Long Span Roll Forming Machine An Overview

In the realm of modern manufacturing, efficiency and precision are paramount. One of the key innovations that has revolutionized the production of long, continuous metal sections is the long span roll forming machine. This sophisticated piece of equipment plays a crucial role in various industries, including construction, automotive, and manufacturing, by enabling the creation of high-quality products with remarkable speed and consistency.

What is a Long Span Roll Forming Machine?

At its core, a long span roll forming machine is designed to convert flat metal sheets or coils into complex profiles and shapes through a continuous bending process. Unlike traditional fabrication methods that may involve cutting and welding, roll forming offers a seamless production process that significantly reduces material waste and enhances structural integrity. The term “long span” refers to the capability of the machine to produce extended lengths of profiles, making it ideal for applications such as roofing, structural supports, and panels.

Key Components and Operation

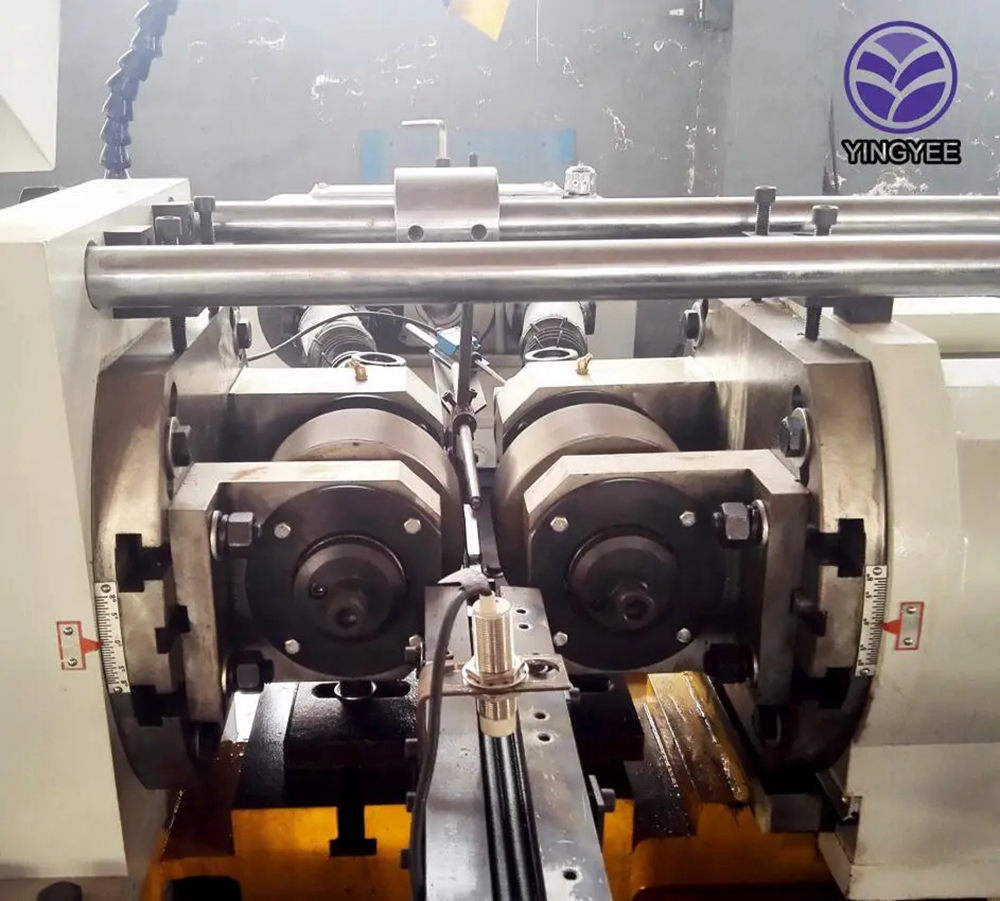

A long span roll forming machine consists of several key components, including a decoiler, forming rollers, a cutting mechanism, and a control system. The process begins with feeding the metal coil into the decoiler, which unwinds the metal sheet as it moves forward. The sheet is then fed into a series of rollers that progressively shape it into the desired profile. Each roller performs a specific function, gradually bending the metal until it reaches the final shape.

Once the desired profile is achieved, the cutting mechanism comes into play. Depending on the specifications, the machine can cut the profiles to predetermined lengths, ensuring consistency across all produced items. Advanced control systems allow operators to input various parameters, adjusting the machine's speed and settings for different profiles, which increases flexibility and efficiency.

Advantages of Long Span Roll Forming Machines

The benefits of using a long span roll forming machine are numerous. One of the most significant advantages is the reduced material waste. The continuous nature of roll forming minimizes scrap material, leading to cost savings and a more sustainable production process. Additionally, the ability to produce long lengths of profile reduces the need for multiple joints or welds, further enhancing the strength and durability of the final product.

Speed is another critical advantage. Long span roll forming machines operate at high speeds, allowing manufacturers to increase their output without sacrificing quality. This efficiency is especially beneficial in industries with high demand, where meeting production quotas quickly and reliably is essential.

Moreover, the precision of roll forming is unparalleled. The machine's ability to produce consistent, uniform profiles ensures that each component fits perfectly in its intended application, which is vital in structural and architectural projects. This consistency also simplifies the assembly process, leading to faster construction times.

Applications in Various Industries

Due to their versatility, long span roll forming machines find applications across various industries. In the construction sector, they are commonly used to create roofing panels, wall cladding, and structural components. Their ability to produce lightweight yet robust materials makes them ideal for modern architectural designs.

In the automotive industry, roll forming is employed to manufacture various structural parts that require high strength-to-weight ratios. Given the continuous push for efficiency and fuel economy in automotive design, the lightweight properties of roll-formed components are highly coveted.

Conclusion

In summary, the long span roll forming machine represents a significant advancement in manufacturing technology. By enabling the efficient production of extended lengths of high-quality metal profiles, these machines are revolutionizing traditional manufacturing processes. From reducing material waste to increasing speed and precision, the advantages are compelling. As industries continue to evolve and demand greater efficiency and sustainability, long span roll forming machines will undoubtedly play a pivotal role in meeting these challenges head-on. The future of manufacturing is bright, and long span roll forming machines are at the forefront of that innovation.