When it comes to investing in a light keel roll forming machine factory, understanding the intricacies of production, technology, and market demands is paramount for ensuring successful operations. Having spent over a decade in the steel framing industry, I've witnessed firsthand the evolution and growth of roll forming technology and how a strategically run factory can dominate the market.

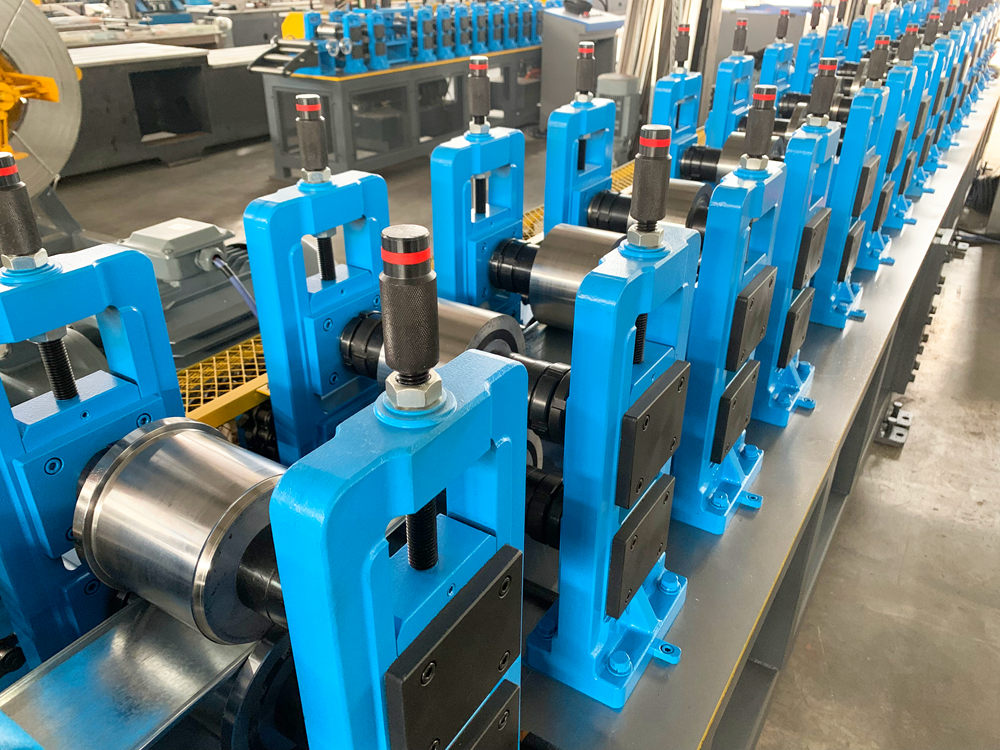

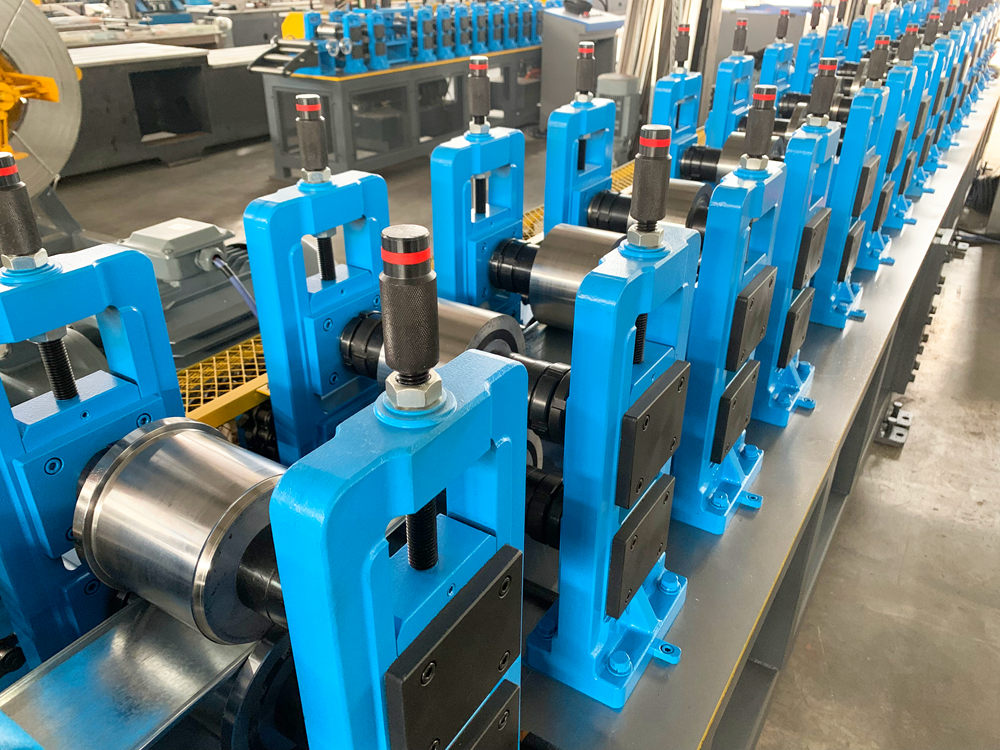

Light keel roll forming machines are essential for producing the lightweight, durable, and precise steel components used in construction, particularly in interior frameworks. These machines have revolutionized how construction material is produced, offering unparalleled efficiency and consistency. The quality of the end product depends heavily on the technology and processes employed within the factory, making expertise in this area invaluable.

To establish a competitive factory,

understanding the latest in roll forming technology is crucial. The machines have evolved to incorporate advanced automation and precision control systems that reduce human error and labor costs. Factories leveraging these modern advancements are able to produce higher volumes of superior-quality steel profiles, meeting even the most stringent industry standards. Investment in top-tier production lines, equipped with state-of-the-art roll forming technology, is not just an option but a necessity for any aspiring factory owner or operator looking to lead in this field.

Furthermore, operating a light keel roll forming machine factory requires a deep understanding of engineering and material science. The expertise involved in calibrating and maintaining these machines cannot be overstated. Factories should employ engineers who are not only trained in the operational aspects of these machines but who also possess a robust understanding of steel material properties and behavior under different conditions. This technical know-how is crucial in adjusting machine settings to accommodate different steel compositions, thicknesses, and the unique demands of specific construction projects.

True authority in this industry is marked by a factory's commitment to innovation and quality. By integrating real-time data analytics into production processes, factories can optimize efficiency and predict maintenance needs, thereby reducing downtime and ensuring consistent output quality. Additionally, certifications from recognized industry bodies serve as testimonies to a factory's commitment to excellence and adherence to international production standards. Such credentials not only enhance a factory's market reputation but also instill trust among clients who know they are receiving a product that meets their exact specifications and regulatory requirements.

light keel roll forming machine factory

Trustworthiness is the backbone of any successful manufacturing business. In a light keel roll forming machine factory, it begins with transparent business practices. Offering potential clients tours of the factory premises, showcasing the production process, and presenting data on production efficiency and quality control measures all contribute to building trust. Particularly in international markets, where clients cannot always physically visit, maintaining transparent digital communication lines and customer service channels is crucial.

Moreover, building long-term relationships with material suppliers ensures consistent quality and price stability, which is essential in offering competitive pricing to clients. Partnering with suppliers who also prioritize sustainability can add an edge for factories as industries worldwide increasingly seek eco-friendly construction solutions.

Lastly, an often overlooked aspect is the importance of training and skill development within the workforce. A well-trained team not only ensures smooth operations but also contributes innovative ideas for process improvements, thereby enhancing overall productivity and product quality. Establishing continuous training programs and workshops can uplift a factory's workforce, creating an environment where expertise in using light keel roll forming technology can flourish.

In conclusion, running a successful light keel roll forming machine factory is less about the machinery itself and more about the synergy between cutting-edge technology, skilled personnel, transparent practices, and strong supplier relationships. These elements combined build a foundation of expertise, authority, and trustworthiness, necessary to thrive in this competitive industry landscape.