Metal Deck Cold Bending Machines Revolutionizing Construction Efficiency

In the contemporary construction landscape, efficiency and precision are more critical than ever. One of the innovations that have made a considerable impact in this field is the metal deck cold bending machine. These machines are designed to create metal deck profiles for various building applications, including floors, roofs, and walls. By employing cold bending techniques, they deliver exceptional accuracy and speed, which significantly enhances construction productivity.

Cold bending, as opposed to traditional hot bending processes, involves shaping metal at room temperature. This method presents several advantages, particularly in terms of maintaining the steel's structural integrity. When metals are cold bent, they avoid the heat-induced changes in properties that can occur with hot bending. This results in a final product that retains its strength and durability, which are crucial characteristics in construction materials. The metal deck cold bending machine efficiently utilizes this process, allowing builders to achieve the desired shapes without compromising quality.

One of the most significant benefits of using a metal deck cold bending machine is the reduction in labor costs. Historically, bending metal sheets required significant manual labor and time, often leading to inconsistencies and errors. With the introduction of automated cold bending machines, the need for excessive manpower is alleviated. These machines can produce high volumes of accurately shaped metal decks in a fraction of the time, allowing construction projects to stay on schedule and within budget.

Moreover, these machines are versatile, accommodating various metal types and thicknesses. This adaptability is essential in modern construction projects, where the specific requirements can vary widely. Whether working with steel, aluminum, or other alloys, metal deck cold bending machines can be calibrated to deliver precise results tailored to the project needs. This versatility not only furthers efficiency but also ensures quality across different applications.

Another key advantage lies in the enhanced safety measures provided by metal deck cold bending machines. Automation reduces the need for workers to handle potentially dangerous tools and materials manually. As machines take on the heavy lifting, the risk of accidents is decreased, promoting a safer work environment.

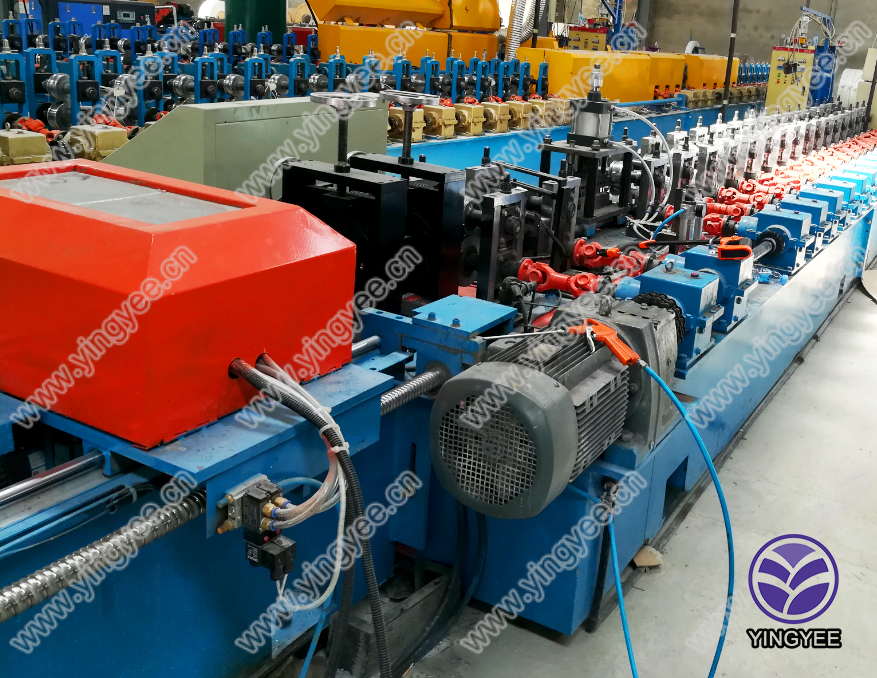

Furthermore, the design of modern metal deck cold bending machines incorporates advanced technology, enabling real-time monitoring and adjustments during the bending process. This ensures that any deviations from specifications can be promptly corrected, minimizing waste and enhancing overall product quality.

In conclusion, the metal deck cold bending machine stands as a testament to how technology can transform traditional construction methods. By improving efficiency, reducing labor costs, enhancing safety, and ensuring consistent quality, these machines are essential tools in the toolkit of modern builders. As construction continues to evolve, embracing innovations like cold bending technology will be vital in meeting the demands of future projects.