The Mash TL2 Guardrail Cold Bending Machine A Game-Changer in Road Safety Infrastructure

In the realm of road safety infrastructure, the significance of guardrails cannot be overstated. These structures play a vital role in safeguarding both vehicles and pedestrians by preventing accidents and minimizing the impact of collisions. The Mash TL2 Guardrail Cold Bending Machine emerges as a transformative tool in this field, streamlining the production of guardrails while ensuring superior quality and efficiency.

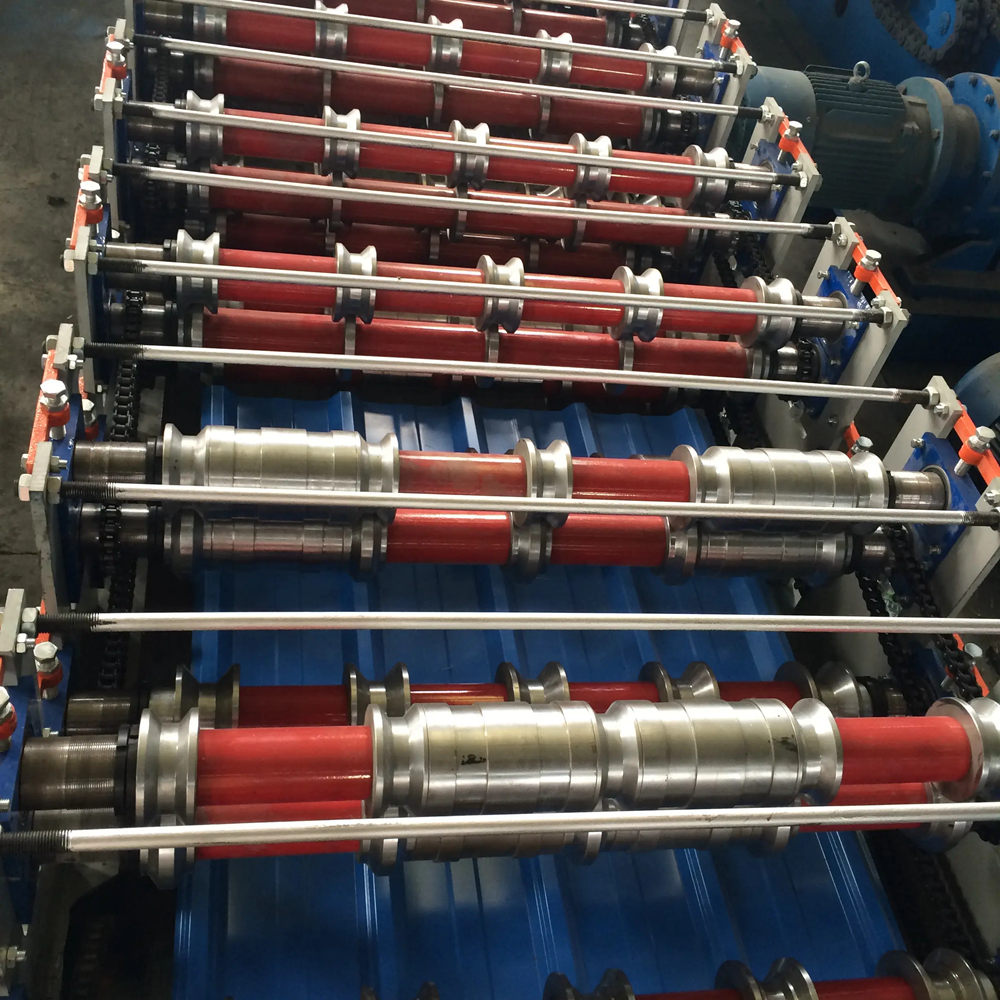

The Mash TL2 is designed specifically for bending and shaping guardrail materials with precision. Unlike traditional methods that often involve hot bending processes, which can compromise the integrity of the metal, the cold bending technology employed by the TL2 preserves the material's strength. This is crucial for maintaining the durability and effectiveness of guardrails in real-world applications. Cold bending not only reduces the risk of material fatigue but also leads to a more consistent product that adheres to industry standards.

Design and Functionality

One of the standout features of the Mash TL2 is its user-friendly design. The machine is equipped with an intuitive control panel, allowing operators to easily adjust settings according to the required specifications. This adaptability is particularly beneficial for manufacturers who produce guardrails in various shapes and sizes, as it facilitates a quick transition between different production lines.

Moreover, the TL2 incorporates advanced safety features, ensuring that operators can use the machine with confidence. Automatic shut-off systems, emergency stop buttons, and protective coverings work together to minimize the risks associated with machine operation. These features not only enhance the safety of the workplace but also increase overall productivity by enabling faster and more efficient workflows.

Economic Benefits

Investing in the Mash TL2 Guardrail Cold Bending Machine also comes with significant economic benefits. By enhancing production speed and reducing waste through precise bending techniques, manufacturers can lower their operational costs. Additionally, the longer lifespan of cold-bent guardrails minimizes the need for frequent replacements, providing long-term savings for infrastructure projects.

Furthermore, the ability to produce high-quality guardrails means that manufacturers can compete more effectively in the marketplace. The demand for reliable and durable guardrail solutions continues to grow, fueled by increased infrastructure investments globally. By utilizing the Mash TL2, companies position themselves to meet this demand while ensuring compliance with relevant safety regulations.

Conclusion

In summary, the Mash TL2 Guardrail Cold Bending Machine represents a significant advancement in the manufacturing of guardrails, enhancing both safety and efficiency. Its innovative cold bending technology, coupled with user-friendly design and economic advantages, make it a valuable asset for companies involved in road safety infrastructure. As the industry continues to evolve, tools like the TL2 will undoubtedly play a crucial role in shaping a safer future on our roads. By investing in advanced machinery, manufacturers can contribute to safer roadways, ultimately benefiting drivers and pedestrians alike.