Large Span Forming Machines Revolutionizing Manufacturing

In the ever-evolving landscape of manufacturing, the development of advanced technologies has paved the way for increased efficiency and precision. Among these innovations, large span forming machines (LSFMs) stand out as a pivotal tool in the production process. These machines, designed for the creation of large and complex components, offer unmatched capabilities that cater to various industries including aerospace, automotive, construction, and shipbuilding.

What Are Large Span Forming Machines?

Large span forming machines are specialized equipment that can shape and manipulate metals and other materials into larger components than traditional forming machines. Typically, they are equipped with a robust framework that supports extensive spans, allowing for the fabrication of parts that can reach several meters in length. This capability is instrumental in industries where large components are commonplace, such as in the creation of aircraft wings, large structural beams for buildings, or components for wind turbines.

Key Features and Functions

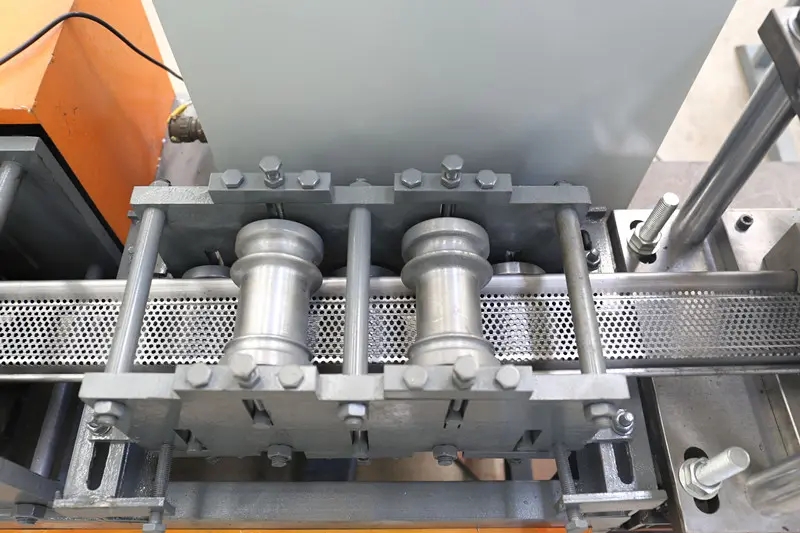

The design of LSFMs incorporates various advanced technologies that enhance their performance. One of the critical characteristics is the ability to perform multiple forming processes, including bending, stretching, and coiling, in a single setup. This reduces production time and minimizes the need for multiple machines. Additionally, many LSFMs feature programmable controls that allow for high levels of automation, improving precision and repeatability in the manufacturing process.

Another significant feature of large span forming machines is their ability to handle diverse materials. They are capable of forming various types of metals such as aluminum, steel, and titanium, as well as composite materials, making them versatile tools for manufacturers. The ability to customize forming parameters according to the specific material characteristics ensures optimal results, further enhancing the efficiency of production.

Benefits of Using LSFMs

The advantages of employing large span forming machines in manufacturing processes are manifold. Firstly, their capacity to form large components in a single operation leads to significant time savings. This efficiency translates to reduced labor costs and faster turnaround times, enabling manufacturers to respond quickly to market demands.

Secondly, the precision offered by LSFMs results in higher-quality products. With advanced measurement and control systems, manufacturers can achieve tighter tolerances and superior surface finishes, which are critical in industries where safety and reliability are paramount, such as aerospace.

Moreover, the automation features of LSFMs reduce the likelihood of human error, ensuring consistency across production batches. This consistency not only enhances product quality but also simplifies the quality control process, allowing manufacturers to maintain high standards throughout their operations.

Applications Across Industries

Large span forming machines find applications in numerous fields. In the aerospace industry, they are utilized for the production of wings, fuselage sections, and other critical components, where precision and weight reduction are essential. The automotive sector employs these machines to create frames and body panels, optimizing material usage and enhancing the vehicle's performance.

In construction, LSFMs play a vital role in producing large structural elements like beams and columns, which are crucial for modern architectural designs. Similarly, the wind energy sector benefits from LSFMs for manufacturing large turbine blades, contributing to the push for sustainable energy solutions.

Conclusion

As manufacturers continue to seek innovative ways to enhance productivity and product quality, large span forming machines serve as a critical element in achieving these goals. Their ability to handle large components with precision and efficiency makes them indispensable in various industries. With ongoing advancements in technology, the capabilities of LSFMs are expected to expand, further revolutionizing the manufacturing landscape and fostering greater innovation across sectors. As we move forward, embracing these machines will undoubtedly reshape the future of large-scale production, helping industries meet the challenges of a rapidly changing world.