The metal deck cold bending machine has revolutionized the construction industry by providing an efficient and precise way to shape metal decks for various architectural and structural purposes. These machines offer a unique combination of Experience, Expertise, Authoritativeness, and Trustworthiness, making them pivotal in the intricate processes of modern construction.

Metal decking is critical in creating structural strength in composite floor slab systems, roof assemblies, and mezzanines. Traditional methods of bending metal decks often involved manual processes that were time-consuming, labor-intensive, and frequently resulted in inconsistencies that could compromise structural integrity. Enter the metal deck cold bending machine—a leap forward in terms of technological advancement and engineering execution.

With years of experience in machine manufacturing, companies specializing in cold bending technology have honed the design to meet the exact demands of the construction industry. These machines are engineered to handle a variety of metal deck profiles, bending metals of varying thicknesses and compositions with utmost precision. This capability reduces waste and increases efficiency, factors that significantly influence the bottom line of construction projects.

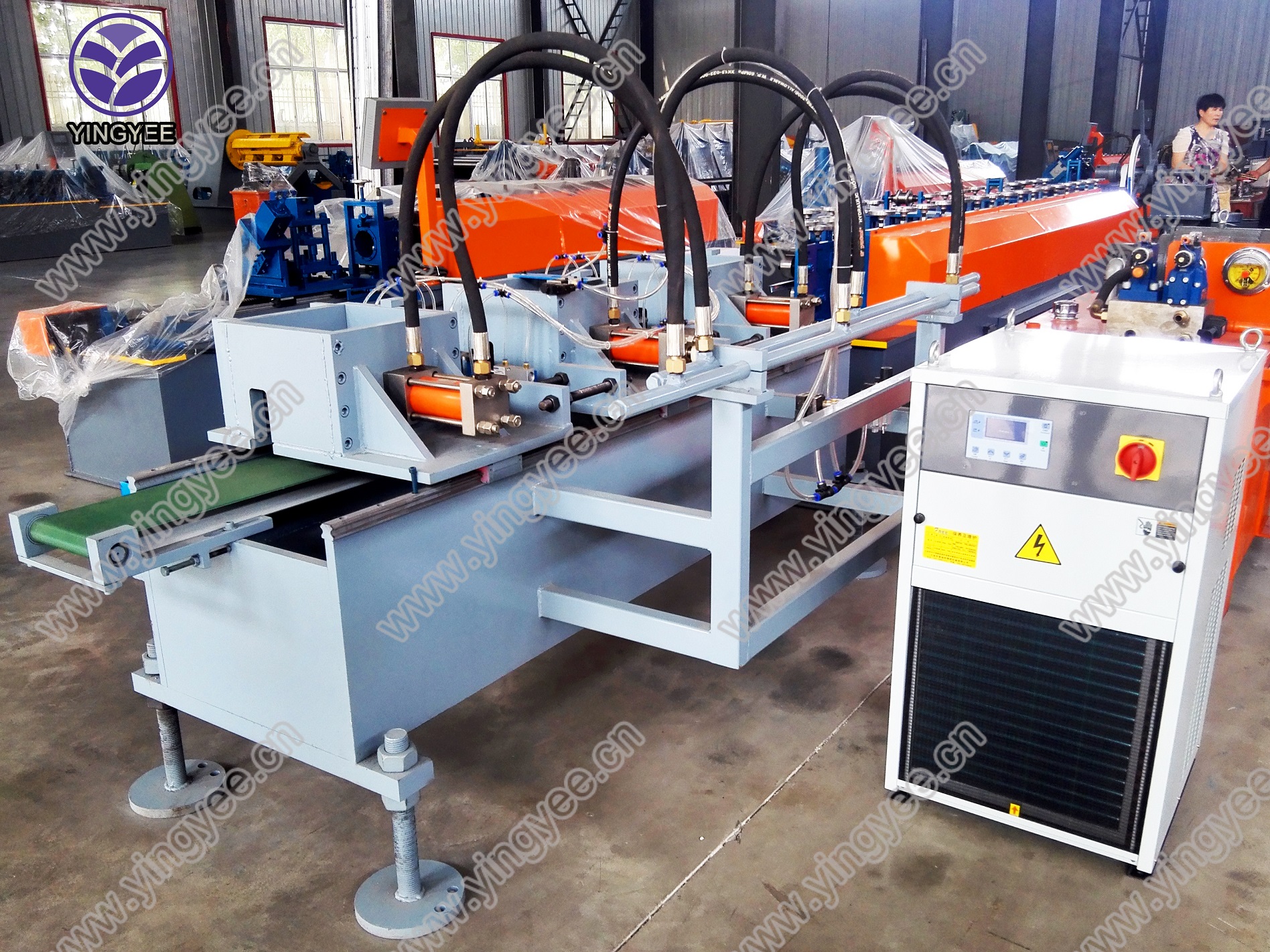

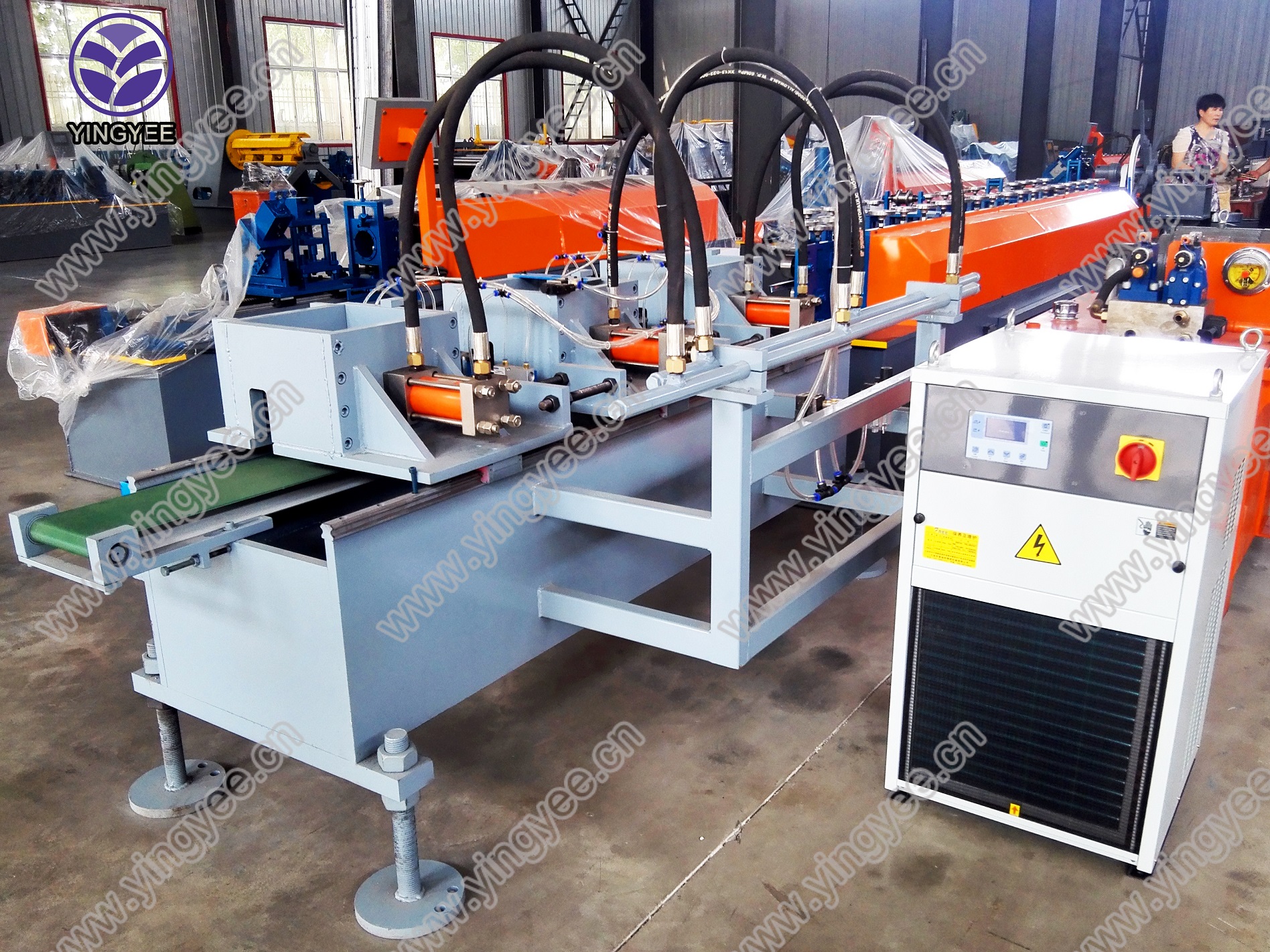

From an expert's perspective, a metal deck cold bending machine operates using advanced software that allows operators to program precise bend angles and radii into the control system. This level of precision ensures that each metal deck is bent consistently, minimizing the risk of structural failures and maximizing the lifespan of the construction. Such machines embody expertise not only in their mechanics but also in their adaptability, allowing for quick recalibration to accommodate different project needs without lengthy downtime.

metal deck cold bending machine

The authoritativeness of these machines does not merely rely on technical specifications but also on their capacity to influence manufacturing standards globally. By providing consistency in the production of metal decks,

cold bending machines set a benchmark that enhances the construction standards worldwide. They meet various international certifications and comply with rigid safety and quality standards, elevating them as essential equipment in any construction-related endeavor.

Trustworthiness is another critical aspect of these machines—a feature substantiated by rigorous testing and endorsements from industry professionals. When a construction firm invests in a metal deck cold bending machine, they are assured of its reliability and durability. Maintenance schedules are clearly defined and easily managed, resulting in minimal operational hiccups. Furthermore, established manufacturers provide comprehensive support and training for machine operators to ensure optimal utilization and safety.

In practical terms, adopting a metal deck cold bending machine in a construction line enhances the project's overall quality and time efficiency. Unlike older methods, which required extensive manpower and were prone to human error, these machines offer a seamless operation that can be integrated into any production timeline. The result is a swift turnaround time with high-quality outputs—an absolute necessity in today’s fast-paced construction industry.

In conclusion, the metal deck cold bending machine stands as a testament to the intertwined narratives of experience, expertise, authoritativeness, and trustworthiness in the construction machinery domain. Investing in such technology reflects a commitment to quality, efficiency, and innovation. As the construction landscape continues to evolve, these machines will undoubtedly remain at the forefront, offering new possibilities and setting new standards across the globe.