Main Furring Roll Forming Machine An Overview

In the ever-evolving construction industry, efficiency and precision are paramount. One of the key innovations that have greatly enhanced production capabilities for building materials is the main furring roll forming machine. This advanced equipment excels in the manufacturing of furring strips, which are essential for various construction applications, including walls, ceilings, and floors. This article aims to provide a comprehensive overview of the main furring roll forming machine, its functionality, and its significance in modern construction.

What is a Main Furring Roll Forming Machine?

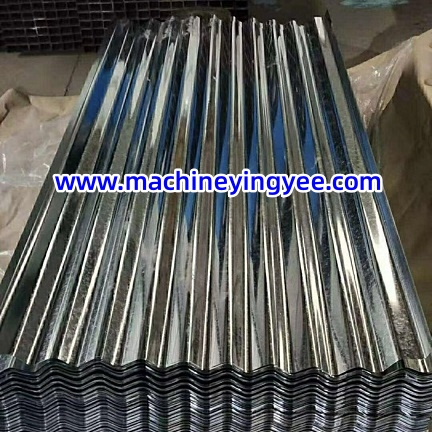

A main furring roll forming machine is a specialized piece of equipment designed to continuously roll metal sheets into specific profiles or shapes needed for furring strips. Furring strips are typically made from steel or aluminum, and they serve as a framework that creates space between the surface of a wall or ceiling and the material being installed, such as drywall. This space is crucial for electrical wiring, insulation, or plumbing, and aids in achieving a smooth finish.

How Does It Work?

The operation of the main furring roll forming machine is a technically sophisticated process. Initially, coils of metal sheets are fed into the machine, where they undergo a series of rolling operations. The machine consists of multiple sets of rollers that gradually shape the flat metal into desired profiles. Each pass through the rollers adjusts the metal's shape slightly, allowing for high levels of precision.

Once the metal has acquired the necessary profile, it is cut to length according to defined specifications. The cutting system can be synchronized with the roll forming process to ensure continuous production without interruptions. Additionally, many modern machines are equipped with computerized controls that allow for easy adjustments to specifications, enabling manufacturers to produce customized furring strips for varying applications.

Benefits of Using a Main Furring Roll Forming Machine

1. Efficiency One of the most significant advantages of this technology is its high level of efficiency. Traditional methods of producing furring strips may involve more labor and time, while roll forming automates the process, significantly speeding up production.

2. Consistency and Precision The roll forming process allows for tight tolerances and high consistency in the shapes produced. This precision is crucial in construction, where every millimeter counts to ensure proper installation and aesthetic appeal.

3. Material Utilization Roll forming maximizes material utilization, minimizing waste. The continuous production process allows for longer lengths of product to be manufactured from less material, leading to cost savings and more eco-friendly production practices.

4. Versatility Modern main furring roll forming machines can produce a variety of profiles, accommodating different project requirements. Manufacturers can quickly switch between profiles, allowing for flexibility in operations.

5. Durability Furring strips produced through roll forming are often stronger and more durable than those created through traditional methods. The consistent thickness and quality of the material enhance the structural integrity of finished installations.

Conclusion

In conclusion, the main furring roll forming machine represents a significant advancement in the manufacturing of furring strips, which are integral to modern construction practices. By combining efficiency, precision, and versatility, these machines not only improve production capabilities but also enhance the quality of construction materials. As the construction industry continues to demand higher standards and faster turnarounds, the role of advanced machinery like the main furring roll forming machine will undoubtedly become more critical, paving the way for innovative building solutions.