The realm of modern construction continually seeks advancements that can streamline the building process while ensuring durability and efficiency.

Light steel keel roll forming machines have emerged as an indispensable tool in this evolution, granting producers the ability to craft precise, robust structural components with ease. This article delves into why these machines are not just another piece of industrial equipment, but a cornerstone in contemporary construction practices.

For manufacturers and builders, the light steel keel roll forming machine is often celebrated for its versatility and efficiency. By automating the molding of light steel into uniform and precise shapes, these machines significantly reduce the time and labor traditionally required in manufacturing processes. This ability to produce high-quality components rapidly can substantially decrease project lead times, ultimately contributing to swifter completion of construction projects.

A key area where these machines shine is in their exceptional adaptability. With varying designs and configurations available, manufacturers can cater to an array of building requirements—ranging from residential to commercial designs. This flexibility is not only a testament to the machine's engineering expertise but also acts as a catalyst for innovation in structural design, permitting architects and builders to explore novel solutions without worrying about component fabrication constraints.

When discussing the construction industry, quality and precision are fundamental principles. The light steel keel roll forming machine excels in these areas by utilizing advanced technologies such as computer numerical control (CNC), ensuring each component meets specified dimensions down to the smallest detail. Such precision reduces the risk of errors in component dimensions, ensuring a snug fit during assembly and minimizing wastage of materials—a quality that resonates well with principles of sustainable construction.

Furthermore, the durability of components produced by light steel keel roll forming machines cannot be overstated. Light steel, known for its high strength-to-weight ratio, provides an ideal material that aligns perfectly with the needs of modern lightweight construction methodologies without compromising on structural integrity. The roll forming process itself enhances this strength by working the steel through progressive stages, incrementally increasing its tensile strength, which ultimately results in a finished product capable of withstanding substantial weight and environmental stressors.

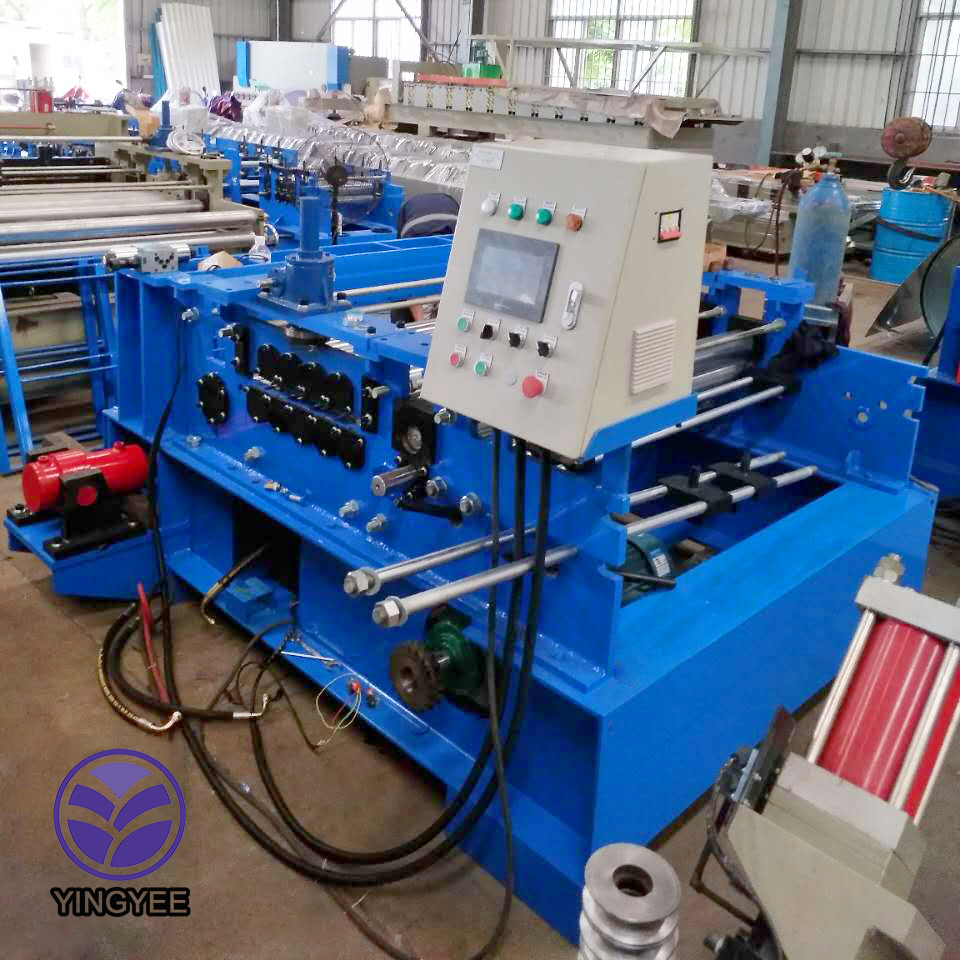

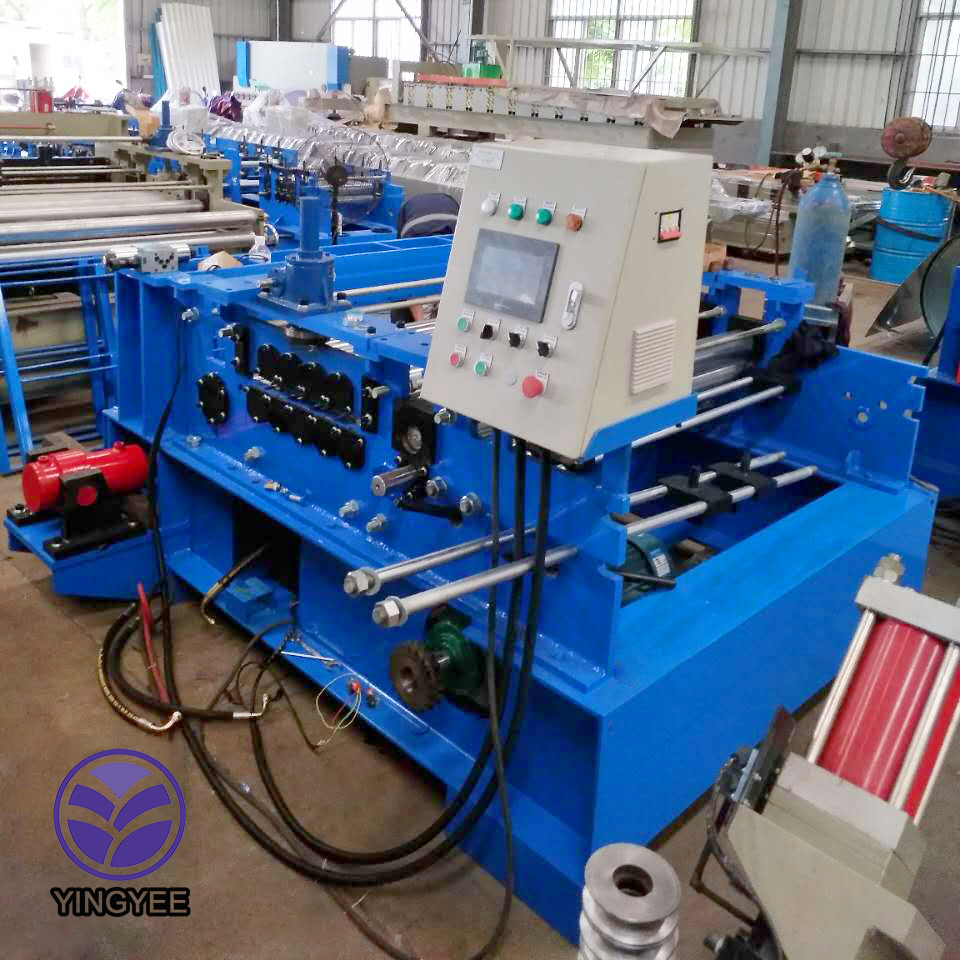

light steel keel roll forming machine

From an operational standpoint, these machines are designed with user-friendliness and efficiency in mind. Training operators to use the machines can be achieved relatively quickly, thus expanding the workforce that can confidently produce structural components. Moreover, their energy-efficient operation minimizes electricity consumption, making them a cost-effective choice over alternative methods that require more manpower and energy.

Given these numerous advantages, the role of light steel keel roll forming machines transcends mere industrial utility—they are a testament to production efficacy and technological progress. As discussions about sustainable and efficient building practices intensify, these machines offer a practical pathway towards achieving these goals. Their contribution to reducing manual labor, enhancing product quality, and supporting sustainable practices reinforces their status as an authoritative solution in the industry.

In a sector that is continuously pushed towards innovation due to economic pressures and regulatory demands, the role of expert evaluation and hands-on experience cannot be overlooked. Companies investing in these machines can benefit significantly from consultations with seasoned professionals to tailor their production lines for peak efficiency. This collaboration enhances trustworthiness in product outputs, ensuring that the components not only meet market expectations but excel them.

Ultimately, adopting light steel keel roll forming machines reinforces a company’s commitment to high standards in production while securing a competitive edge in the marketplace. Firms that leverage this technology exhibit a robust combination of expertise, authority, and reliability, qualities highly valued by clients and pivotal for sustained success.