Exploring the Benefits of Keel Roll Forming Machines

Keel roll forming machines have become integral in the production of high-quality structural components used in various industries, including construction, automotive, and manufacturing. These machines are specifically designed to produce steel or metal keels, which serve as the fundamental framework for many structural applications. Understanding the functionality and advantages of keel roll forming machines can provide insights into their significance in modern industrial processes.

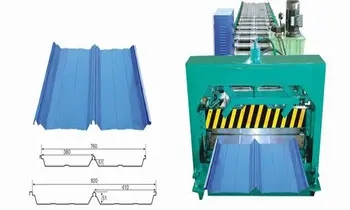

At its core, a keel roll forming machine operates through a continuous process where flat metal strips are fed into a series of rollers. These rollers gradually shape the metal strip into the desired profile, forming the keel shape. The precise engineering of these machines allows for high-speed production with minimal waste, making them an efficient choice for manufacturers. The versatility of keel roll forming machines allows them to produce various keel sizes and shapes, catering to specific industry needs.

One of the primary benefits of keel roll forming machines is their ability to enhance productivity. With continuous operation and automated processes, manufacturers can achieve high outputs in a short amount of time. This increased efficiency not only meets market demands but also reduces labor costs, contributing to overall cost savings in production.

Additionally, the quality of products made using keel roll forming machines is consistently high. The automation and precision involved in the roll forming process minimize the chance for human error, resulting in uniform and accurately shaped components. This level of consistency is essential, especially in industries where structural integrity is crucial, such as construction and automotive manufacturing.

Another significant advantage is the flexibility of design. Keel roll forming machines can easily adapt to produce different sizes and profiles by changing the roll design and settings. This adaptability enables manufacturers to respond swiftly to market demands and customize products according to client specifications without the need for extensive retooling.

Moreover, keel roll forming machines are environmentally friendly. The roll forming process generates less scrap metal compared to traditional machining methods, making it a more sustainable option. As industries increasingly focus on sustainable practices, the demand for such efficient machinery grows.

In conclusion, keel roll forming machines play a vital role in producing durable and precise structural components. Their efficiency, high product quality, design flexibility, and environmental benefits make them an attractive choice for manufacturers. As technology advances, these machines are expected to evolve further, continuing to shape the future of industrial production.