The Advantages of Light Keel Roll Forming Machines

In the construction and manufacturing industries, efficiency and precision are paramount. One of the most innovative tools that has emerged to meet these demands is the light keel roll forming machine. This advanced machinery is designed specifically for producing lightweight metal keels used in various applications, particularly in the construction of interior walls and ceilings.

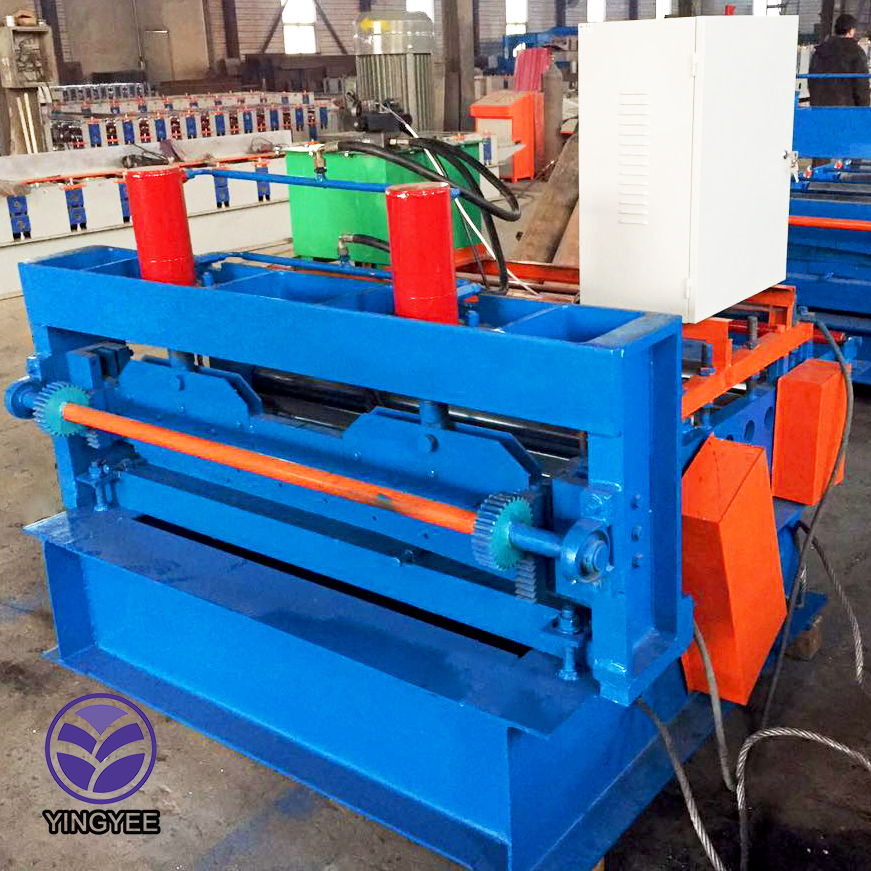

The primary advantage of using a light keel roll forming machine is its ability to produce high-quality, uniform profiles with minimal waste. These machines operate using a continuous metal strip that is fed through a series of rollers. As the strip passes through, it is shaped into desired profiles, effectively reducing production times compared to traditional methods. This efficiency not only speeds up manufacturing processes but also lowers costs, making it an attractive option for businesses looking to maximize profits while maintaining high standards.

One of the standout features of light keel roll forming machines is their versatility. They can be adjusted to create various keel types and sizes to accommodate different construction needs. This adaptability allows manufacturers to respond quickly to changing market demands without needing extensive retooling or significant downtime. This flexibility is particularly beneficial in times when custom solutions are required, ensuring that businesses can meet client specifications precisely.

Moreover, these machines are often designed with automation in mind, which enhances their usability and increases production consistency. Automated systems can monitor the forming process, ensuring that each piece meets exact specifications, thereby reducing the risk of human error. This automation not only increases productivity but also minimizes material waste, further enhancing overall efficiency.

Light keel roll forming machines also contribute to sustainability in construction. By optimizing material use and producing components that are lightweight yet robust, these machines help reduce the overall environmental impact of construction projects. Lighter materials require less energy for transportation, and their efficient design can lead to reduced energy consumption during the building process.

In conclusion, light keel roll forming machines represent a significant advancement in manufacturing technology, particularly in the construction sector. Their ability to produce high-quality, custom profiles efficiently, coupled with their versatility and sustainability benefits, makes them an invaluable asset for modern manufacturing businesses. As the demand for innovative building solutions continues to grow, the role of light keel roll forming machines is expected to become even more critical in shaping the future of construction.