The Importance of Metal Ceiling Studs and Track Systems in Construction

In the realm of contemporary construction, metal ceiling studs and track systems have become indispensable components, enabling the efficient and durable installation of ceilings and walls. These systems are particularly favored for their strength, lightweight nature, and fire resistance, making them ideal for both commercial and residential projects.

What Are Metal Ceiling Studs and Track Systems?

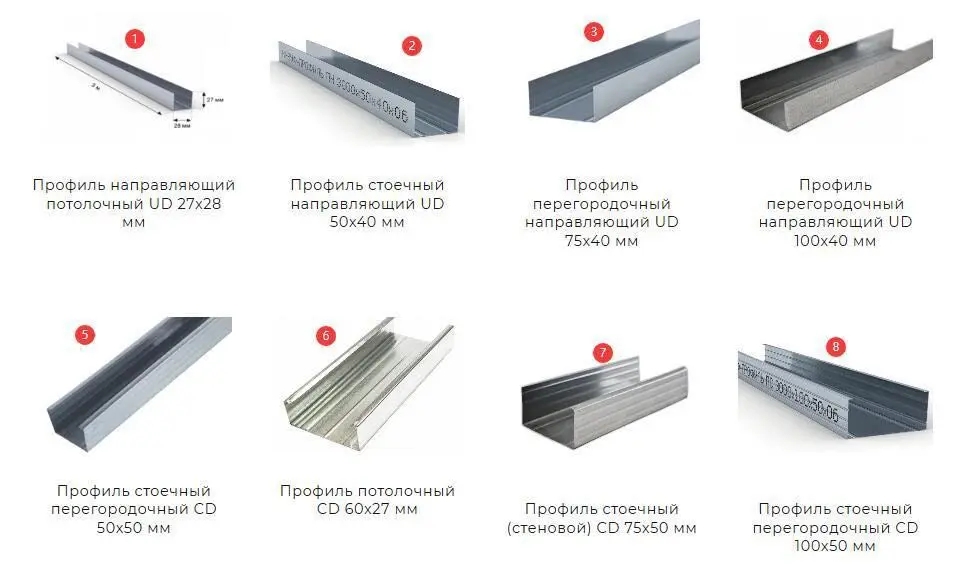

Metal ceiling studs are vertical framing members made from steel that are used to create the structure for a ceiling or wall. They are complemented by various track elements, such as C channels and main channels, which serve as horizontal supports. The wall angle serves as an essential component that connects the ceiling to the walls, providing stability and alignment. The entire system forms the skeleton upon which drywall and other finishing materials can be applied.

Advantages of Using Metal Components

1. Strength and Durability Metal studs are inherently stronger than their wooden counterparts. They do not warp, crack, or shrink, ensuring that your structures maintain their integrity over time. This durability is crucial in areas of high humidity or fluctuating temperatures, where wood may deteriorate.

2. Fire Resistance Steel is non-combustible, providing increased fire safety. Many building codes now require non-combustible materials in various construction types, making metal studs and tracks a smart choice for compliance.

3. Ease of Installation Metal studs and tracks are lightweight, making them easier to handle and install. With the right tools, contractors can quickly erect a framing system, thus decreasing labor costs and expediting project timelines.

4. Eco-Friendly Options Many metal framing products are made from recycled materials, contributing to sustainable building practices. They can also be recycled at the end of their lifecycle, making them an environmentally friendly option.

Roll Forming Technology in Metal Framing

The process of manufacturing metal studs and tracks involves advanced techniques such as roll forming. This method uses a series of rollers to shape flat metal sheets into specific profiles, ensuring precise dimensions and consistent quality across all components. The result is a product that delivers high performance and adaptability for various architectural designs.

Applications in Modern Design

Metal ceiling stud and track systems can be used in a wide range of applications, from commercial office buildings to residential homes. They are particularly advantageous in spaces where the aesthetic design is a priority, as they allow for various configurations and suspended ceiling systems. This flexibility means architects can achieve innovative designs while also ensuring structural stability.

Conclusion

In summary, the integration of metal ceiling studs, track systems, and roll forming technology represents a significant advancement in the construction industry. These components offer a robust solution for modern building needs, combining strength, fire safety, and ease of installation with aesthetic versatility. As construction practices continue evolving, the use of metal framing systems will likely become even more prevalent, further optimizing the efficiency and safety of building projects worldwide. For builders, architects, and contractors, understanding the capabilities and advantages of metal ceiling stud and track systems is essential in maximizing the potential of their projects.