The Significance of a Machine for Forming Metal Studs with Good Forming Effect

In the realm of manufacturing and construction, metal studs have become essential components due to their strength, durability, and lightweight characteristics. The demand for efficient and precise production methods has led to the development of advanced machines for forming metal studs. A machine designed specifically for this purpose not only enhances productivity but also ensures consistent quality and improved forming effects, which are crucial for various applications.

Key Features of Metal Stud Forming Machines

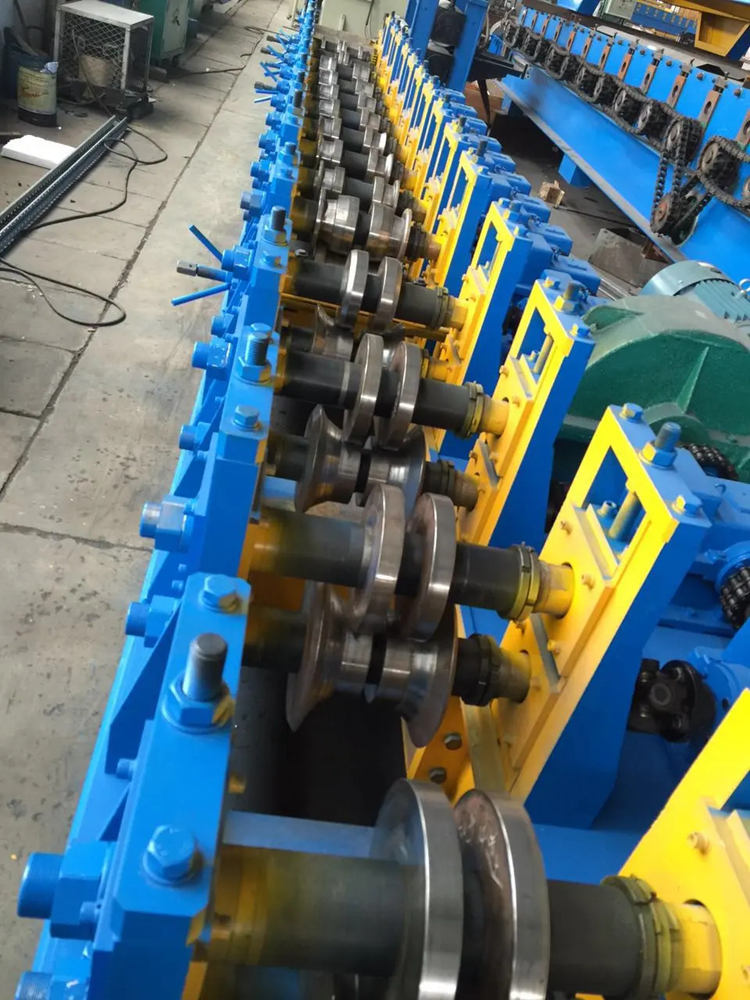

Metal stud forming machines are specialized equipment that can produce a wide range of metal studs efficiently. These machines often incorporate advanced technologies such as programmable logic controllers (PLCs), servo motors, and high-speed processing capabilities. The precision and control offered by such technologies allow manufacturers to create studs with tight tolerances and specific geometries, meeting the industry's rigorous standards.

One of the primary advantages of these machines is their ability to produce metal studs with excellent forming effects. This refers to the machine's capacity to manipulate and shape the metal accurately without compromising its structural integrity. Achieving good forming effects is critical, as it affects not only the aesthetic appeal of the studs but also their performance in applications such as wall framing and support structures.

Advantages of Good Forming Effects

The significance of good forming effects cannot be overstated. First, well-formed metal studs provide enhanced strength, which is crucial for structural applications. When the studs are formed correctly, they can withstand greater loads, resist deformation, and ensure the stability of the structures they support.

Secondly, good forming effects lead to reduced material wastage. Effective machines minimize the need for rework and scrap by ensuring that each stud is produced accurately to specifications. This efficiency translates into cost savings for manufacturers, allowing them to allocate resources more effectively.

Additionally, when metal studs are formed properly, they fit together seamlessly during assembly. This allows for quicker and easier installation, reducing labor time and improving overall project timelines. In construction, where time is of the essence, expedited assembly can significantly impact project completion and profitability.

Conclusion

In conclusion, the machine for forming metal studs with good forming effects plays a pivotal role in modern manufacturing and construction. As the demand for reliable and efficient building materials continues to rise, investing in advanced forming machinery becomes increasingly important. These machines not only enhance the quality and performance of metal studs but also contribute to greater operational efficiency and cost-effectiveness. Investing in high-quality forming machines is essential for businesses looking to thrive in a competitive market, ensuring they can meet the evolving needs of construction and manufacturing sectors. The transition to these advanced technologies signifies a commitment to quality and innovation, ultimately shaping the future of metal construction.