The metal curving unistrut roll forming machine is revolutionizing the construction and manufacturing industries by offering unmatched precision and efficiency. As a leading expert in industrial machinery, I am thrilled to share insights based on professional expertise and firsthand experiences with this groundbreaking equipment.

A metal curving unistrut roll forming machine specializes in the production of elegantly curved unistruts, which are ubiquitous in applications such as framing, support structures, and modular building systems. Unlike traditional straight unistruts, curved unistruts provide enhanced design flexibility, allowing architects and engineers to create more sophisticated and resilient frameworks.

From an experiential perspective,

operating a unistrut roll forming machine transforms not just the way metal frameworks are constructed but also how they perform under various conditions. This machine offers precise control of curvature, ensuring each piece meets rigorous structural and aesthetic requirements. Users can select from a range of radii to produce unistruts that perfectly match their project specifications, which is particularly beneficial for projects requiring high customization.

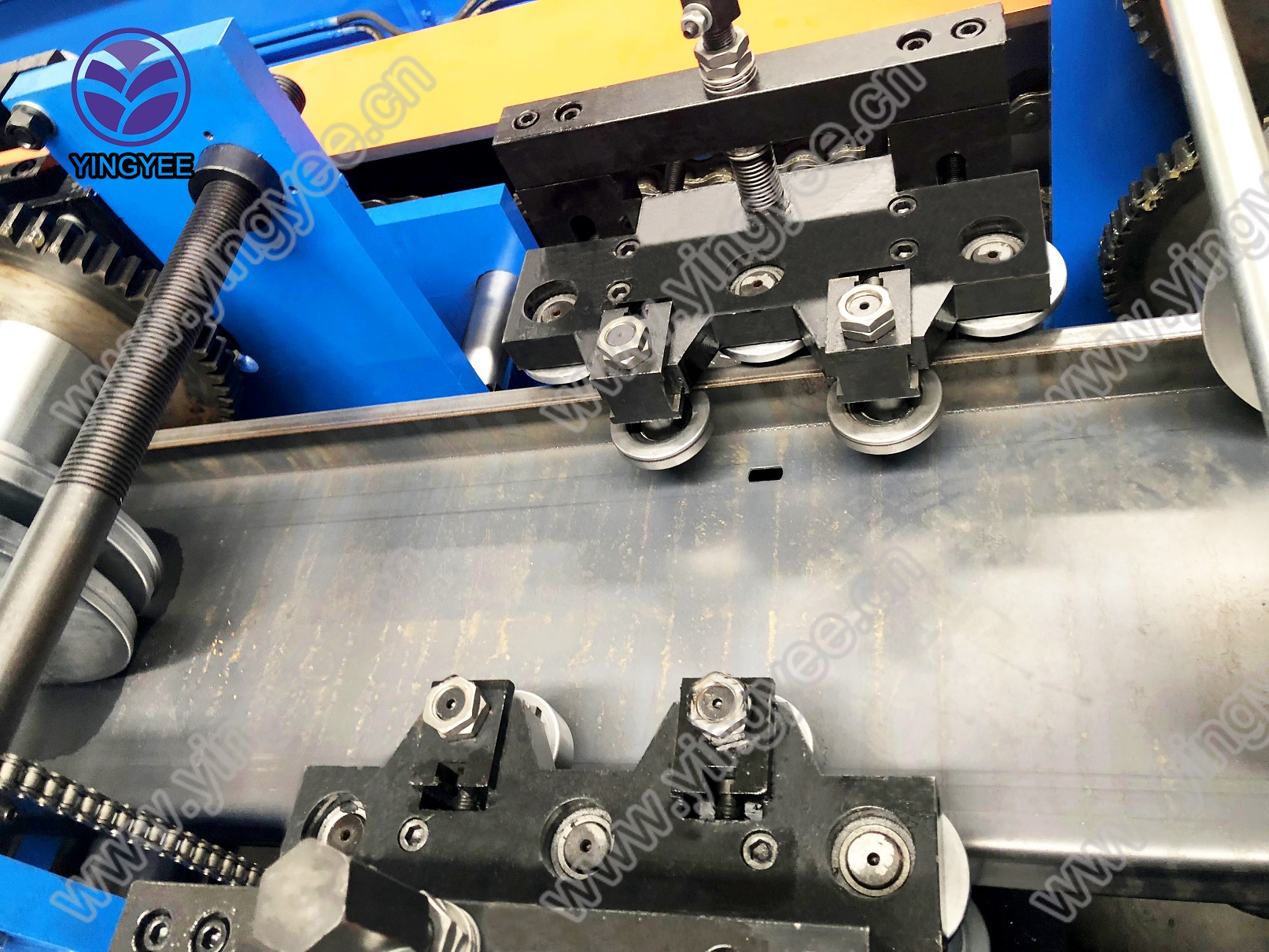

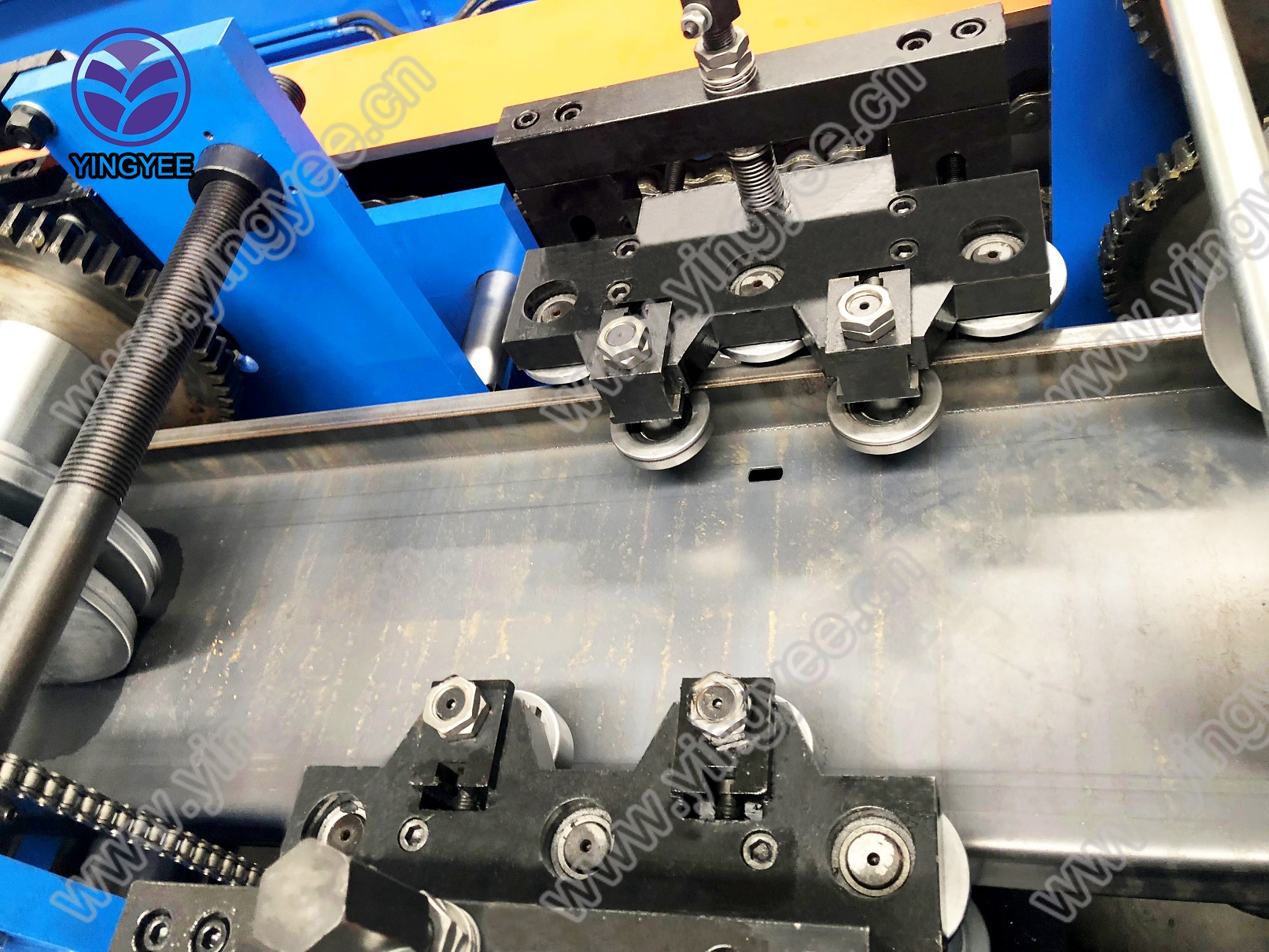

Professional expertise is paramount when discussing the operational aspects and advantages of the metal curving unistrut roll forming machine. These machines are engineered with cutting-edge technology to facilitate seamless transitions from unbending to curving processes, all while maintaining the mechanical properties of the metal. The durability of curved unistruts is unparalleled, as the machine’s consistent pressure application minimizes material stress and fatigue.

metal curving unistrut roll forming machine

One of the standout features of these machines is their intelligent control systems. Incorporating user-friendly interfaces and automated protocols, operators can easily program specific parameters, reducing the likelihood of human error. Additionally, the machine is designed with safety in mind, including fail-safes and emergency stops to protect both the operator and machinery.

From an authoritative angle, it’s crucial to recognize how these machines are reshaping industry standards. As environmental and economic factors push for more sustainable building practices, utilizing curved unistruts can significantly reduce material waste. By using precisely the required amount of material, companies can lower costs and decrease their carbon footprint. Industry leaders increasingly recommend the adoption of this innovative technology to remain competitive and sustainable.

In terms of trustworthiness, it is worth noting that this technology has been rigorously tested and approved by leading engineering bodies. Reputable manufacturers offer extensive warranties and support services, underlining their confidence in the reliability and longevity of their machines. Furthermore, training programs are often available to ensure that operators are well-versed in maintenance practices and the latest operational techniques, reinforcing the overall trust in this advanced machinery.

The future of building is set on a path that involves higher efficiency, precision, and aesthetic flexibility. Investing in a metal curving unistrut roll forming machine is not merely a purchase of advanced equipment—it represents a commitment to innovation, quality, and forward-thinking in the construction and manufacturing industries. Users and industry professionals alike can rely on these machines to deliver consistently exceptional results that align with both traditional and modern architectural demands.