In the world of electrical installations, having high-quality junction boxes is critical to ensuring safety, reliability, and durability. The demand for electrical metal junction boxes has risen as industries continue to grow and require efficient solutions for housing electrical components. Whether you are exploring an electrical metal junction box making machine, researching junction box making machines, or evaluating electrical metal box making machine prices, this advertorial will guide you through the essential factors to consider when purchasing these machines. The right equipment will not only streamline your production process but also ensure that you can meet the increasing demand for high-quality electrical junction boxes.

An electrical metal junction box making machine is designed to manufacture strong, reliable, and durable junction boxes from metal materials. These boxes are essential in protecting electrical components and wiring from environmental factors, moisture, and mechanical damage. The electrical metal junction box making machine can efficiently produce boxes in various sizes and shapes, meeting the specific needs of different electrical applications, from residential to industrial settings.

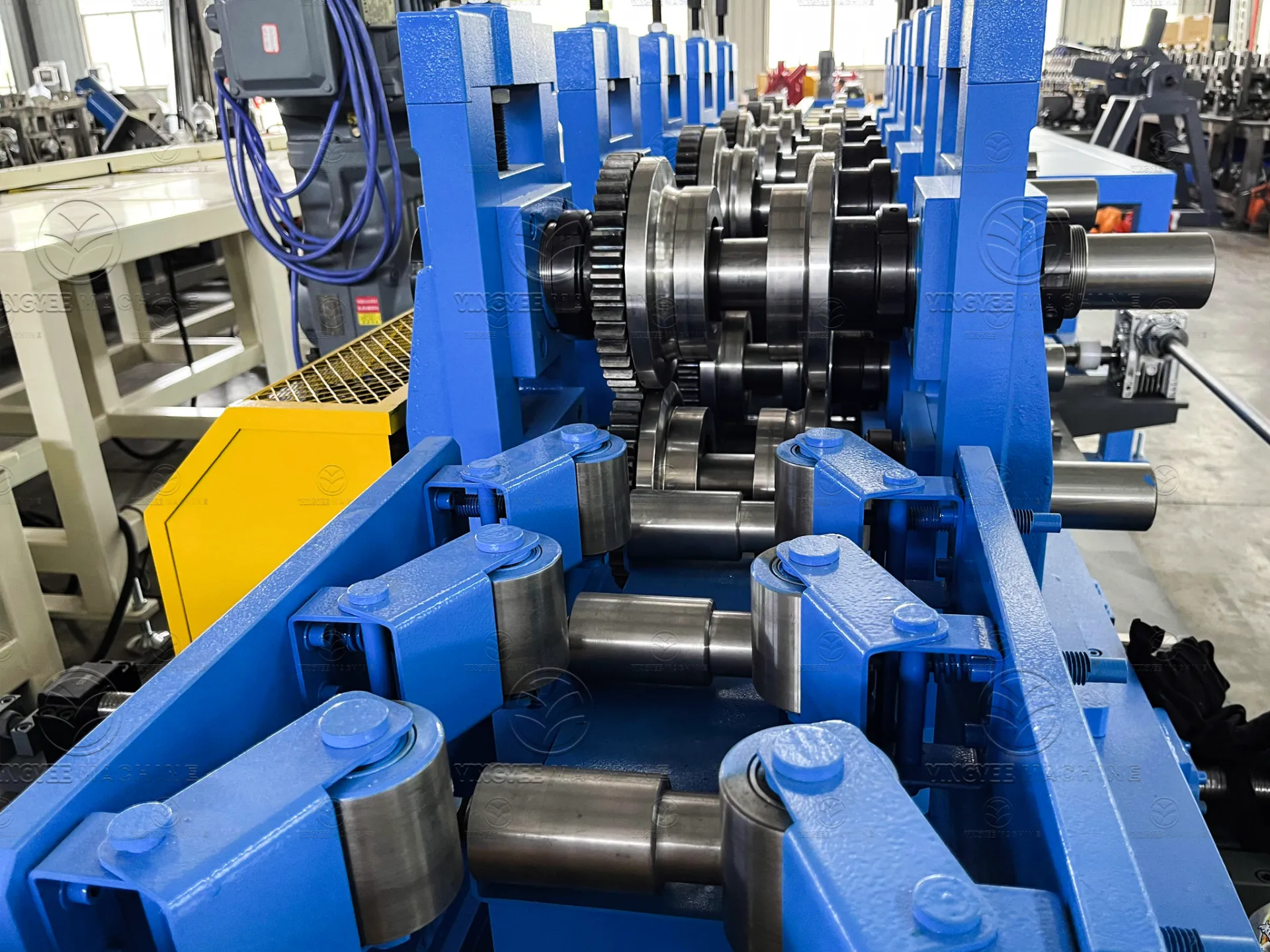

These machines operate by feeding metal sheets into a series of rollers and forming stations, where they are cut, shaped, and bent to the required specifications. The result is a precision-made junction box that is ready for assembly and use in electrical installations. The electrical metal junction box making machine offers high productivity, precision, and consistency, which are crucial for manufacturers looking to meet the growing demand for electrical junction boxes. With automation and advanced controls, these machines can also reduce manual labor and increase production speed, helping businesses meet tight deadlines.

A junction box making machine is an essential investment for manufacturers in the electrical industry. These machines are designed to create junction boxes that provide protection and organization for electrical wiring. Junction boxes are critical for ensuring electrical systems are safe and compliant with building codes and regulations. With a junction box making machine, manufacturers can produce high-quality boxes that protect wiring and connections in homes, factories, and commercial buildings.

The junction box making machine typically operates by cutting and forming metal sheets into the appropriate dimensions and shapes. Advanced machines offer the ability to produce boxes with different features, such as mounting holes, knockouts, and internal dividers for organized wiring. By investing in a high-quality junction box making machine, businesses can increase production efficiency, reduce material waste, and ensure consistent quality. These machines offer flexibility and versatility, enabling manufacturers to produce a wide variety of box designs that meet specific customer needs.

When considering the purchase of an electrical metal box making machine, understanding the electrical metal box making machine price is essential. The price of these machines can vary depending on factors such as their features, production capacity, and the complexity of the equipment. Generally, machines with advanced automation, higher production speeds, and more versatile design capabilities will come with a higher price tag. However, it’s important to weigh the long-term benefits of the machine, including improved efficiency and reduced labor costs, to determine the overall value of the investment.

The electrical metal box making machine price can also be influenced by the manufacturer’s reputation, the quality of materials used, and the machine’s maintenance requirements. Higher-end machines typically offer better precision, durability, and faster cycle times, which can significantly reduce production costs in the long run. When evaluating electrical metal box making machine prices, it’s crucial to consider not just the upfront cost, but also the long-term operational savings and productivity gains that can result from investing in a higher-quality machine.

Choosing an electrical metal box making machine offers several advantages for manufacturers in the electrical industry. These machines are specifically designed to provide the highest levels of precision and quality, ensuring that the junction boxes produced are reliable and durable. Electrical metal boxes play a crucial role in protecting electrical components, preventing electrical hazards, and ensuring safe operation. A well-built electrical metal box making machine guarantees that each box is made to the exact specifications required for optimal performance.

By investing in a high-quality electrical metal box making machine, manufacturers can increase production capacity, reduce material waste, and maintain consistent product quality. These machines are equipped with automation features that allow for faster production times and higher output, which is crucial for meeting the growing demand for electrical boxes in various industries. Additionally, an efficient electrical metal box making machine reduces labor costs, as many tasks that would normally require manual labor are automated, improving overall production efficiency and profitability.

The efficiency of a junction box making machine is essential for manufacturers who need to produce high volumes of junction boxes in a timely and cost-effective manner. With the right junction box making machine, businesses can achieve high-speed production without compromising on quality. These machines are designed to handle various types of metals, such as steel, aluminum, and galvanized sheet metal, ensuring that manufacturers can meet the needs of different projects and industries.

A key advantage of investing in a junction box making machine is the ability to minimize manual labor and reduce the risk of human error. Automation features such as automatic feeding, cutting, and bending allow for smooth and continuous operation, maximizing production output. The junction box making machine can also be programmed to produce boxes with different sizes, shapes, and features, providing flexibility and customization options for manufacturers. By maximizing production efficiency, businesses can meet customer demands faster, improve profitability, and reduce overall manufacturing costs.

In conclusion, whether you're considering an electrical metal junction box making machine, researching junction box making machines, or evaluating the electrical metal box making machine price, investing in high-quality equipment is essential for producing reliable and durable electrical junction boxes. The right machines will improve production efficiency, reduce costs, and ensure that your products meet industry standards. By understanding the key factors to consider when purchasing these machines, you can make an informed decision that will benefit your business in the long term.