Long Span Forming Machine for Steel Roofing Revolutionizing the Construction Industry

The construction industry has seen remarkable advancements in technology, and one of the most significant innovations is the long span forming machine for steel roofing. This state-of-the-art equipment is designed to enhance the efficiency and quality of metal roofing, providing numerous benefits to builders, architects, and construction companies alike.

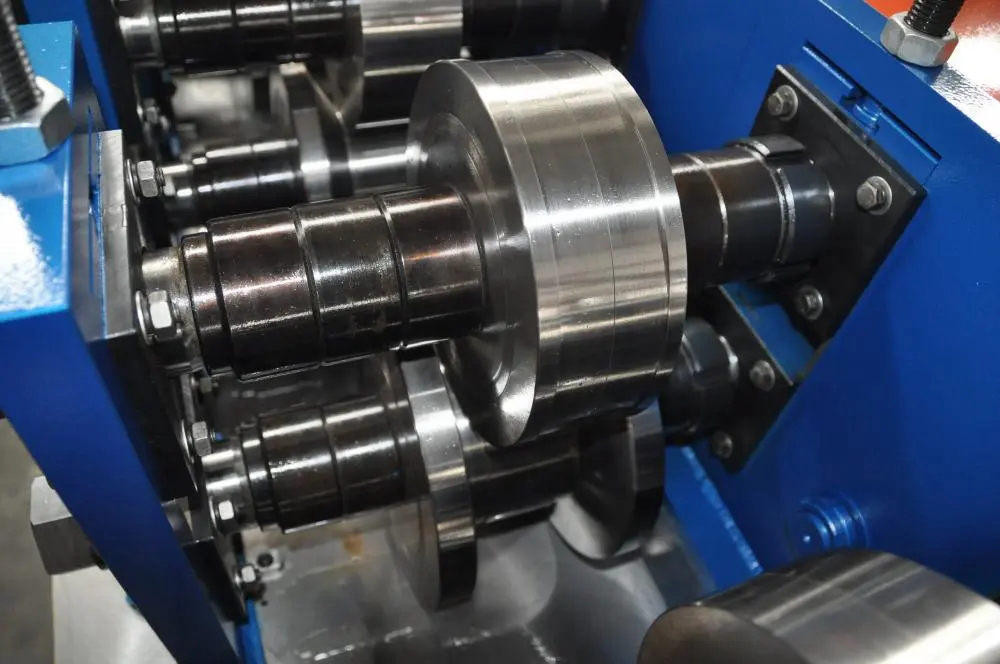

A long span forming machine is specialized equipment that fabricates metal sheets into specific profiles for roofing applications. Unlike traditional mechanical processes, these machines utilize advanced technology, including computer numerical control (CNC), to ensure precision and consistency in the formation of steel roofing panels. This technology has transformed the way roofing materials are produced, ensuring that they meet the stringent standards of modern architecture.

One of the primary advantages of using a long span forming machine is the ability to create longer roofing sheets

. Traditional roofing methods often involve the use of smaller panels that are joined together, leading to potential weaknesses at the seams and increased labor costs. In contrast, long span forming machines produce seamless sheets that can extend over long distances, reducing the number of joints and enhancing the overall structural integrity of the roof.Moreover, the use of longer panels allows for better water drainage and reduces the likelihood of leaks. This is especially crucial in regions prone to heavy rainfall and harsh weather conditions. By minimizing the seams, builders can create roofs that are not only aesthetically pleasing but also highly functional and durable.

Additionally, long span forming machines can accommodate a variety of steel materials, such as galvanized steel, aluminum, and other metal alloys. This versatility enables construction professionals to choose the best material for their specific project requirements, whether they are building commercial complexes, industrial facilities, or residential homes. The machine's ability to process different materials also opens up new design possibilities, allowing architects to be more creative with their roofing solutions.

Another significant benefit of long span forming machines is their impact on production efficiency. With automation and precision engineering, these machines can produce roofing panels at a much faster rate than traditional methods. This speed not only accelerates project timelines but also reduces labor costs. Construction crews can focus on installation rather than fabrication, facilitating faster project completion and increased profitability for contractors.

In addition to efficiency and speed, the quality of the finished product is greatly enhanced. Long span forming machines ensure uniformity in thickness and profile, which is vital for the overall performance of the roofing system. Consistent quality translates to fewer defects and a reduced likelihood of costly repairs in the future.

As sustainability becomes an increasingly important focus within the construction sector, long span forming machines also contribute positively to this initiative. By minimizing waste through efficient material usage and producing durable roofing solutions, these machines align with green building practices. Metal roofs are inherently recyclable, making them an environmentally friendly choice for builders looking to reduce their carbon footprint.

In conclusion, the long span forming machine for steel roofing represents a significant advancement in construction technology. Its ability to produce longer, high-quality, and efficient roofing solutions not only benefits builders but also enhances the durability and performance of roofing systems. As the construction industry continues to evolve, embracing such innovative technologies will be crucial for meeting the challenges of modern building demands.