The Efficiency and Benefits of Main Channel Machines with Good Forming Effect

The manufacturing industry has witnessed remarkable advancements in technology, especially when it comes to the machinery used for production processes. Among the various types of machines, the main channel machine is gaining recognition due to its exceptional forming effect and efficiency. This article explores the features, advantages, and applications of main channel machines in industrial settings.

Understanding Main Channel Machines

Main channel machines are specialized equipment designed to produce specific shapes and forms from various materials, primarily metals and plastics. These machines utilize molds and dies to ensure that the end product meets precise specifications. What sets main channel machines apart is their capacity to achieve a high level of consistency and accuracy in the forming process, resulting in superior quality products with minimal waste.

Good Forming Effect Key Features

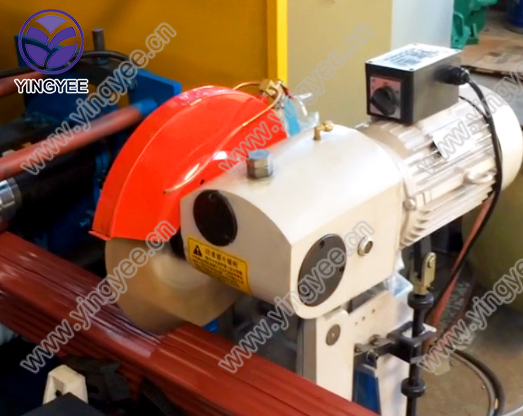

One of the defining characteristics of main channel machines is their good forming effect. This refers to the machine’s ability to transform raw materials into desired shapes effectively. The technology behind these machines typically involves several components, including hydraulic systems, programmable logic controllers (PLCs), and advanced software for design and operation.

1. Hydraulic Systems Many main channel machines employ hydraulic systems that deliver high pressure and force during the forming process. This ensures that the material is shaped uniformly, which is crucial for achieving products with exact dimensions.

2. Programmable Logic Controllers PLCs allow for automation in the forming process, providing operators with the ability to control various parameters such as pressure, speed, and temperature. This level of control directly impacts the forming effect, ensuring that each operation is executed with precision.

3. Advanced Software Modern main channel machines are equipped with sophisticated software that facilitates the design of molds and die-cutting processes. This software enables efficient simulations, allowing manufacturers to forecast outcomes before actual production begins.

Advantages of Using Main Channel Machines

The use of main channel machines comes with several advantages, specifically relating to productivity and quality.

1. Enhanced Efficiency Main channel machines can produce large quantities of products in a shorter time span. The automation and precision offered by these machines streamline production processes, significantly reducing lead times.

2. Improved Product Quality The good forming effect ensures that every unit produced adheres to strict quality standards. This is particularly important in industries like automotive and aerospace, where even minor defects can result in severe consequences.

3. Cost-Effective Production While the initial investment in main channel machines may seem high, the long-term savings due to reduced waste, decreased labor costs, and higher production efficiency often outweigh the costs. This makes them an excellent choice for businesses focused on maximizing return on investment.

4. Versatile Applications Main channel machines are versatile and can be used in various sectors, including automotive manufacturing, construction, electronics, and consumer goods. Their ability to work with different materials adds to their appeal across industries.

Applications in the Manufacturing Sector

Main channel machines are integral to various manufacturing processes. In the automotive industry, they are used to produce components like chassis, frames, and intricate parts that require precision engineering. In the construction sector, these machines facilitate the creation of various structural elements. Similarly, in electronics, they play a pivotal role in manufacturing casing and components that require lightweight yet robust materials.

Conclusion

The main channel machine with good forming effect epitomizes the evolution of manufacturing technology. Its ability to produce high-quality products efficiently makes it an indispensable tool in modern production environments. As industries continue to embrace automation and advanced manufacturing processes, the relevance of main channel machines will only increase, driving further innovation and productivity across various sectors. Investing in such technology represents a forward-thinking approach that many manufacturers are adopting to stay competitive in an ever-evolving marketplace.