The Evolution and Importance of Light Keel Roll Forming Machines

In the ever-evolving landscape of manufacturing and construction, innovation plays a pivotal role in enhancing productivity and efficiency. One of the remarkable advancements in this sphere is the development of light keel roll forming machines. These machines are integral to producing lightweight steel framing components, which are widely used in various construction applications, from residential to commercial buildings.

Light keel roll forming machines are specifically designed to produce light steel keel sections used in drywall and ceiling systems. The primary advantage of steel keels is their strength-to-weight ratio, which allows for robust construction without the associated burden of heavier materials. They can easily support gypsum board, resulting in a lightweight yet durable framework that meets modern building standards. As global demand for more efficient construction methods increases, the role of these machines becomes more significant.

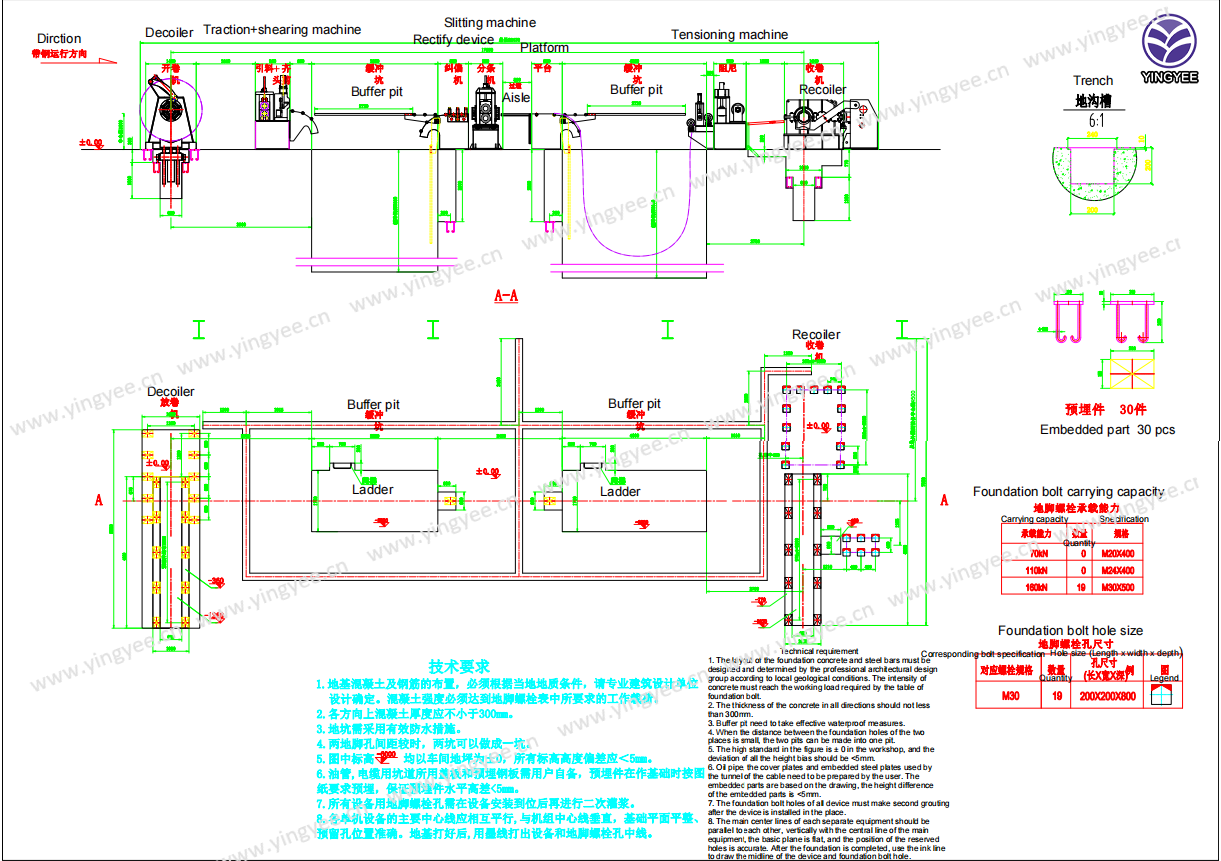

The manufacturing process of a light keel roll forming machine involves several key stages. Initially, a coil of steel is fed into the machine, which then forms it into the desired profile through a series of rollers. These rollers shape the steel into different configurations, such as U-shaped or C-shaped keels, depending on the specific requirements of the project. The precision of the roll forming process ensures that each component produced meets the exact specifications needed for easy assembly and installation.

One of the standout features of light keel roll forming machines is their automation capabilities. Modern machines are equipped with advanced control systems that allow for quick adjustments in the production line. This not only increases production efficiency but also minimizes material waste. By optimizing the forming process, manufacturers can significantly lower production costs and improve overall sustainability—a crucial aspect of today’s construction industry.

Moreover, the versatility of light keel roll forming machines makes them an invaluable asset in construction. They can produce a wide range of keel profiles with varying dimensions to cater to different structural requirements. This adaptability allows construction companies to efficiently respond to diverse project needs without investing in multiple machinery types, thereby streamlining operations.

The global market for roll forming machines is witnessing remarkable growth, driven by the ongoing urbanization and infrastructural development in emerging economies. As more builders and contractors recognize the benefits of using lightweight steel systems, the demand for light keel roll forming machines continues to rise. Manufacturers around the world are investing in research and development to enhance the features and capabilities of these machines, ensuring they keep pace with the increasing demands of the construction sector.

Additionally, advancements in technology have led to the introduction of software solutions that facilitate better design and planning. Construction professionals can now create digital models of their projects and fine-tune the specifications before the actual production begins. This not only enhances design accuracy but also leads to faster project completion times.

In conclusion, light keel roll forming machines represent a significant advancement in manufacturing technology, particularly in the construction industry. They offer an effective solution for producing lightweight, durable framing components that contribute to the efficiency and sustainability of building projects. As the industry continues to evolve, these machines will undoubtedly play a critical role in meeting the future demands of construction, paving the way for a new era of innovation in building techniques. Investing in these machines is not just a step towards modernization; it is a commitment to a more sustainable and efficient future in construction.