The Advantages of Lace Door Frame Roll Forming Machines

In the realm of modern manufacturing, the efficiency and precision of production machinery have become paramount. One such innovative machine is the lace door frame roll forming machine, which plays a crucial role in the construction of durable and aesthetically pleasing door frames. This article delves into the advantages of using lace door frame roll forming machines in the production process.

Firstly, the primary benefit of lace door frame roll forming machines is their ability to produce high volumes of door frames with remarkable consistency. These machines utilize a continuous forming process where flat metal sheets are gradually shaped into the desired profile. As a result, manufacturers can achieve uniformity across productions with minimal variations. This consistency not only enhances the marketability of the products but also meets the stringent quality standards required in the construction industry.

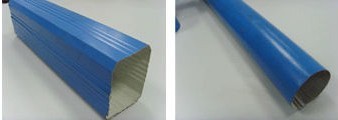

Moreover, the lace design of these door frames offers both aesthetic appeal and functional benefits. Lace patterns can provide an elegant touch to door frames, enhancing the overall visual appeal of a property. Additionally, the intricate designs often improve structural integrity, making the frames not only beautiful but also more robust. This dual functionality positions lace door frames as an attractive option for builders and homeowners alike.

Another significant advantage is the efficiency of the roll forming process. The automatic operation of lace door frame roll forming machines significantly reduces labor costs and production times. Once set up, these machines can run continuously, with minimal operator intervention required, thus streamlining the manufacturing process. This efficiency translates to lower production costs, allowing manufacturers to offer competitive pricing in the marketplace.

In terms of material utilization, lace door frame roll forming machines are designed to minimize waste. The precision engineering of these machines ensures that raw materials are utilized effectively, reducing scrap rates and contributing to a more sustainable production process. This environmental consideration is increasingly important in today's manufacturing landscape, as companies strive to adopt greener practices.

Furthermore, the adaptability of lace door frame roll forming machines is worth mentioning. These machines can be customized to produce various designs and specifications, making them versatile tools in the manufacturing sector. Companies can easily switch between different frame designs without significant downtime, allowing for greater flexibility in response to market demands.

Lastly, the durability of the products made using lace door frame roll forming machines cannot be overlooked. The use of high-quality materials combined with the precision of the forming process results in door frames that are strong and long-lasting. This durability not only satisfies the consumers’ expectations but also enhances the reputation of manufacturers in the industry.

In conclusion, lace door frame roll forming machines present numerous advantages, including efficiency, consistency, aesthetic appeal, and adaptability. As the demand for high-quality door frames continues to rise, investing in advanced machinery like lace door frame roll forming machines proves to be a strategic decision for manufacturers seeking to excel in the competitive construction market.