Understanding Metal Standing Seam Roll Forming Machines

When it comes to the roofing industry, metal standing seam roofs have gained significant popularity due to their durability, longevity, and aesthetic appeal. To produce the specific profiles and high-quality materials needed for these roofs, manufacturers often turn to metal standing seam roll forming machines. These machines are engineered to produce interlocking metal panels that create a strong, watertight seal, providing excellent resistance to extreme weather conditions.

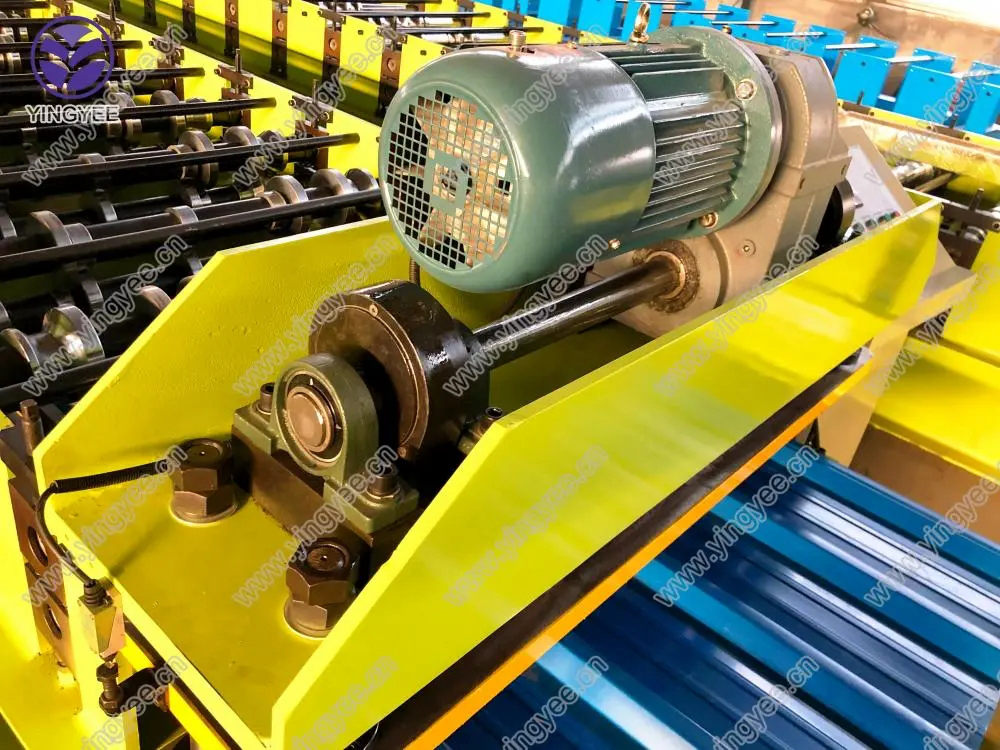

A metal standing seam roll forming machine operates by feeding a continuous strip of metal, typically steel or aluminum, through a series of rollers. These rollers gradually shape the metal strip into the desired profile. The process is designed for efficiency, allowing for high production rates and minimal waste. Additionally, the machine can be adjusted to create different seam heights and widths, accommodating various architectural designs and customer specifications.

One of the notable advantages of using a roll forming machine is the consistency it offers in production. The precision of the rollers ensures that every panel produced meets specific tolerances, which is crucial for maintaining structural integrity and aesthetic uniformity. This precision reduces the need for costly rework and can significantly lower production costs over time.

Moreover, modern standing seam roll forming machines are equipped with advanced technology, including programmable controls and automation features. This not only enhances the production speed but also allows manufacturers to easily switch between different panel designs without extensive downtime. Operators can quickly set parameters for new projects, making the process more versatile and responsive to market demands.

In terms of market trends, the demand for metal standing seam roofs continues to grow, particularly in residential and commercial sectors. This is driven by the increasing awareness of energy efficiency and sustainable building practices. Metal roofs reflect solar heat, helping to keep buildings cooler in the summer, and they often come with warranties that last 30 years or more.

In conclusion, metal standing seam roll forming machines play a pivotal role in the production of high-quality roofing materials. Their efficiency, precision, and adaptability make them essential tools for manufacturers looking to meet the evolving needs of the construction industry. As the popularity of metal roofs continues to rise, the importance of modern roll forming technology in delivering durable and aesthetically pleasing roofing solutions cannot be overstated.