Large Span Roll Forming Machine Revolutionizing Metal Fabrication

In the ever-evolving landscape of manufacturing, efficiency and precision have become paramount. One of the standout innovations in metal fabrication technology is the large span roll forming machine. This sophisticated machinery is designed to create long, continuous metal sections with varying cross-sectional profiles, catering to diverse industrial applications such as construction, automotive, and specialized manufacturing.

Understanding Roll Forming

Roll forming is a continuous bending process in which a long strip of metal is passed through a series of rollers to progressively form it into desired shapes. This method is ideal for producing parts with uniform cross-sections, allowing for enhanced strength and reduced weight—qualities that are increasingly valued in modern engineering and construction. Traditional roll forming machines worked well for smaller components, but with the growing demand for larger spans—such as those required for roofing, wall panels, and structural components—the large span roll forming machine has emerged as a game changer.

Design and Functionality

Large span roll forming machines are characterized by their ability to handle longer lengths of materials, often exceeding several meters, without compromising on the precision of the formed profiles

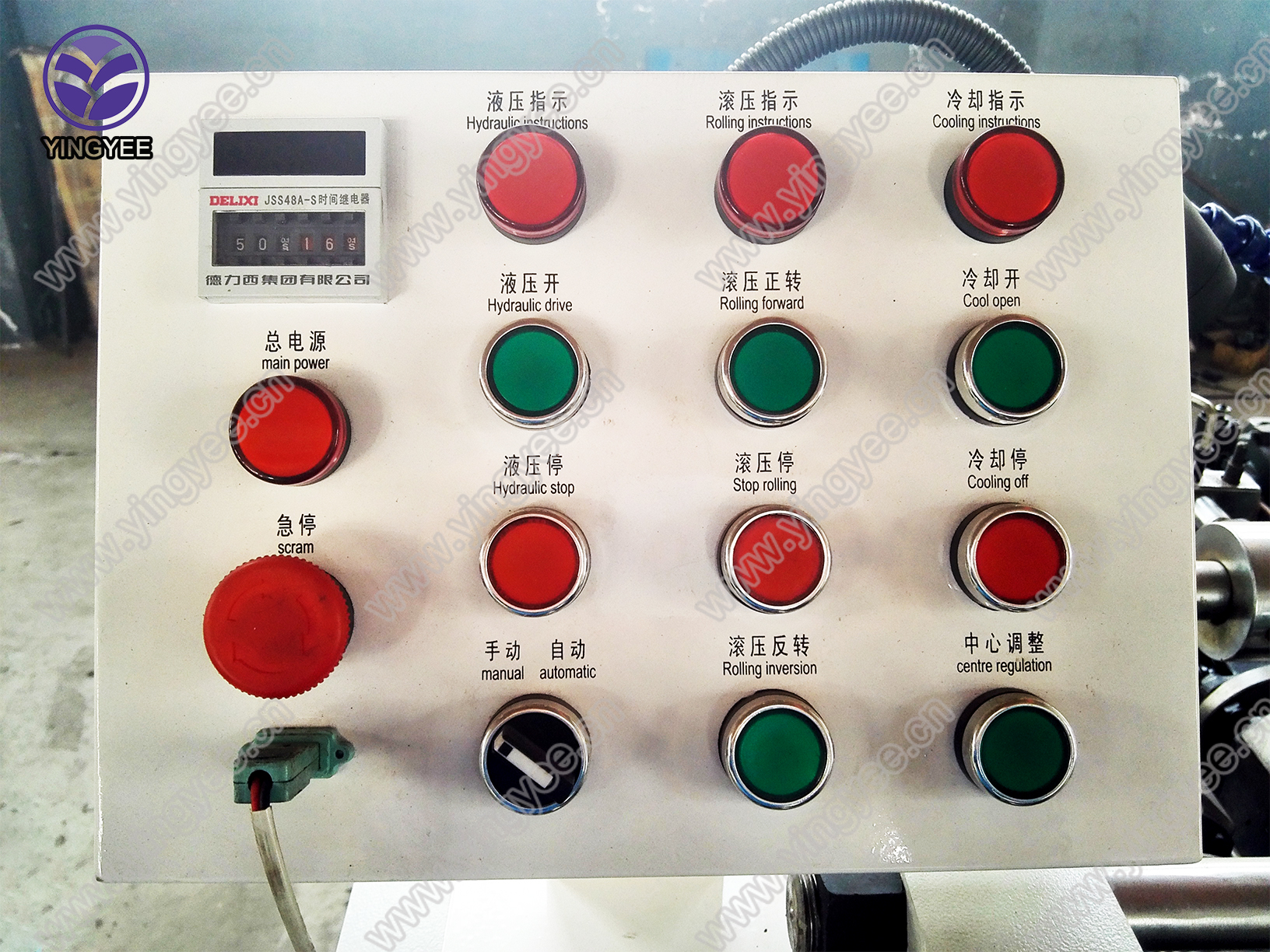

. The design of these machines typically incorporates multiple roller stations, each meticulously engineered to achieve specific bend angles and dimensions.These machines often include advanced technologies such as programmable logic controllers (PLCs) and touch-screen interfaces, which simplify the operation and enhance accuracy. Automation plays a crucial role in these machines, allowing for quick adjustments between different product specifications and reducing downtime. Furthermore, the incorporation of sensors ensures that any deviations in the metal strip’s properties can be immediately addressed, maintaining the highest standards of product quality.

Applications

The versatility of large span roll forming machines makes them suitable for a wide range of applications. In the construction industry, they are extensively used to fabricate roof trusses, wall panels, and channel sections that are essential for structural integrity. The automotive sector benefits from these machines by producing lightweight yet strong components that contribute to fuel efficiency and safety.

Moreover, large span roll forming machines are also instrumental in the production of HVAC ducting systems, where the seamless transition between different sections can significantly enhance airflow efficiency. With customization options available, manufacturers can develop unique profiles tailored to specific project requirements, further expanding the utility of these machines.

Economic Advantages

Investing in a large span roll forming machine can yield substantial economic benefits. The reduced material waste minimizes production costs, while the speed and efficiency of the machines contribute to lower labor expenses. Furthermore, the durability and strength of the formed products often lead to decreased maintenance costs and extended product lifespans, providing additional return on investment.

Conclusion

The large span roll forming machine represents a significant advancement in metal fabrication technology. With its ability to produce high-quality, precision-engineered components on an industrial scale, it meets the demands of various sectors while driving efficiency and reducing costs. As industries continue to seek innovative solutions that promote sustainability and productivity, the role of large span roll forming machines will only become more crucial. As manufacturers embrace this technology, they will not only enhance their competitive edge but also contribute to the evolution of modern engineering practices.