Understanding Long Span Roll Forming Machines Revolutionizing Metal Fabrication

In the realm of metal fabrication, the long span roll forming machine has emerged as a game-changer for industries requiring large and consistent metal profiles. These machines are engineered to produce high-quality, continuous lengths of metal sections, which are critical for various applications, from construction to automotive components.

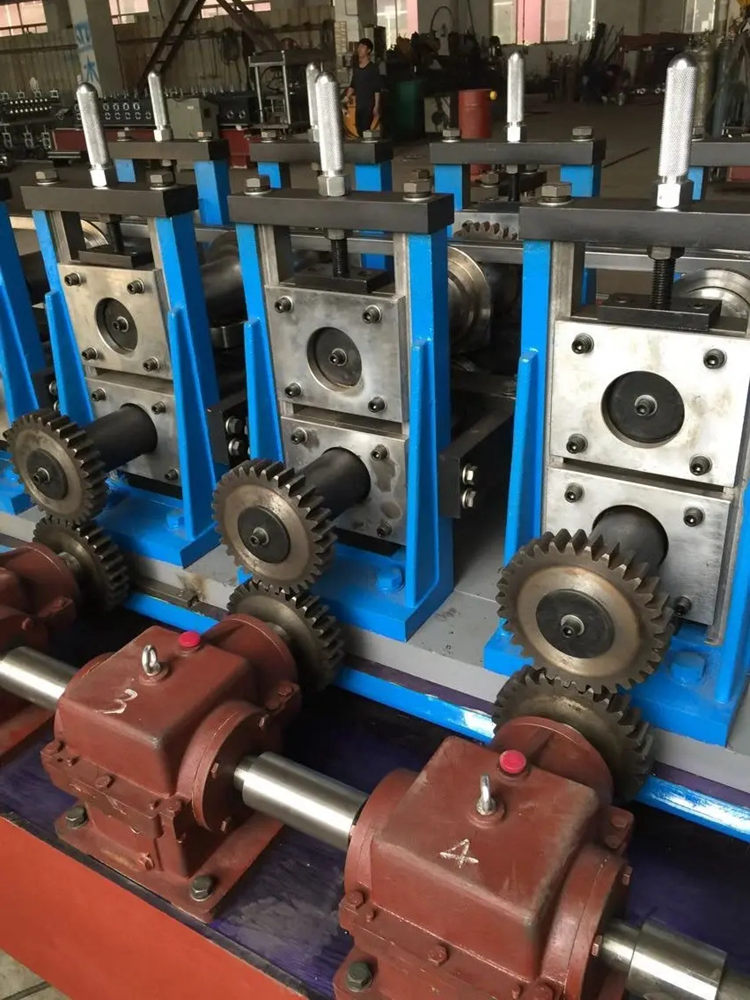

A long span roll forming machine operates by feeding metal sheets or strips through a series of rollers. As the material passes through these rollers, it is shaped into the desired profile, which could include roofing sheets, wall panels, or structural components. The process is highly efficient, allowing for the production of long lengths without the need for conventional cutting, significantly reducing material waste.

One of the key advantages of long span roll forming machines is their ability to produce products with exceptional dimensional accuracy and uniformity. The precise control over the forming process ensures that each profile meets stringent specifications, which is crucial in industries where reliability and safety are paramount. Moreover, this accuracy reduces the need for secondary operations, further streamlining the production line.

In addition to efficiency and accuracy, longevity and durability are inherent advantages of products produced by these machines. The continuous nature of roll forming results in stronger sections, as the material experiences less stress compared to other methods like stamping or cutting. This is particularly important in applications that demand high structural integrity, such as building frameworks and heavy-duty automotive parts.

Automation technology has also played a significant role in enhancing the capabilities of long span roll forming machines. Modern machines can be equipped with advanced controls that allow for real-time monitoring and adjustments, ensuring optimal performance across different production runs. This adaptability not only improves efficiency but also enables manufacturers to meet varying customer demands with ease.

As industries continue to evolve, the need for innovative and efficient manufacturing solutions grows. Long span roll forming machines are at the forefront of this evolution, offering unprecedented benefits in terms of production speed, efficiency, and product quality. They stand as a testament to the advancements in technology and engineering, showcasing how traditional processes can be transformed into modern solutions that meet the demands of today's fast-paced markets.

In conclusion, long span roll forming machines represent a vital advancement in metal fabrication technology. Their ability to produce high-quality, long-length profiles with precision and efficiency makes them indispensable in numerous applications. As manufacturers increasingly adopt these machines, we can expect to see continued improvements in product quality and operational efficiency across various industries.