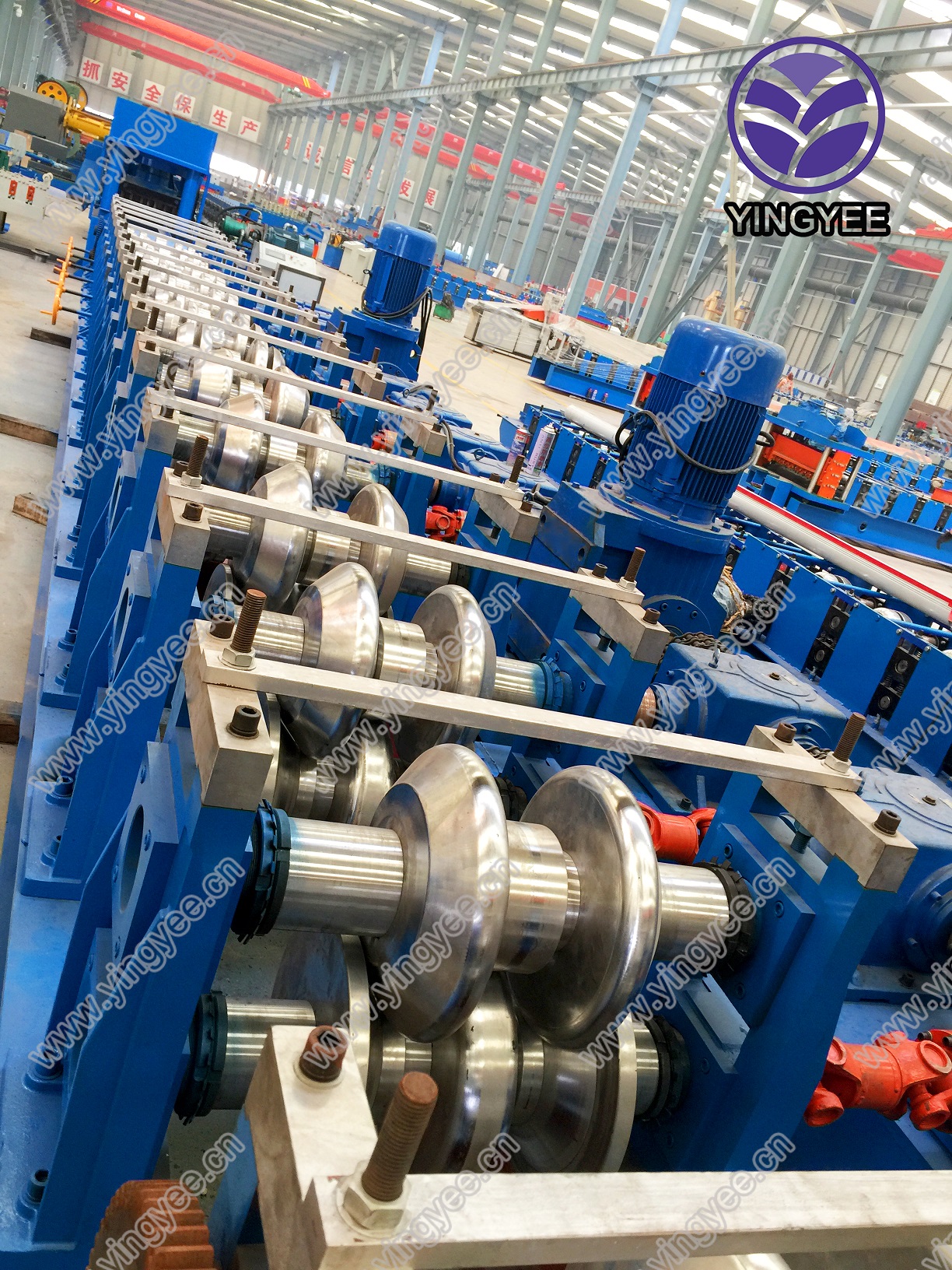

2. Roll Forming Machines Used primarily in the production of long sections with consistent cross-sections, roll forming machines continuously feed metal sheets through a series of rollers to achieve the final shape.

3. Forging Machines Forging is one of the oldest metal forming techniques. These machines can produce highly durable components through compressive forces, making them indispensable in industries requiring components that can withstand high stress.

4. Extrusion Machines Extrusion involves forcing metal through a die to create long shapes, such as tubes and bars. These machines are highly efficient in producing consistent cross-sectional profiles.

Recent Innovations

As technology advances, so do metal forming machines. The incorporation of robotics and automation has significantly enhanced production capabilities, leading to improved efficiency, reduced labor costs, and increased precision. Industry 4.0 is paving the way for smart manufacturing, where machines are interconnected and can communicate and adapt based on real-time data. This leads to optimized production processes, minimized waste, and higher product quality.

Furthermore, advancements in materials science have afforded manufacturers the ability to work with high-strength alloys and advanced materials like composites. Metal forming machines are now designed to handle these complex materials, enabling the production of lighter yet stronger components.

Environmental Considerations

The metal forming industry is increasingly focusing on sustainability. Modern machines are being designed to minimize energy consumption and material waste. Efforts to recycle scrap metal and utilize eco-friendly lubricants are on the rise, reflecting a commitment to reducing the environmental impact of manufacturing processes. Such initiatives not only benefit the planet but also enhance corporate responsibility and improve public perception.

Conclusion

The importance of metal forming machines cannot be overstated in today's manufacturing landscape. They enable the efficient production of high-quality components essential for various critical applications. As technology continues to evolve, these machines are becoming more sophisticated, incorporating automation, smarter design, and sustainable practices.

In a world that constantly demands innovation and improvement in manufacturing processes, investing in advanced metal forming machines is not just beneficial but necessary for businesses aiming to stay competitive in the global market. The future of manufacturing will undoubtedly continue to develop around these vital machines, driving progress in design and production efficiency across various sectors. As we look ahead, the role of metal forming machines will remain central to the advancement of industry, fostering growth and innovation in the ever-evolving landscape of technology and manufacturing.