Main Furring Roll Forming Machine A Comprehensive Overview

In the world of construction and metal fabrication, the need for efficient and precise manufacturing processes is paramount. One of the standout machines in this regard is the main furring roll forming machine, which plays a crucial role in producing furring strips used in drywall and other construction applications. This article delves into the workings, benefits, and applications of the main furring roll forming machine, providing a clearer understanding of its significance in the industry.

Understanding Roll Forming

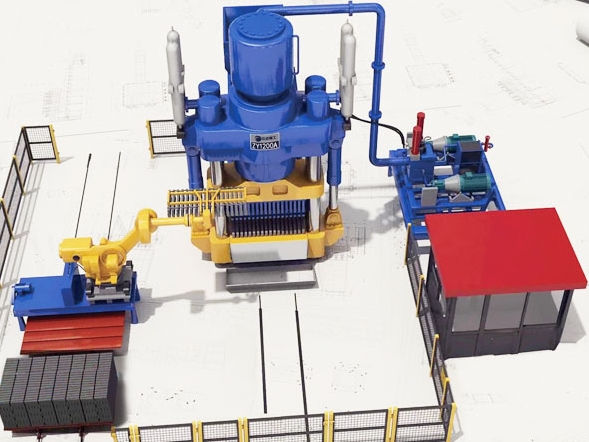

Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped in a series of stages through a set of rollers. This process allows manufacturers to produce complex cross-sectional profiles with remarkable consistency, precision, and speed. Among the various types of roll forming machines, the main furring roll forming machine is specifically designed to create furring channels — critical components in constructing walls, ceilings, and mounting systems for various surface materials.

Key Features of Main Furring Roll Forming Machines

1. Efficiency One of the primary advantages of using a main furring roll forming machine is its high production rate. Unlike traditional methods that may involve manual assembly or less efficient machinery, modern roll forming setups can produce thousands of linear feet of furring channels in a single day. This efficiency not only speeds up the construction process but also reduces labor costs.

2. Precision Engineering The automated nature of roll forming machines ensures that each furring strip produced meets strict design specifications. The machine's rollers are meticulously engineered to create consistent profiles, minimizing material waste and ensuring that every piece fits perfectly during installation.

3. Material Versatility Main furring roll forming machines can work with various materials, including steel, aluminum, and galvanized metal. This versatility makes them suitable for different construction projects, from residential buildings to large commercial structures.

4. Custom Design Capabilities Many modern machines can be customized to create specific profiles as required by architects and builders. This adaptability is crucial in today's construction landscape, where tailored solutions often outweigh one-size-fits-all designs.

5. Easy Operation and Maintenance Advanced furring roll forming machines come equipped with user-friendly interfaces and diagnostic systems that simplify operation and maintenance. Operators can easily monitor production metrics, identify potential issues, and perform necessary adjustments with minimal downtime.

Applications of Main Furring Roll Forming Machines

The primary application of main furring roll forming machines lies in the construction industry. Furring strips produced by these machines serve various purposes, including

- Support Structures Furring channels provide critical support for attaching wall and ceiling materials like drywall, ensuring a firm base that aids in the structural integrity of the finished project.

- Moisture Control By creating space between the drywall and the underlying surface, furring strips allow for airflow, which helps prevent moisture buildup and reduces the risk of mold growth.

- Thermal Insulation Furring strips can accommodate insulation materials, improving the thermal performance of walls and ceilings in both residential and commercial buildings.

- Aesthetic Applications In addition to their functional benefits, furring strips can be designed to enhance the aesthetic appeal of interior spaces, allowing for decorative paneling and ceiling designs that add visual interest.

Conclusion

The main furring roll forming machine is an indispensable tool in modern construction and metal fabrication. Its efficiency, precision, and versatility make it ideal for producing high-quality furring strips that meet the demands of various building projects. As the construction industry continues to evolve, the role of these machines in facilitating innovative, efficient, and sustainable building practices will undoubtedly grow, solidifying their position as essential components in the manufacturing landscape. As technology advances, we can expect even more enhanced features and capabilities in future furring roll forming machines, paving the way for superior construction solutions.