Large Span Roll Forming Machine Revolutionizing the Manufacturing Industry

In the realm of modern manufacturing, efficiency and precision are paramount. With a continuous demand for high-quality metal components across various industries, the large span roll forming machine has emerged as a cutting-edge solution for producing long, intricate metal profiles. This technology not only enhances productivity but also reduces waste, making it an indispensable asset for manufacturers worldwide.

Understanding Roll Forming Technology

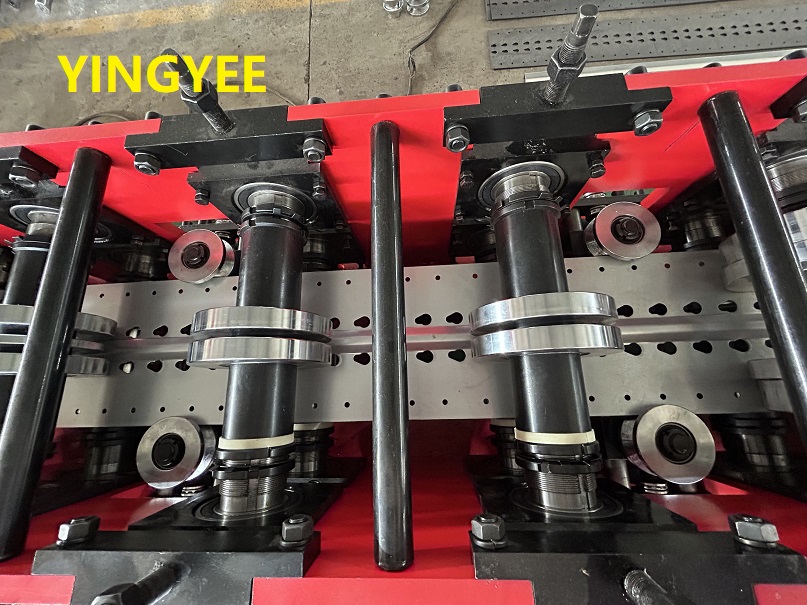

Roll forming is a continuous bending process in which metal strips or sheets are shaped into desired cross-sections by passing through a series of rollers. Unlike traditional methods, roll forming offers greater flexibility in design and higher production speeds. The large span roll forming machine is specifically designed to handle broader sheets of metal, enabling manufacturers to create larger and more complex profiles than ever before.

Key Features and Advantages

1. High Efficiency Large span roll forming machines are engineered for high-speed production. They can produce long sections of metal profiles in a fraction of the time that traditional methods require. This efficiency translates into significant cost savings and improved turnaround times, making it an attractive option for companies looking to enhance their operational capabilities.

2. Versatility One of the standout features of large span roll forming machines is their versatility. They can accommodate various materials, including steel, aluminum, and copper, and are capable of producing a wide range of profiles for different applications—ranging from construction and automotive to appliances and furniture.

3. Precision and Consistency The advanced technology utilized in these machines ensures that the profiles produced are of uniform quality and dimensional accuracy. This is critical in industries where specifications are stringent, as it reduces the likelihood of defects and rework, thus optimizing the overall manufacturing process.

4. Reduced Waste Roll forming minimizes material waste by taking advantage of the entire strip of metal. Unlike other fabrication methods, which may generate scrap during cutting or shaping, roll forming efficiently uses raw materials, resulting in a more sustainable manufacturing approach.

5. Automation and Integration Many large span roll forming machines come equipped with automated controls and integration capabilities for upstream and downstream processes. This allows for seamless transitions between different stages of production, reducing manual labor requirements and increasing overall productivity.

Applications in Various Industries

The applicability of large span roll forming machines spans numerous sectors. In construction, they are used to produce roofing sheets, wall panels, and structural components, providing durability and aesthetic appeal. In the automotive industry, these machines manufacture parts that are essential for vehicle assembly, like reinforcements and trim. Additionally, the appliance industry utilizes roll forming to create components such as brackets and frames, showcasing the technology's adaptability.

Challenges and Future Prospects

While large span roll forming machines present incredible opportunities, manufacturers must also navigate several challenges. The initial investment costs can be high, and companies need to invest in training for operators to maximize the machine's potential. However, as technology advances and production processes evolve, these machines are becoming increasingly cost-effective.

Looking ahead, the future of large span roll forming machines is promising. Innovations in automation and smart technology, such as IoT integration and machine learning, will further enhance their efficiency and adaptability. As manufacturers continue to prioritize sustainability and efficiency, the adoption of roll forming technology is expected to grow.

Conclusion

In conclusion, the large span roll forming machine is a game-changer in the manufacturing landscape. Its ability to produce high-quality, precise, and complex metal profiles at high speeds positions it as a crucial tool for a wide array of industries. As manufacturers embrace this advanced technology, they will not only enhance productivity but also contribute to a more sustainable and efficient future in manufacturing.