For those in the construction and building industries, efficiency and precision are paramount. The metal ceiling stud and track/drywall/C channel/main channel/wall angle roll forming machine emerges as a game-changer, epitomizing technological advancement in metal processing. This equipment transforms flat sheets of metal into meticulously shaped profiles designed for various structural applications, and its superiority is built on several pivotal attributes.

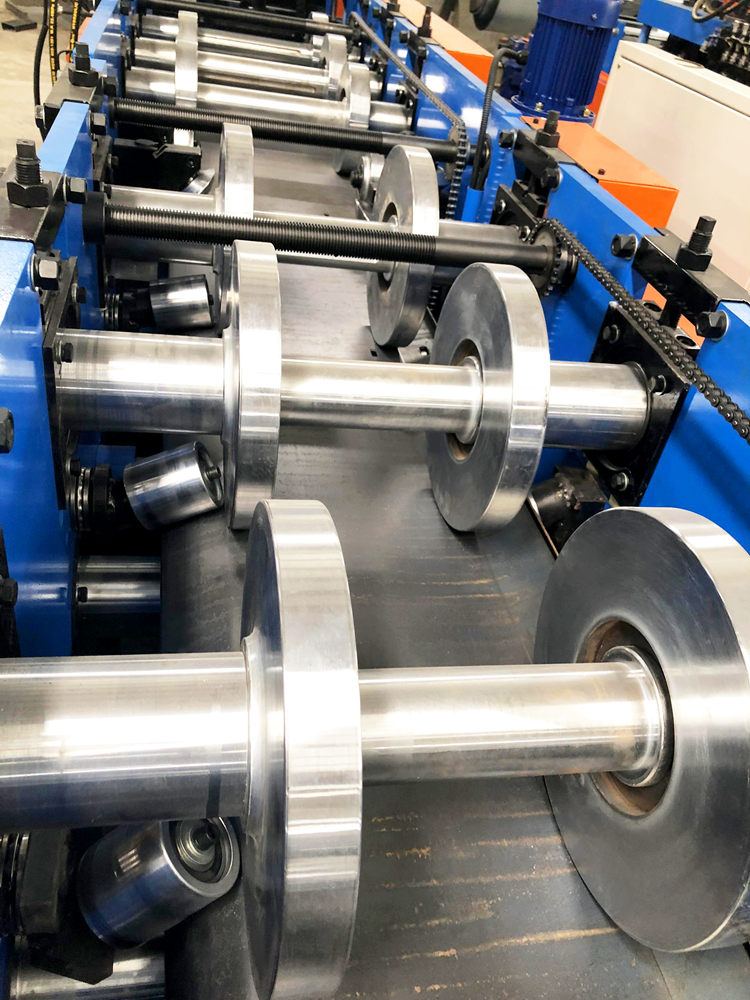

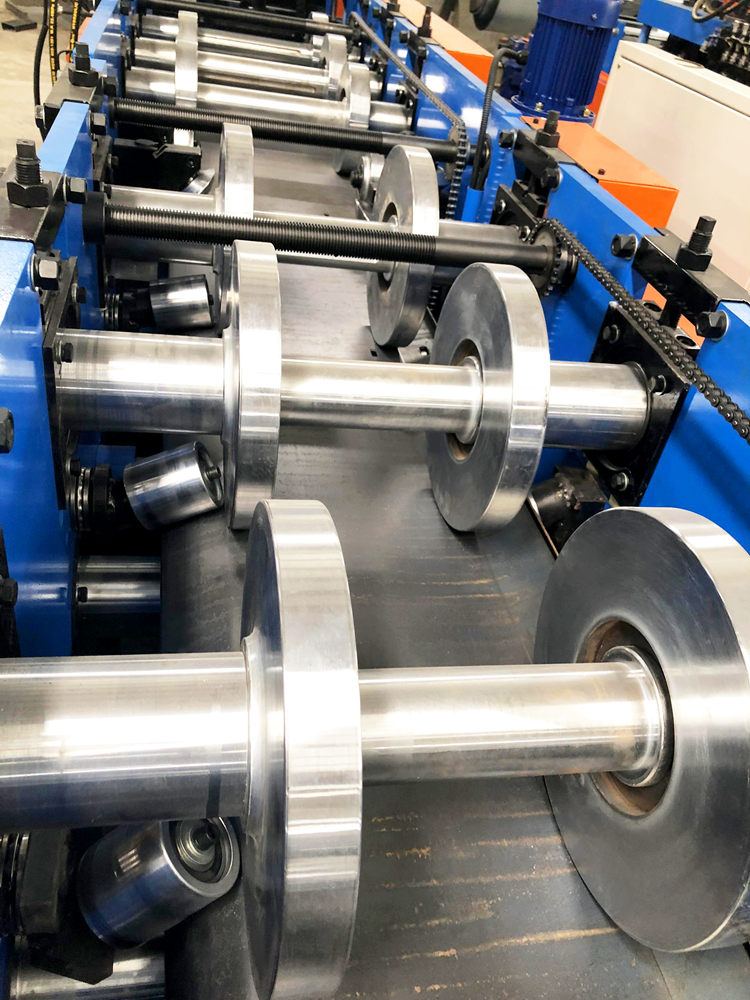

A hallmark of this roll forming machine is its precision. Every construction professional understands that the essence of a robust structure lies in its framework. An imprecise cut can lead to structural weaknesses, compromising safety and durability. This machine ensures that metal components have consistent dimensions and alignments, facilitating smoother installations where every component fits like a puzzle piece. This level of precision reduces manual corrections and accelerates the construction timeline, ultimately leading to cost savings.

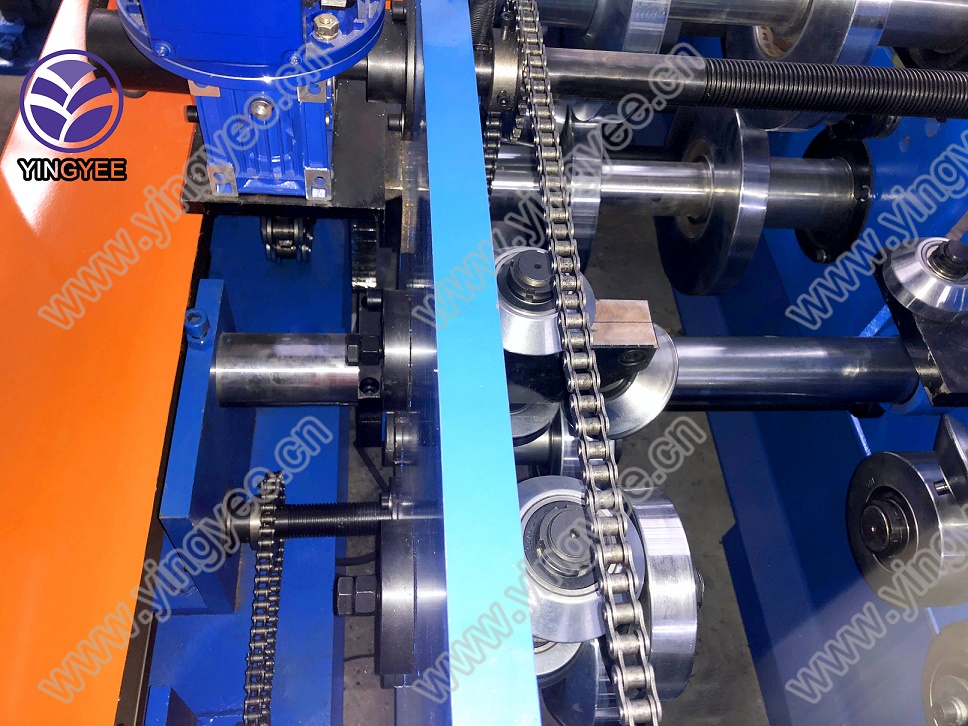

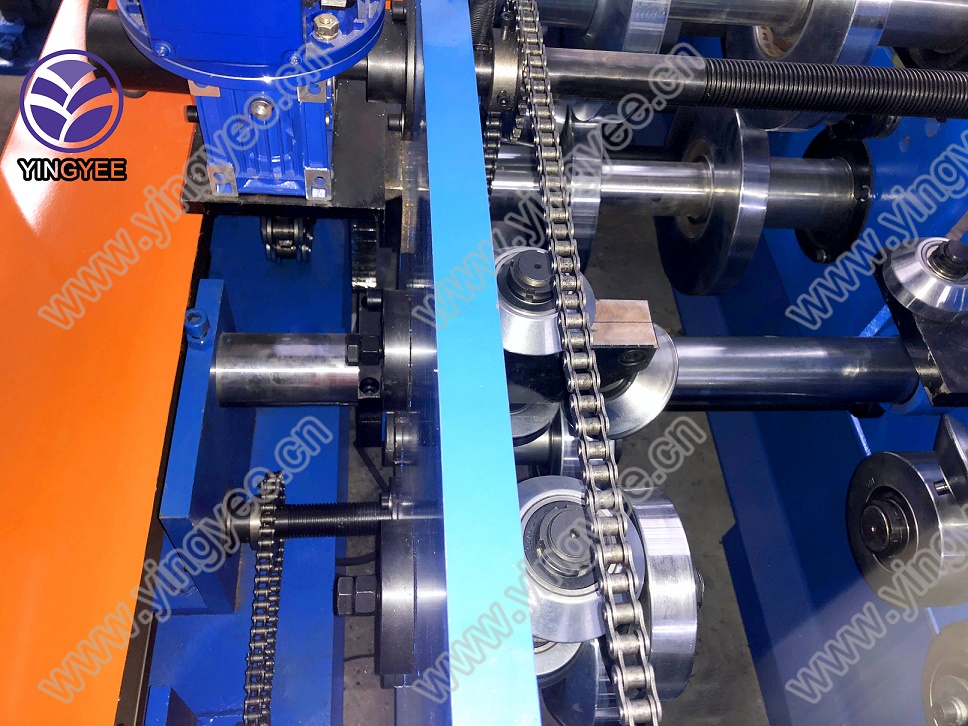

Equally critical to its precision is the machine's adaptability. Whether working with studs, tracks, drywall segments, C channels, main channels, or wall angles, this machine effortlessly translates diverse design requirements into tangible formats. The versatility afforded by the interchangeable roll sets allows users to adjust quickly between various product specifications. This adaptability means that builders can seamlessly navigate between projects requiring different metal profiles without lengthening production time. It's an undeniably efficient solution for contractors handling multiple projects with unique demands.

Durability and reliability further bolster this machine’s standing. Constructed using high-grade materials and backed by rigorous quality control measures, it withstands the rigors of continuous operation without frequent breakdowns. Users regularly marvel at its longevity and consistent performance, which translates to reduced maintenance costs and minimal downtime. In an industry where every second counts, having reliable machinery is a significant competitive advantage.

metal ceiling stud and track/drywall/c channel/main channel/wall angle roll forming machine

Beyond the physical construction benefits, this roll forming machine is also an exemplar of innovation in operation. Modern iterations are equipped with computerized control systems that enhance user experience through intuitive interfaces. Operators can input specific measurements and designs, and the machine will execute with unmatched accuracy. This software integration not only simplifies the user experience but also reduces the likelihood of human error, ensuring consistent product quality.

The commitment to sustainable practices is another facet where this roll forming machine shines. Its efficient design reduces wastage of metal materials, making it a more environmentally conscious choice compared to traditional processing methods. The precision cutting ability ensures that only the necessary amount of metal is used, minimizing scrap metal production and contributing to a more eco-friendly operation. Builders conscious of their carbon footprint will recognize this machine as aligning with green initiatives.

Safety, an often-overlooked aspect, is intricately woven into the machine’s design. With automatic shut-offs and user safety protocols, it minimizes the risk of accidents during operation. Construction sites are fraught with potential hazards, and reducing these risks with technologically advanced machinery creates a safer working environment, which is invaluable.

Ultimately,

the metal ceiling stud and track/drywall/C channel/main channel/wall angle roll forming machine is a testament to the evolution of industrial equipment. It sets benchmarks in precision, versatility, durability, innovation, sustainability, and safety—qualities that affirm its indispensability to professionals committed to excellence in the construction industry. As an instrument born out of expert knowledge and trusted by industry leaders, it serves not just as a tool but as an integral partner in successful building projects.