Metal Forming Machines Revolutionizing Manufacturing Processes

Metal forming machines play a crucial role in the modern manufacturing landscape, serving as essential tools for shaping metal into desired forms. These machines employ various techniques to transform raw materials into finished products, contributing significantly to a wide array of industries, from automotive to aerospace and construction.

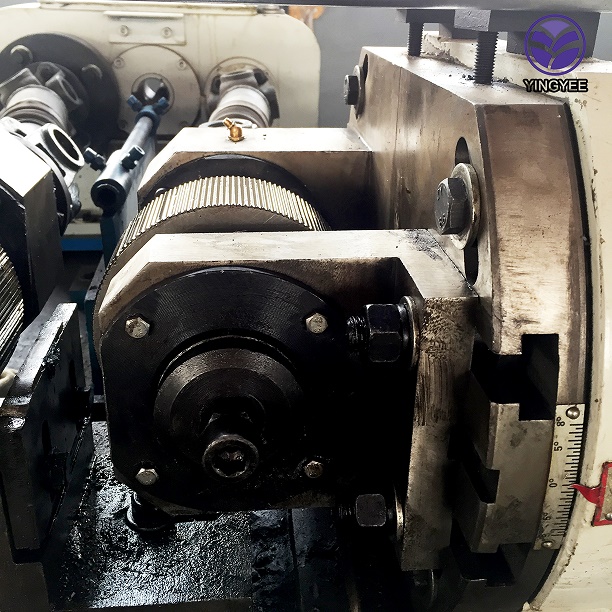

At the core of metal forming technology are several techniques, including stamping, bending, and forging. Stamping is a popular method that utilizes a die to cut or shape metal sheets into specific designs. This process is highly efficient, capable of producing large quantities of uniform parts in a short period. The automotive industry, for instance, relies heavily on stamping machines for producing components such as body panels and brackets.

Bending is another vital process in metal forming, where metal sheets or bars are shaped by applying force to create bends or curves. This technique offers versatility, allowing manufacturers to produce various shapes, from simple angles to complex curves. Bending machines, like press brakes, are commonly used in fabrication shops to create frames, brackets, and other structural components.

Forging, distinguished by its use of compressive forces, is a process that shapes metal by hammering or pressing it into a desired form. This method enhances the metal's strength by refining its grain structure, making forged components ideal for high-stress applications, such as in aerospace and heavy machinery. Forging machines, which include hammers and presses, are instrumental in producing durable and reliable parts that meet stringent quality standards.

In recent years, advancements in technology have led to the development of more sophisticated metal forming machines. The integration of computer numerical control (CNC) technology has enhanced precision and repeatability, reducing the likelihood of errors and increasing productivity. CNC metal forming machines can be programmed to execute complex designs with a level of accuracy that manual methods cannot achieve. This evolution not only improves the quality of the finished product but also streamlines the manufacturing process, allowing for quicker turnaround times.

Automation has also become a critical aspect of metal forming machinery. Automated systems reduce the need for manual labor, minimizing human error and increasing operational efficiency. With the rise of smart factories, manufacturers are now able to implement Industry 4.0 principles, utilizing IoT (Internet of Things) technologies to monitor and optimize metal forming processes in real-time.

Environmental sustainability has also become a consideration in the design and operation of metal forming machines. Many manufacturers are now focused on reducing waste and energy consumption, which not only benefits the environment but also improves profitability. Techniques such as recycling scrap metal and optimizing energy use during production are becoming standard practices within the industry.

In conclusion, metal forming machines are indispensable in shaping the future of manufacturing. As technology continues to advance, these machines are becoming more efficient, precise, and environmentally friendly. Their ability to create complex and robust components efficiently makes them a backbone of various industries, ensuring that manufacturers can meet the evolving demands of the market while maintaining high standards of quality and sustainability.