Understanding the Bending Machine and Its Applications

Bending machines are essential tools in various manufacturing and construction industries, facilitating the shaping of materials such as metal, plastic, and wood. These machines play a crucial role in achieving precise bends and configurations needed for different applications. With advancements in technology, the modern bending machine has evolved significantly, offering improved precision, efficiency, and versatility.

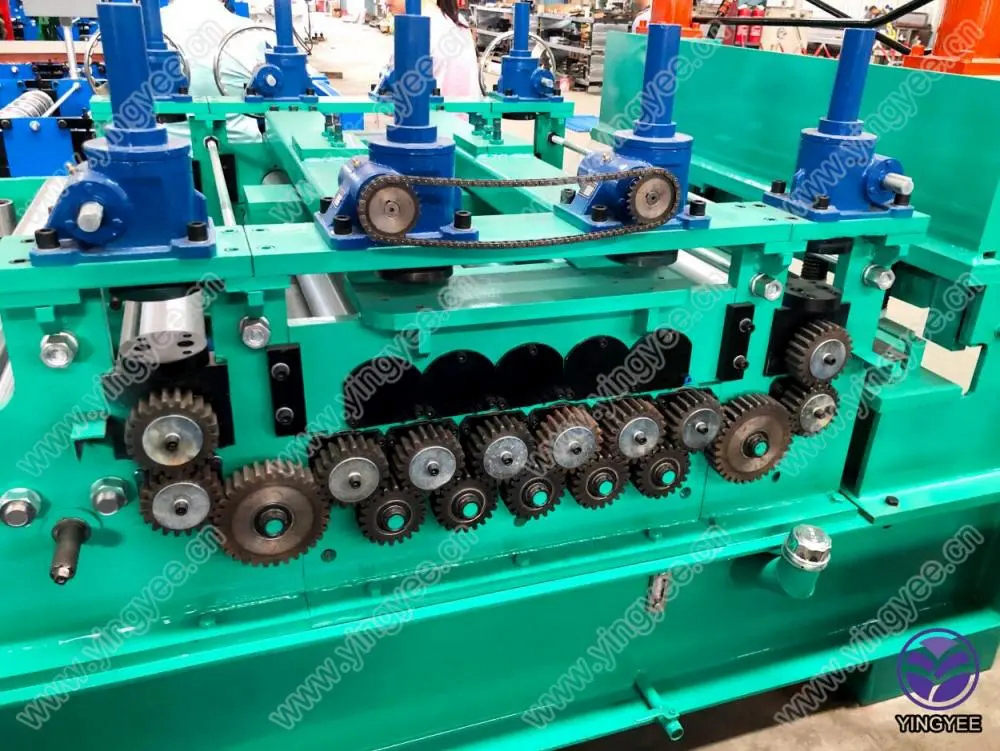

At its core, a bending machine operates by applying force to a material to create a permanent deformation. The fundamental principle involves using a die and a punch, where the material is placed on the die, and the punch exerts pressure to bend it into the desired angle. Various bending methods exist, including air bending, bottom bending, and roll bending, each suited to specific applications and material types.

Air bending is perhaps the most widely used technique, where the force is applied at the center of the material while the ends remain supported. This method allows for easy adjustments and is effective for lightweight materials. Bottom bending, on the other hand, involves applying pressure on the material until it makes contact with the bottom die, resulting in more accurate bends but requiring more initial setup.

Roll bending is commonly used for creating curved shapes and is particularly useful for large, cylindrical components. This method employs three rollers to gradually bend the material into the desired diameter, making it ideal for pipe manufacturing and large structural components.

In recent years, the integration of computer numerical control (CNC) technology into bending machines has revolutionized the way these machines operate

. CNC bending machines allow for automatic adjustments and programming, enabling operators to achieve intricate designs with minimal manual intervention. This not only increases efficiency but also reduces the risk of human error, enhancing the overall quality of the bent products.The applications of bending machines are vast and varied. In the automotive industry, for example, bending machines are utilized to shape metal components for vehicles, from frames to intricate brackets. In construction, they are essential for creating rebar and metal frameworks that provide structural integrity to buildings and bridges. Additionally, the HVAC industry relies on bending machines to form ductwork and other components necessary for efficient heating and cooling systems.

Safety is a paramount concern when operating bending machines. Operators must be trained to understand the risks associated with the machinery, including potential pinch points and the need for proper personal protective equipment (PPE). Regular maintenance and safety checks are critical to ensuring the machines operate smoothly and safely.

As industries continue to evolve, the demand for bending machines is expected to rise, driven by the need for customized and precision-engineered solutions. Innovations in materials and bending techniques will further enhance the capabilities of these machines, making them indispensable in modern manufacturing processes.

In conclusion, bending machines are vital to numerous industries, enabling the efficient and precise shaping of materials critical for various applications. With ongoing technological advancements, these machines will continue to play a crucial role in driving innovation and productivity in manufacturing and construction sectors. The future of bending technology looks promising, paving the way for even more sophisticated and efficient solutions.