The Large Span Forming Machine Revolutionizing Construction and Manufacturing Industries

In the rapidly evolving realms of construction and manufacturing, efficiency and precision are paramount. One of the remarkable innovations addressing these demands is the Large Span Forming Machine (LSFM). This sophisticated piece of equipment is designed to facilitate the fabrication of large and complex structures, whether in the construction of buildings, bridges, or specialized industrial components. The LSFM not only enhances production capabilities but also introduces several benefits that redefine industry standards.

What is a Large Span Forming Machine?

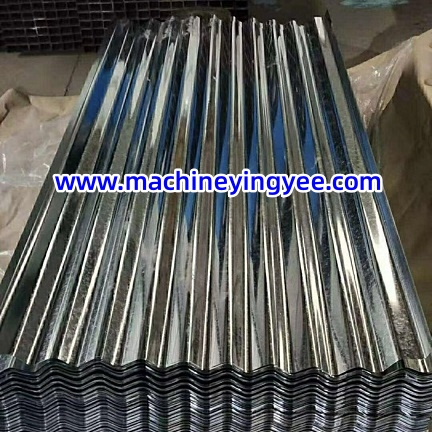

A Large Span Forming Machine is a specialized industrial tool designed to shape and manufacture large span structures from various materials, predominantly metals and composites. These machines employ advanced forming techniques that allow for significant manipulation of materials, including bending, twisting, and molding, to achieve desired geometries. With the ability to handle larger dimensions than traditional machines, LSFM significantly broadens the scope of projects that industries can undertake.

Typically featuring a computer-aided design (CAD) interface, these machines enable engineers to create intricate designs and specifications digitally. The precision offered by LSFM ensures that every piece produced meets stringent quality standards, reducing the need for reworks and adjustments. This not only saves time but also cuts down on material waste — a critical consideration in modern manufacturing practices.

The Applications of LSFM

Large Span Forming Machines find their applications across various sectors. In the construction industry, LSFM is pivotal in fabricating structural components such as beams, trusses, and frames, which are essential for erecting large buildings and infrastructures like bridges and stadiums. The ability to create components that can span great distances without the need for excessive support structures contributes significantly to architectural designs that prioritize aesthetics and functionality.

In the aerospace sector, LSFM plays a crucial role in manufacturing components for aircraft and spacecraft, where precision and material integrity are essential. The complex shapes required in aerospace designs can be efficiently produced with LSFM, ensuring the aircraft's performance and safety.

The automotive industry also benefits from LSFM technology, particularly in the production of lightweight and durable parts. As the demand for electric and hybrid vehicles grows, manufacturers are increasingly utilizing advanced materials that require specialized forming techniques, making LSFM indispensable.

Advantages of Large Span Forming Machines

The benefits of adopting LSFM technology are manifold. Firstly, the efficiency of production is significantly enhanced. LSFM allows for high-volume production runs with minimal downtime, which is crucial for meeting large-scale project demands. Secondly, the precision offered by these machines reduces errors during production, which translates to lower costs in terms of labor and materials.

Moreover, LSFM enhances design flexibility. Engineers and designers can experiment with different materials and structures without the limitations imposed by conventional manufacturing processes. This adaptability leads to innovative designs that can meet contemporary challenges, such as sustainability and energy efficiency.

Challenges and Future Directions

Despite the numerous advantages, the implementation of Large Span Forming Machines is not without challenges. High initial costs and the need for specialized training to operate these machines can pose barriers for smaller manufacturers. Additionally, ongoing maintenance and technical support are critical to ensure optimal performance.

As technology continues to advance, the future of LSFM looks promising. Innovations in automation and artificial intelligence are expected to enhance machine capabilities, providing greater flexibility and efficiency. Moreover, the integration of Internet of Things (IoT) technology will facilitate real-time monitoring and predictive maintenance, further optimizing production processes.

Conclusion

The Large Span Forming Machine stands at the forefront of modern manufacturing and construction technology. By enabling the production of large, complex structures with high precision and efficiency, LSFM is revolutionizing various industries. As technology advances, the potential for LSFM to drive innovation and sustainability in construction and manufacturing will only increase, ensuring its vital role in shaping the future of these sectors.