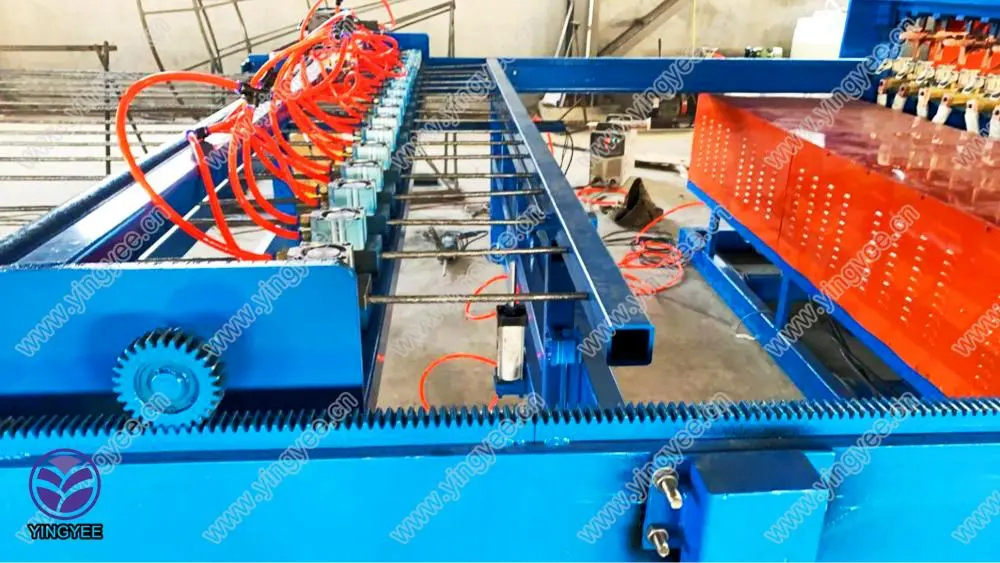

Low Defective Rate Gypsum Stud Roll Forming Machine A Game Changer in Construction

In recent years, the construction industry has witnessed significant technological advancements aimed at improving efficiency and quality. Among these innovations, the low defective rate gypsum stud roll forming machine stands out as a revolutionary tool that offers numerous benefits to builders and contractors.

Gypsum is an essential material used in various construction processes, particularly in the production of drywall and partitions. Traditionally, the manufacturing of gypsum studs involved intricate manual processes and heavy machinery, often leading to high defect rates and wasted materials. However, with the introduction of low defective rate gypsum stud roll forming machines, these issues are becoming a thing of the past.

One of the primary advantages of using a roll forming machine is its ability to produce high-quality gypsum studs consistently. The machine utilizes advanced technology to ensure precise dimensions and uniformity throughout the production process. This precision is crucial in construction, where even minor deviations can lead to significant setbacks and increased costs. The roll forming process minimizes human error, thereby reducing the likelihood of defective products.

Moreover, the low defective rate associated with these machines significantly enhances material efficiency. In traditional methods, excess materials often go to waste due to defects, but with a specialized roll forming machine, the material yield is optimized. This reduction in waste not only lowers production costs but also contributes to more sustainable construction practices, a growing concern in today’s eco-conscious market.

Another key benefit of the low defective rate gypsum stud roll forming machine is its speed and efficiency. The automated nature of the machine allows for rapid production, enabling builders to meet tight project deadlines without compromising quality. Additionally, the machine’s user-friendly design often means less training time for operators, further streamlining the production process.

Furthermore, the durability of the gypsum studs produced by these machines is noteworthy. The advanced manufacturing techniques employed ensure that the studs are not only lightweight but also strong and capable of withstanding various environmental factors. This durability translates into longer-lasting structures, which is a significant selling point for contractors and builders.

Finally, the introduction of low defective rate gypsum stud roll forming machines signifies a shift towards modern, efficient manufacturing practices in the construction industry. As companies continue to seek ways to improve their workflows and reduce waste, such machines represent the forefront of innovation. By embracing this technology, builders can enhance their operational efficiency, maintain quality standards, and ultimately, deliver superior results to their clients.

In conclusion, the low defective rate gypsum stud roll forming machine is indeed a game changer. Its ability to produce high-quality, durable products with minimal waste not only fulfills the demands of the modern construction industry but also promotes sustainability. As this technology continues to evolve, it will undoubtedly redefine manufacturing standards and practices, paving the way for a more efficient and environmentally friendly future in construction.