Lace Door Frame Roll Forming Machine Revolutionizing Modern Manufacturing

In the realm of modern manufacturing, technological advancements continue to reshape industries and improve efficiency. One such innovation is the lace door frame roll forming machine, a pivotal piece of equipment in the production of high-quality door frames. This article explores the significance, functionality, and benefits of lace door frame roll forming machines in the contemporary manufacturing landscape.

Understanding Roll Forming Technology

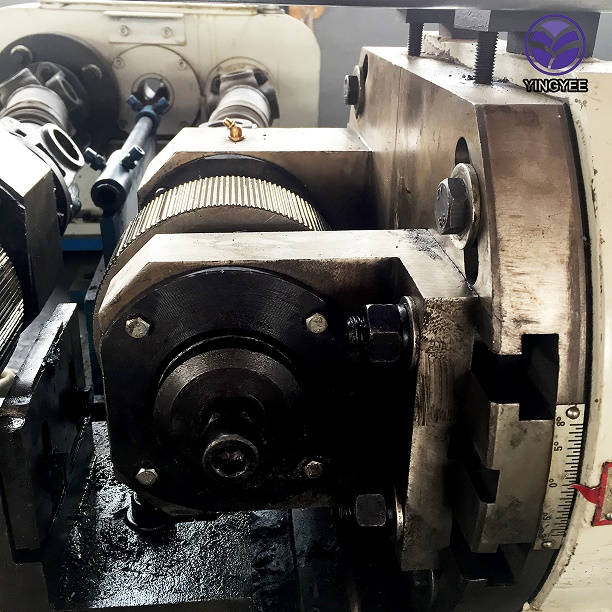

Roll forming is a continuous bending process in which a long strip of metal, usually coiled steel, is passed through a series of rollers to create a specific profile. The process is highly efficient, capable of producing complex shapes with precision and consistency. The lace door frame roll forming machine harnesses this technology, enabling manufacturers to produce intricate door frame designs that are both aesthetically pleasing and structurally sound.

The Significance of Lace Door Frames

Lace door frames have gained popularity for their elegant and intricate designs, often used in residential and commercial buildings to add a touch of sophistication. These frames not only enhance the exterior appeal of doors but also provide strength and durability, making them an ideal choice for various architectural applications. The demand for lace door frames has surged, leading to a greater need for efficient production methods that the roll forming process can fulfill.

Features of Lace Door Frame Roll Forming Machines

Modern lace door frame roll forming machines come equipped with several advanced features tailored to enhance their performance

1. Precision Engineering These machines are designed with precision in mind, ensuring that every component of the door frame meets exact specifications. The accuracy of the roll forming process allows for tight tolerances, which is critical in maintaining the quality and structural integrity of the final product.

2. Customizable Designs One of the standout benefits of these machines is their ability to create customized profiles. Manufacturers can design unique lace patterns to meet specific customer preferences or architectural requirements, providing a competitive edge in the market.

3. High Production Efficiency Lace door frame roll forming machines are capable of operating at high speeds, significantly boosting production rates without compromising on quality. This efficiency helps manufacturers meet increasing demand while reducing operational costs.

4. Versatile Materials These machines can work with various materials, including mild steel, galvanized steel, and aluminum, allowing manufacturers to choose the best material for their applications. This versatility ensures that the door frames produced are suitable for different environments and conditions.

5. Automated Systems Many modern machines feature automated systems that minimize manual intervention, thereby reducing the risk of errors and enhancing safety. Automated control systems can monitor the production process in real-time, ensuring consistent quality throughout the manufacturing run.

The Environmental Impact

As sustainability becomes an increasingly important consideration in manufacturing, lace door frame roll forming machines are designed with eco-friendly practices in mind. By optimizing material usage and reducing waste, these machines contribute to more sustainable manufacturing processes. Furthermore, the ability to produce lightweight yet strong frames means reduced energy consumption during transportation and installation.

Conclusion

The lace door frame roll forming machine represents a significant advancement in the manufacturing sector, combining technological prowess with design innovation. As the demand for custom-designed, high-quality door frames continues to rise, these machines will play a crucial role in meeting the needs of modern architecture and construction. By embracing this technology, manufacturers can enhance their production capabilities, reduce costs, and offer customers a product that blends durability with aesthetic appeal. In a rapidly evolving landscape, the lace door frame roll forming machine stands out as a quintessential tool for manufacturers aiming to thrive in this competitive market.