Main Furring Roll Forming Machine An Overview

In the realm of structural engineering and construction, the demand for efficiency and precision has never been more critical. Among the tools that have revolutionized the industry is the main furring roll forming machine. This sophisticated piece of machinery is designed to produce metal furring strips, which are essential for various construction applications, including wall framing and ceiling installations.

What is a Furring Strip?

Furring strips, often made from materials such as steel or aluminum, are narrow strips used to create a level surface onto which other materials can be attached. They play a fundamental role in the construction of walls and ceilings by providing a space where insulation can be installed, and by ensuring straight and level surfaces for drywall or other finishing materials.

The Role of Roll Forming Machines

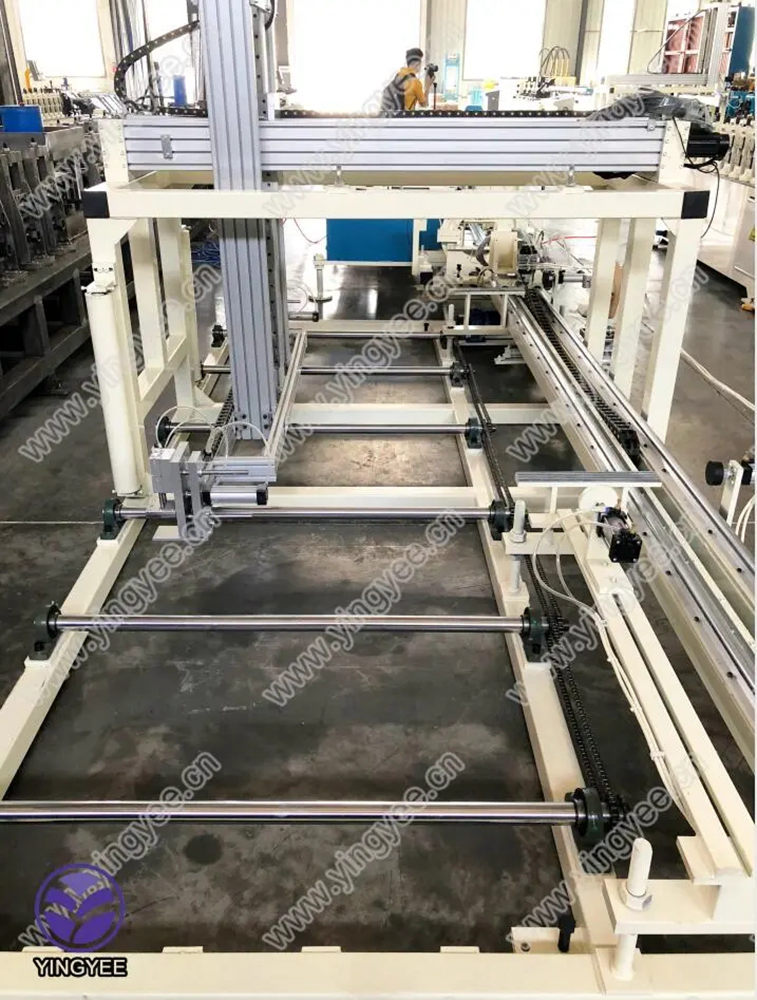

Roll forming machines are integral in the production of furring strips. They operate by continuously feeding a strip of metal through a series of rollers, which gradually shape the metal into the desired contour. The process is highly efficient, allowing for the rapid production of long lengths of furring strips with consistent dimensions and minimal waste.

Features of Main Furring Roll Forming Machines

1. Versatility One of the primary benefits of furring roll forming machines is their versatility. They can be adjusted to produce various profiles of furring strips, accommodating different project specifications and design requirements.

2. High Precision Advanced roll forming machines come equipped with computer numerical control (CNC) technology, ensuring that each strip produced meets exact specifications. This precision reduces the need for manual adjustments and enhances the overall quality of the finished product.

3. Speed and Efficiency The roll forming process is significantly faster than traditional methods of strip production. Machines can operate at high speeds, allowing manufacturers to meet tight deadlines without compromising on quality.

4. Durability Furring strips produced by roll forming machines are not only lightweight but also strong and durable. The process allows for the use of high-quality steel, which can withstand the rigors of construction environments.

5. Minimal Waste The roll forming process is inherently efficient in terms of material usage. By utilizing continuous lengths of metal, the amount of waste generated during production is minimized. This sustainability aspect is increasingly important in today’s eco-conscious market.

Applications of Furring Strips

The applications for furring strips are vast. They are commonly used in residential and commercial buildings for the installation of drywall and other materials. Furring strips create the necessary space for insulation, which improves energy efficiency and occupant comfort. Additionally, they are used in the installation of ceilings, particularly in areas where drop ceilings are required.

Conclusion

The main furring roll forming machine is a pivotal development in the construction industry, enabling the mass production of essential components with speed, precision, and efficiency. As the demand for construction projects continues to grow, the importance of such machinery cannot be overstated. From providing structural integrity to enhancing energy efficiency, the impact of furring strips—produced by advanced roll forming technology—will continue to be felt in construction for years to come. Overall, the roll forming process represents not just a technological advancement but also a step toward more sustainable and efficient building practices in the industry.