Understanding Metal Channel Framing Roll Forming Machines

In the world of metal fabrication, the efficiency and quality of production processes hold paramount importance. One of the most innovative and pivotal tools enhancing this efficiency is the metal channel framing roll forming machine. This advanced machinery revolutionizes the way metal channels are produced, making it a staple in the construction, manufacturing, and automotive industries.

What is a Metal Channel Framing Roll Forming Machine?

A metal channel framing roll forming machine is designed to continuously shape flat metal sheets into specific channel profiles through a series of roller stations. The machine employs a process called roll forming, where the metal is fed through sequential rollers that gradually transform it into the desired shape. This method is preferred for its ability to produce complex profiles at high speeds while maintaining material integrity.

Applications of Metal Channels

Metal channels have a wide range of applications across various sectors. In construction, they serve as vital structural components, used in the framing of buildings, commercial spaces, and even residential properties. Their strength and durability make them ideal for supporting walls, roofs, and other elements. In the manufacturing sector, metal channels provide essential support for machinery and equipment. Additionally, metal channels play a significant role in the automotive industry, where they are used in body frames and chassis.

Benefits of Using Roll Forming Machines

1. Efficiency Roll forming machines can produce large quantities of metal channels in a relatively short time. The continuous process allows for minimal downtime, increasing overall productivity.

2. Precision One of the standout features of roll forming technology is its ability to produce consistent and precise shapes. This accuracy is crucial in industries where exact dimensions are required for structural integrity.

3. Material Utilization The process minimizes waste, as it typically utilizes a continuous strip of material. Any excess material can often be recycled on-site, further improving efficiency and reducing costs.

4. Customization Modern roll forming machines are versatile and can be easily adjusted to create a wide range of channel profiles and sizes. This adaptability allows manufacturers to meet diverse customer needs without requiring entirely new machinery.

5. Cost-Effective Although the initial investment in a roll forming machine may be significant, the long-term savings from reduced material waste, high-speed production, and lower labor costs make it a cost-effective choice.

Components of a Metal Channel Framing Roll Forming Machine

A typical metal channel framing roll forming machine consists of several key components

- Feeding Section This is where the flat metal sheets are fed into the machine. It can be equipped with various feeding mechanisms to ensure smooth and accurate material flow.

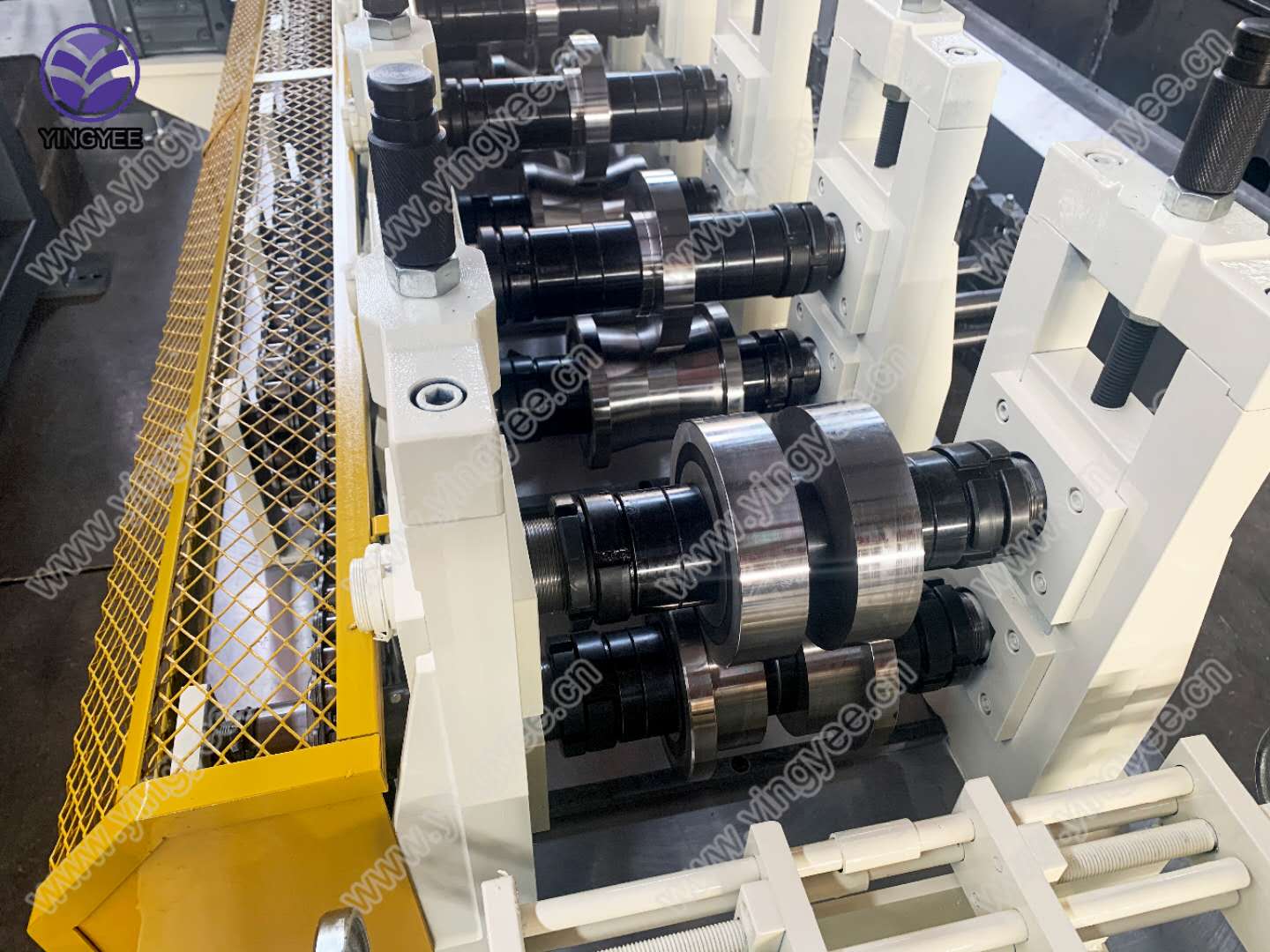

- Roll Tooling The heart of the machine, where the actual shaping occurs. Roll sets are specifically designed to create the required channel profile and can be swapped out for different designs.

- Cutting Mechanism After the metal has been formed, this component cuts it to length. This can be synchronized with the forming process for continuous production.

- Control System Modern machines often incorporate advanced control systems that allow operators to monitor and adjust the process parameters, including speed, temperature, and pressure, ensuring optimal performance.

Conclusion

The metal channel framing roll forming machine is an indispensable tool in metal fabrication, offering unparalleled efficiency, precision, and versatility. As industries continue to evolve and demand higher quality and faster production rates, roll forming technology will likely play an even more significant role. Understanding its operation and benefits can help stakeholders make informed decisions about their manufacturing processes, ultimately aiding in the growth and advancement of their respective sectors. Whether in construction, manufacturing, or automotive applications, investing in a roll forming machine can yield substantial returns in productivity and quality.