The T-Bar Ceiling Frame Making Machine Revolutionizing Interior Construction

In the ever-evolving world of construction and interior design, efficiency and precision are pivotal. One of the standout innovations that has caught the attention of industry professionals is the T-Bar ceiling frame making machine. This cutting-edge equipment plays a crucial role in the production of T-bar ceiling systems, which are widely used in commercial and residential spaces.

Understanding T-Bar Ceilings

T-Bar ceilings, commonly known as suspended ceilings, consist of a grid framework that supports ceiling tiles in place. These ceilings not only enhance the aesthetic appeal of a room but also provide significant functional benefits such as sound absorption, thermal insulation, and easy access to overhead utilities like electrical wiring and plumbing. The grid system is vital for ensuring a seamless fit for the ceiling tiles, making the accuracy of the T-Bar framework essential.

The Role of the T-Bar Ceiling Frame Making Machine

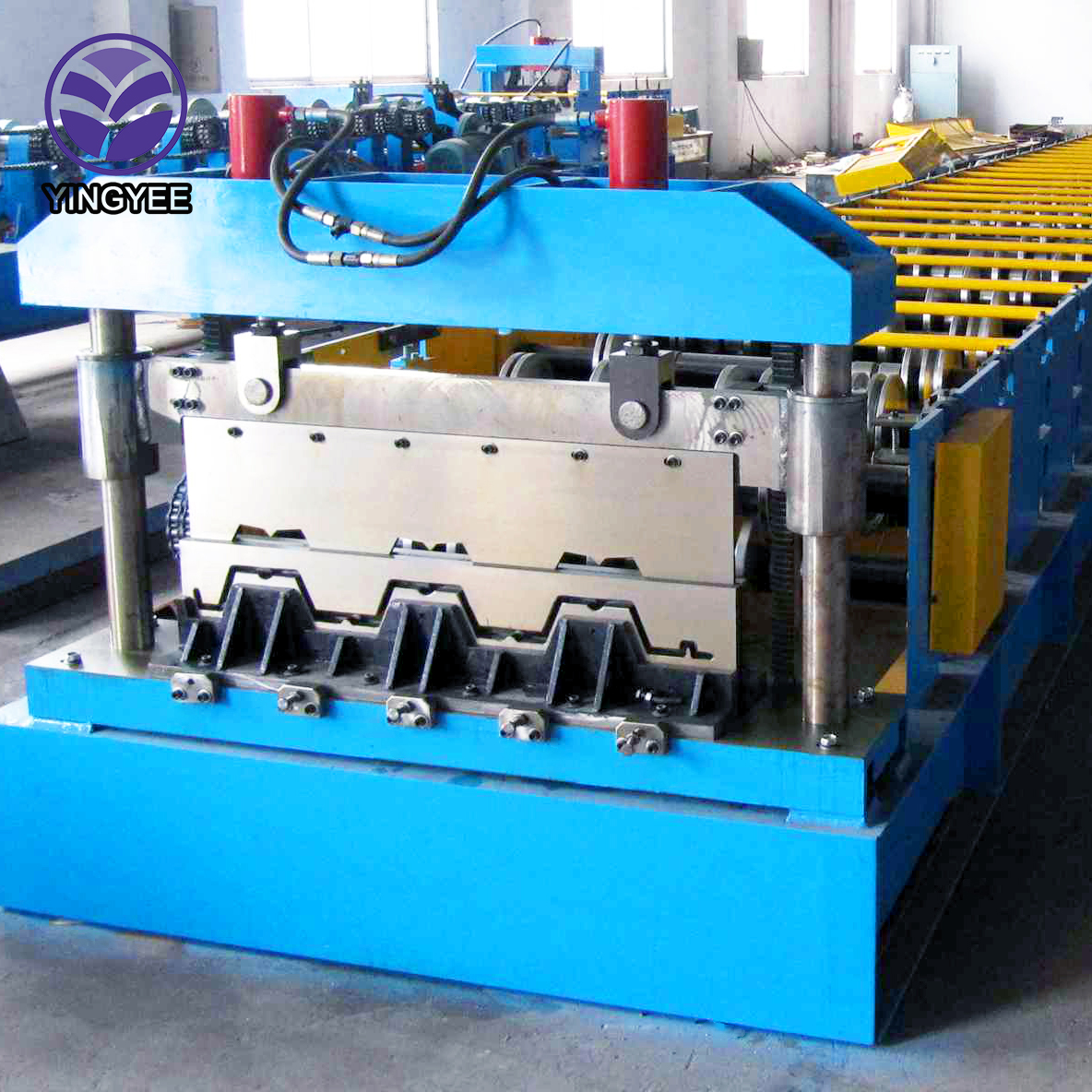

The T-Bar ceiling frame making machine automates the production process of these grid systems, which includes cutting, bending, and assembling the required components. This machine is designed to fabricate T-profiles with precision, enabling contractors to install ceilings more efficiently and with higher quality results. By streamlining the manufacturing process, it reduces labor costs and time, making project execution faster and more cost-effective.

Key Features and Benefits

1. Precision Engineering The T-Bar ceiling frame making machine is equipped with advanced technology that ensures precise dimensions of the T-bars. This accuracy minimizes the need for adjustments during installation, thus speeding up the overall project timeline.

2. Versatility Many T-Bar frame machines can produce various profiles and sizes to accommodate different ceiling designs. This versatility allows manufacturers to cater to a wide range of client requirements, whether they're designing office spaces, retail stores, or residential homes.

3. Reduced Waste Traditional methods of making ceiling frames often lead to significant material waste due to inaccuracies or improper cutting. Modern machines are designed to optimize material usage, resulting in a more sustainable production process.

4. Improved Safety Automation reduces the need for manual handling of heavy materials, thus decreasing the risk of workplace injuries. Operators can manage the machine settings and monitor the production process from a safe distance.

5. Cost Efficiency While the initial investment in a T-Bar ceiling frame making machine may be substantial, the long-term savings in labor costs, reduced waste, and faster project completion times make it a wise investment for construction companies.

Future Prospects and Innovations

As technology continues to advance, the capabilities of T-Bar ceiling frame making machines are expected to improve further. Innovations such as enhanced automation, integration with manufacturing software, and real-time monitoring systems will likely reshape the way these machines operate. Additionally, the trend towards eco-friendly materials and production processes will influence future designs, allowing manufacturers to create more sustainable and energy-efficient ceiling solutions.

Conclusion

The T-Bar ceiling frame making machine stands as a testament to the significance of automation in the construction industry. By improving the precision, efficiency, and safety of T-Bar frame production, this machine not only enhances the quality of finished ceilings but also contributes to the overall success of construction projects. As the industry continues to embrace new technologies, the future looks promising for interior construction methods, paving the way for innovative designs and approaches to space utilization. For contractors and manufacturers alike, investing in such technology is not just an option; it is becoming a necessity in today’s competitive market.