Understanding Light Gauge Steel Framing Machines

Light gauge steel framing machines play a pivotal role in modern construction, particularly in the building of residential and commercial structures. These machines facilitate the manufacturing of light gauge steel (LGS) components, which are essential in creating strong, lightweight, and durable frameworks. This article explores the significance, benefits, and operational aspects of light gauge steel framing machines.

What is Light Gauge Steel?

Light gauge steel is a construction material made from thin sheets of steel that are processed and shaped into various forms to create structural components. These components, including studs, tracks, and joists, are used in framing walls, roofs, and floors. The lightweight nature of these materials simplifies transportation and assembly while maintaining structural integrity.

The Role of Light Gauge Steel Framing Machines

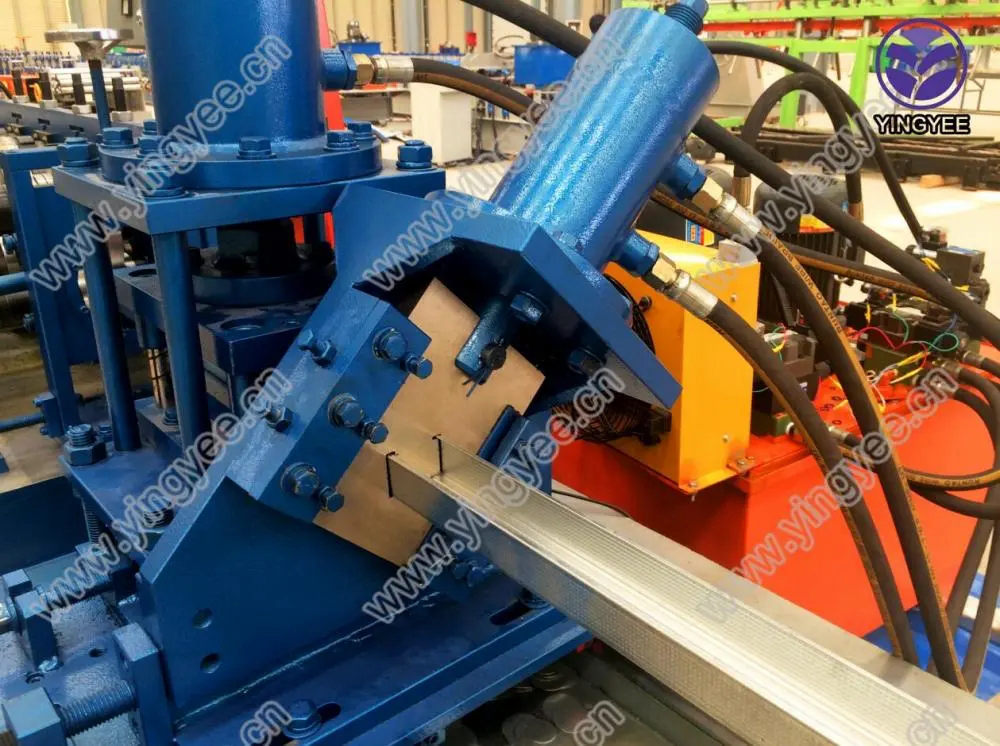

Light gauge steel framing machines automate the process of producing LGS components. These machines are equipped with advanced technologies such as computerized controls and automated cutting and forming capabilities. This enhances precision and efficiency, allowing manufacturers to produce consistent and high-quality steel components in a shorter amount of time.

Key Benefits of Using Light Gauge Steel Framing Machines

1. Efficiency and Speed One of the primary advantages of employing light gauge steel framing machines is the speed at which they operate. Traditional framing methods can be time-consuming, whereas these machines can produce a large volume of components swiftly. This drastically reduces construction timelines and helps projects stay on schedule.

2. Cost-Effectiveness Although the initial investment in a light gauge steel framing machine may be significant, the long-term savings are substantial. The efficiency of these machines leads to lower labor costs and reduced material waste. Additionally, the durability of steel reduces the need for repairs and maintenance down the line.

3. Precision and Consistency Manual framing can lead to variations in size and quality. A light gauge steel framing machine ensures that every component is produced to exact specifications, which is crucial for the structural integrity of the building. This uniformity helps avoid costly adjustments during the construction process.

4. Sustainability Steel is a recyclable material, and using LGS helps promote sustainable building practices. With light gauge steel framing machines, manufacturers can utilize scrap steel and reduce overall waste, contributing to environmentally friendly construction.

5. Versatility Light gauge steel framing machines can be adapted to produce a variety of shapes and sizes, making them suitable for different construction needs. Whether for residential homes, commercial buildings, or industrial structures, these machines can accommodate diverse architectural designs.

Operational Aspects

Operating a light gauge steel framing machine requires skilled personnel who understand both the technology and the nature of steel work. These machines often come with comprehensive software that allows operators to program the desired specifications. Regular maintenance is also crucial to ensure optimal performance and prevent downtime.

In addition to the machines themselves, a robust supply chain for steel and a streamlined process for transporting finished components to construction sites are essential for maximizing efficiency. Training programs for operators can enhance skills and ensure safety standards are met in the work environment.

Conclusion

Light gauge steel framing machines represent a significant innovation in the construction industry. By combining speed, efficiency, precision, and sustainability, they address many challenges faced by traditional construction methods. As the demand for quality and timely construction continues to grow, investing in these machines will likely yield substantial benefits for businesses and the construction landscape as a whole. As the industry evolves, the role of light gauge steel framing machines will become increasingly critical to achieving modern building standards and meeting the needs of a rapidly developing world.