Long Service Life Metal Stud Roll Forming Machine

In the modern construction industry, the efficiency and quality of building materials play a crucial role in determining the overall success of a project. Among the various materials utilized, metal studs have gained significant traction due to their durability, lightweight properties, and versatility in design. To capitalize on these advantages, manufacturers are increasingly turning to advanced technology such as the metal stud roll forming machine. This article explores the importance of long service life in metal stud roll forming machines and the aspects that contribute to their durability and performance.

Understanding Metal Stud Roll Forming Machines

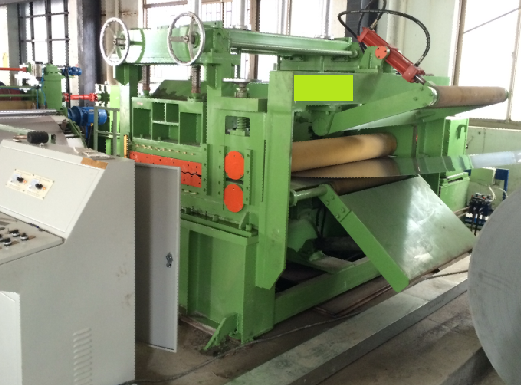

Metal stud roll forming machines are specialized equipment designed to produce metal studs in various sizes and configurations. The process involves unwinding metal coils, feeding them through various forming rollers, and then cutting them to the specified lengths. This method not only ensures consistency in the production of metal studs but also allows for rapid production rates, making it an ideal choice for construction projects with tight deadlines.

Importance of Long Service Life

The longevity of a metal stud roll forming machine is crucial for several reasons. Firstly, these machines represent a significant investment for manufacturing companies. A long service life means that the initial investment can be amortized over a longer period, resulting in lower overall production costs. In addition, machines with longer operational lifespans often require fewer repairs and replacements, which can also contribute to cost savings.

Furthermore, machines built for durability tend to maintain consistent production quality. Any wear and tear on the equipment can lead to fluctuations in the dimensions and tolerances of the metal studs produced, which can compromise the structural integrity of the final construction. Thus, a long-lasting machine ensures that the quality remains reliable over thousands of cycles.

Factors Contributing to Durability

1. Material Selection The materials used in the construction of the roll forming machine itself play a vital role in its service life. High-quality steel and other robust materials can withstand the rigorous demands of the forming process, which includes intense pressure and friction.

2. Design and Engineering A well-designed machine that includes features for reducing wear and ensuring easy maintenance can significantly extend its life. This includes considerations such as lubrication points, easy access for repairs, and components designed to reduce stress during operation.

3. Regular Maintenance Implementing a scheduled maintenance program can drastically extend the life of many machines, including metal stud roll forming machines. Routine inspections, lubrication, and timely replacement of wear parts can prevent unexpected breakdowns and prolong the machine's overall service life.

4. Technological Advancements Modern roll forming machines are incorporating cutting-edge technology that enhances efficiency and durability. Innovations such as programmable logic controllers (PLCs) and advanced computer systems can monitor machine performance and suggest when maintenance is required, thus keeping the machine in optimal condition.

Conclusion

The metal stud roll forming machine is an indispensable tool in the construction industry, known for its efficiency in producing high-quality metal studs. The long service life of these machines is paramount to maintaining production standards, reducing costs, and ensuring the reliability of construction projects. By focusing on factors such as material selection, design, maintenance, and technological advancements, manufacturers can enhance the durability of their metal stud roll forming machines. As the construction industry continues to evolve towards more sustainable and efficient practices, investing in high-quality, long-lasting machinery will remain a key strategy for success.