Understanding the IBR Roll Forming Machine Innovations and Applications

The IBR roll forming machine is a sophisticated piece of equipment designed to produce IBR (Inverted Box Rib) sheets, widely used in the construction and roofing industries. This technology combines engineering precision with automation, allowing for efficient production of high-quality roofing panels. With the growing demand for durable and aesthetically pleasing roofing solutions, the popularity of IBR sheets has surged, making the IBR roll forming machine a pivotal asset for manufacturers.

What is an IBR Roll Forming Machine?

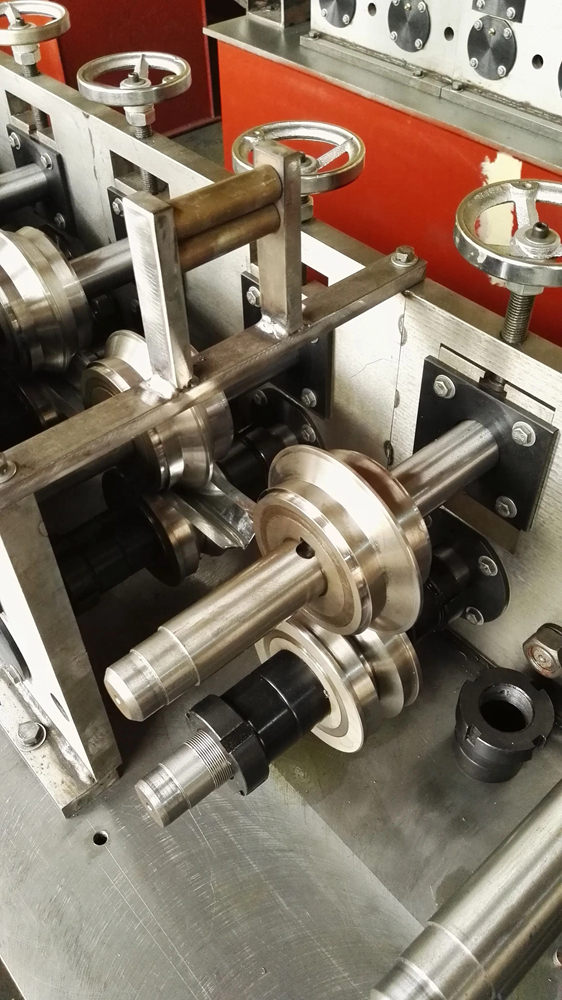

An IBR roll forming machine is a specialized machine that processes metal coils into IBR profiles through a series of rollers. These machines utilize cold forming technology, whereby the metal is shaped at room temperature, resulting in a strong and resilient final product. Typically made from high-tensile steel or galvanized metal, the IBR sheets produced are known for their strength, lightweight properties, and resistance to environmental factors.

The roll forming process begins with feeding a flat metal strip into the machine, which then passes through a series of rollers that gradually shape the metal into the desired IBR profile. The entire process is automated, ensuring consistency and precision. Furthermore, advanced IBR roll forming machines can be equipped with features like automatic cutting systems, which allow for on-demand production, reducing material waste and enhancing operational efficiency.

Key Features and Benefits

1. Durability and Strength IBR roofing sheets are designed to withstand harsh weather conditions, making them a favored choice for industrial and residential buildings alike. The robustness of the material ensures long-lasting performance.

2. Versatility The IBR roll forming machine isn't limited to producing only one type of profile. With minor adjustments, these machines can produce a variety of profiles, catering to different customer preferences and building requirements.

3. Efficiency and Speed Modern IBR roll forming machines are engineered for high-speed production. This capability allows manufacturers to meet large-scale demands without sacrificing quality.

4. Cost-Effectiveness By optimizing material usage and reducing labor costs through automation, the cost of producing IBR sheets is significantly lower compared to traditional manufacturing processes.

5. Aesthetics The finished IBR sheets have a modern appearance, enhancing the aesthetic appeal of buildings. Available in various colors and finishes, they can be tailored to meet specific design preferences.

Application in Construction

IBR sheets have a vast array of applications in the construction industry. They are commonly used for roofing and cladding in commercial buildings, warehouses, and residential projects. Their lightweight nature reduces the load on supporting structures, making them an efficient choice for builders. Additionally, the interlocking design of IBR panels ensures that water drainage is optimized, reducing the risk of leaks and water damage.

The eco-friendly aspect of using IBR sheets cannot be overlooked. Many manufacturers produce these sheets from recycled materials, contributing to sustainability efforts in construction. Furthermore, their reflective finishes can reduce heat absorption, contributing to energy efficiency in buildings.

Conclusion

The IBR roll forming machine stands at the forefront of modern roofing solutions, combining technology and innovation to meet the demands of a dynamic construction market. As the trend towards sustainable and high-performance building materials continues to grow, the role of IBR sheets and the machines that produce them will only become more significant. Investing in an IBR roll forming machine is not just a strategic business move; it is a commitment to quality, efficiency, and sustainability in the construction industry.