The Light Keel Roll Forming Machine Revolutionizing Steel Fabrication

In the realm of modern construction and manufacturing, the efficiency and precision of metal fabrication play crucial roles. Among the myriad of machines designed for this purpose, the light keel roll forming machine stands out for its innovative approach and remarkable capabilities. This machine specializes in the production of lightweight steel keels, which are essential components in the construction of various structures, particularly in the framing of buildings.

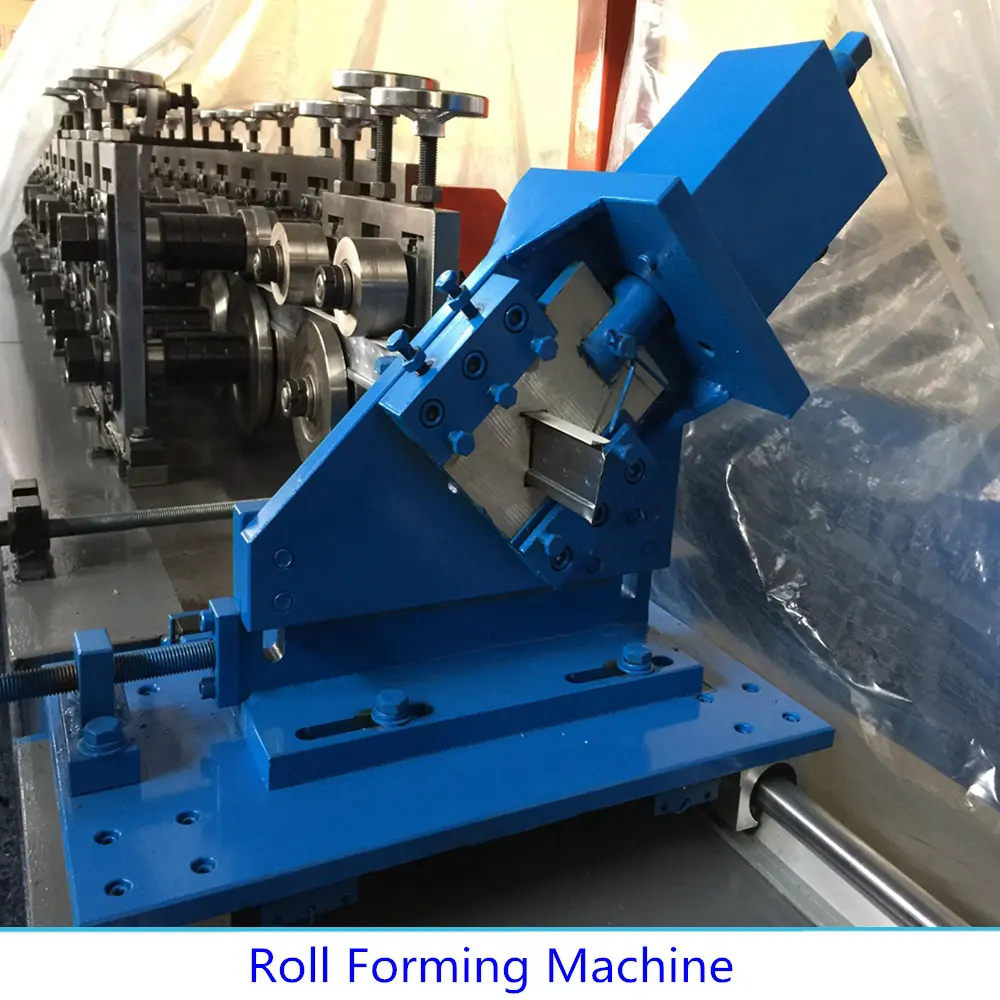

The process begins with the feeding of metal sheets, typically cold-rolled steel, into the machine. As the sheets pass through a series of precisely arranged rollers, they undergo continuous shaping, transforming flat metal into uniformly rolled profiles. This continuous roll forming process is not only fast but also minimizes material waste, making it an environmentally friendly choice for manufacturers.

One of the key advantages of the light keel roll forming machine is its ability to produce keels of various shapes and sizes, catering to the specific needs of different construction projects. From residential buildings to larger commercial structures, these machines can be adjusted to create profiles that meet unique engineering specifications. This flexibility is crucial in an industry where customization is often necessary for optimal structural integrity.

Moreover, the lightweight nature of the steel keels produced by these machines provides numerous benefits. Firstly, they significantly reduce the overall weight of the framework, easing transportation and installation processes. This is crucial in urban areas where accessibility can be a challenge. Secondly, lighter structures can lead to lower foundation costs, providing a substantial economic advantage in large-scale construction projects.

Another aspect worth noting is the reliability and durability of the products manufactured by the light keel roll forming machine. The steel used is often treated to resist corrosion and wear, extending the lifespan of the keels and ensuring that they maintain structural integrity over time. This durability is especially vital in areas prone to extreme weather conditions.

In addition to the mechanical advantages, these machines also promote efficiency in production. Many models are equipped with advanced automation technologies, allowing for the quick and precise operation of the roll forming process. This not only accelerates production rates but also enhances consistency, ensuring that each keel produced meets stringent quality standards.

In conclusion, the light keel roll forming machine represents a significant advancement in the field of metal fabrication. By combining efficiency, customization, and durability, these machines are redefining how steel keels are produced, ultimately contributing to the more sustainable and economical construction of our modern environments. As industries continue to seek improved manufacturing solutions, the evolution of such specialized machinery will undoubtedly play a pivotal role in shaping the future of construction.