The Advantages of Light Gauge Steel Roll Forming Machines

In the realm of construction and architecture, the use of light gauge steel has gained significant popularity due to its versatility, durability, and economic advantages. Light gauge steel roll forming machines play a pivotal role in the production of steel components that are essential for modern building designs. These machines offer a range of benefits that make them invaluable in the construction industry.

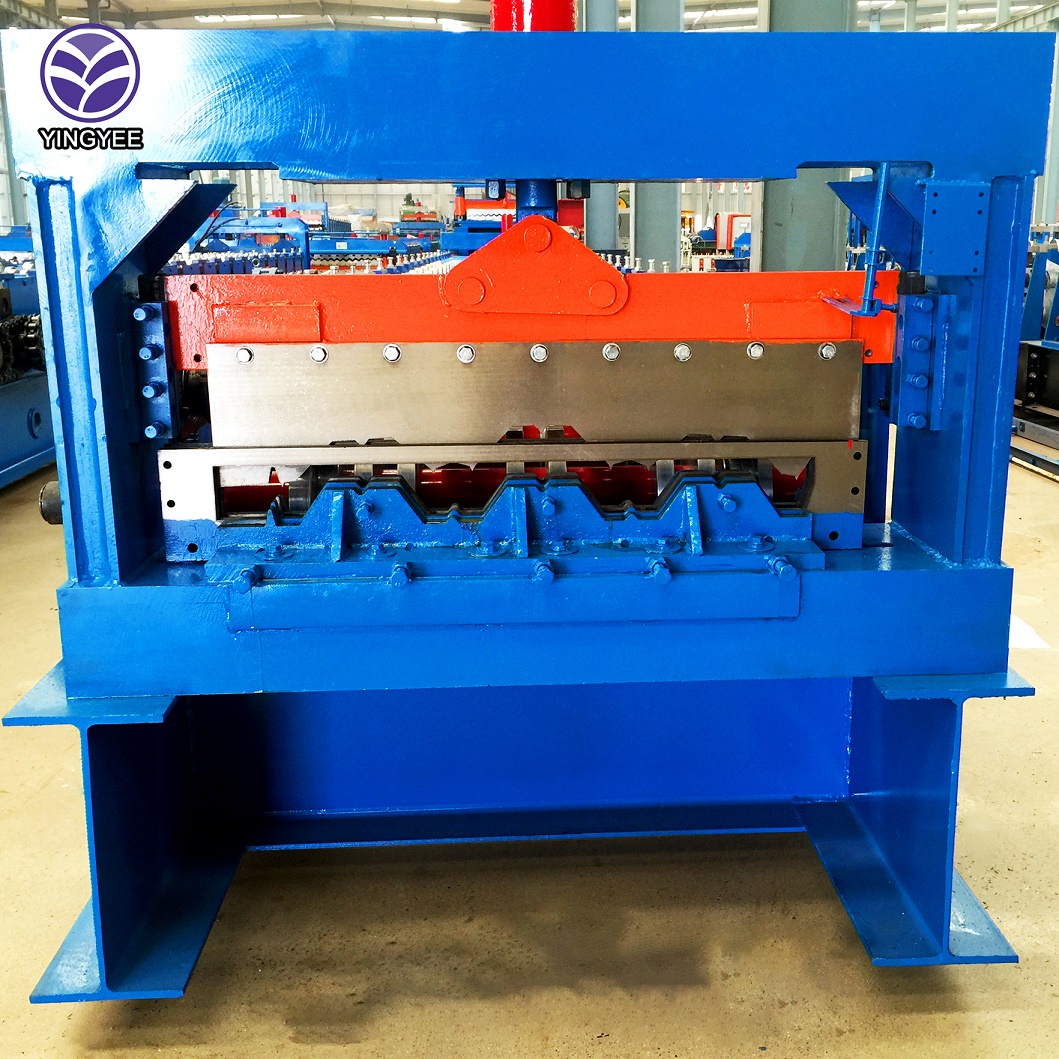

Light gauge steel, typically defined as steel with a thickness of less than 3mm, is favored for its lightweight yet robust properties. It provides an excellent alternative to traditional materials like wood or concrete. Roll forming machines specialize in taking flat steel coils and gradually shaping them into desired profiles as they pass through a series of rollers. This continuous forming process ensures uniformity and precision in the end products, which commonly include studs, tracks, and various structural components for walls, roofs, and ceilings.

One of the primary advantages of using a light gauge steel roll forming machine is the efficiency it brings to manufacturing. These machines operate at high speeds, significantly reducing the time required to produce steel components. The automation involved not only speeds up the production process but also minimizes human error, leading to higher-quality products. This efficiency translates to cost savings, making it a lucrative option for contractors and builders looking to optimize their budgets.

Furthermore, light gauge steel components are lightweight, allowing for easier handling and transportation. This characteristic is particularly beneficial in locations where heavy machinery may be restricted or in urban areas with limited access. The reduced weight also contributes to lower shipping costs and can lead to savings in structural support requirements, resulting in lower overall project costs.

Sustainability is another critical aspect of light gauge steel usage. Steel is 100% recyclable, and its production can often be completed with a lower carbon footprint compared to other materials. Using light gauge steel in construction projects aligns with modern sustainability goals, as it significantly minimizes waste and promotes the use of recycled materials. This aspect is increasingly important in today's environmentally conscious market.

Moreover, light gauge steel roll forming machines are highly customizable. Manufacturers can create special profiles tailored to specific project needs, which is a significant advantage over traditional steel production methods. This flexibility enables builders and architects to implement innovative designs without the usual constraints associated with conventional materials.

In conclusion, light gauge steel roll forming machines are essential tools in the contemporary construction industry. They enhance efficiency, reduce costs, and support sustainability while providing customization options for innovative designs. As the demand for light gauge steel continues to rise, investing in advanced roll forming technology offers a competitive edge for manufacturers and builders alike, paving the way for a more efficient and environmentally friendly construction process. As this technology evolves, it will undoubtedly shape the future of building materials, reinforcing the importance of light gauge steel in modern construction practices.