The Ridge Cap Tile Roll Forming Machine An Essential Tool for Modern Roofing Solutions

In the ever-evolving construction industry, efficient and durable roofing solutions are paramount. Among the various innovations that facilitate the production of such roofing materials, the Ridge Cap Tile Roll Forming Machine stands out as a vital tool for manufacturers and builders alike. This machine not only enhances the aesthetic appeal of roofs but also significantly improves their structural integrity and longevity.

Overview of Ridge Cap Tiles

Ridge cap tiles are essential roofing components designed to seal the ridges where two roof slopes meet. They play a critical role in preventing water infiltration, thus protecting the underlying structures. Typically, ridge cap tiles are made from various materials, including clay, concrete, and metal, each offering unique advantages concerning durability, weight, and cost. As demand for stylish and effective roofing solutions grows, so does the need for efficient production methodologies, which is where the ridge cap tile roll forming machine comes into play.

Functionality of the Machine

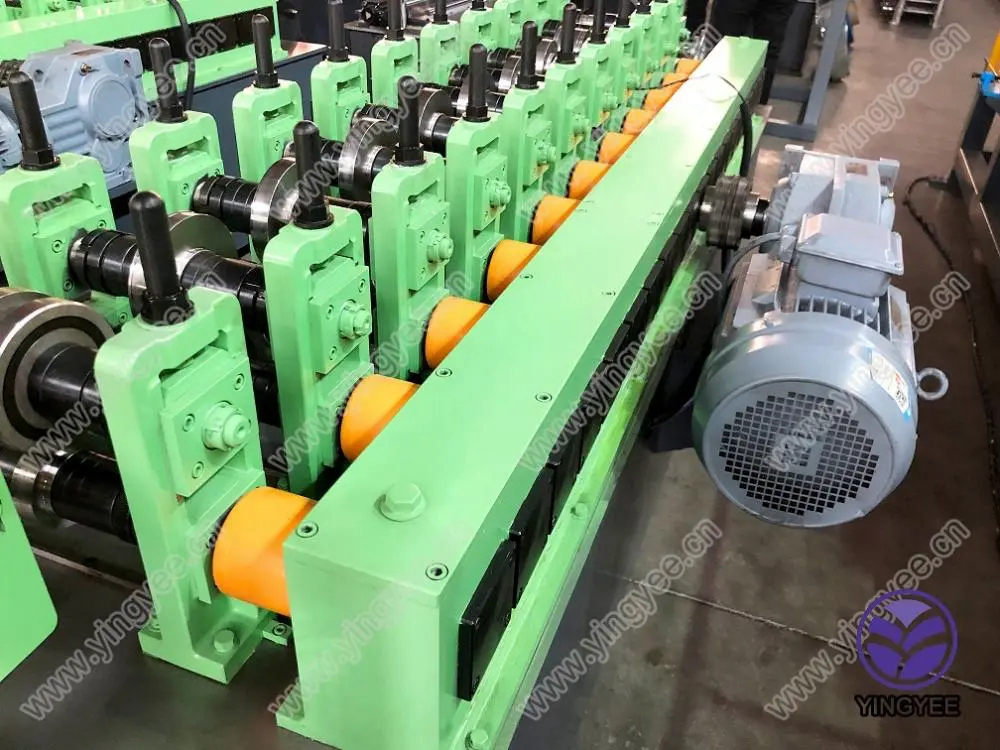

The ridge cap tile roll forming machine operates through a continuous production process. It involves feeding metal coils into the machine, which then gradually shapes the metal through a series of rollers and dies. This automated process allows for high-speed production while maintaining precision, ensuring that each tile produced meets strict quality and dimensional requirements.

The machine is designed to handle various materials, including galvanized steel, stainless steel, and aluminum. By incorporating advanced technology such as Computer Numerical Control (CNC), manufacturers can easily adjust settings for producing different tile profiles or sizes. This versatility is a significant advantage in today’s competitive market, where client specifications can vary drastically.

Benefits of Using a Ridge Cap Tile Roll Forming Machine

1. Efficiency and Speed Traditional manufacturing methods for ridge cap tiles can be slow and labor-intensive. The roll forming machine streamlines production, enabling manufacturers to produce a high volume of tiles in a shorter timeframe.

2. Cost-Effectiveness By reducing labor costs and waste material, the machine enhances overall production efficiency. The continuous nature of the roll forming process means fewer operational interruptions, leading to more cost-effective manufacturing.

3. Customization The capability to easily modify tile designs and sizes empowers manufacturers to respond quickly to market trends and customer requests. This flexibility is crucial in an industry where personalization is increasingly becoming the norm.

4. Quality Control Roll forming ensures that every tile produced is uniform in quality and thickness. This consistency is vital in the roofing industry, where the reliability of materials directly affects the safety and durability of structures.

5. Durability and Strength The ridge cap tiles produced by this machine are not only aesthetically pleasing but also designed to withstand harsh weather conditions. The precision of the roll forming process enhances the tiles' strength, making them a long-lasting investment for any roofing project.

Conclusion

The ridge cap tile roll forming machine is revolutionizing the way roofing materials are manufactured. By combining efficiency, customization, and quality, it offers an innovative solution to an age-old problem in construction – how to provide durable and effective roofing without sacrificing style or functionality. As the demand for reliable roofing materials continues to rise, so too will the significance of advanced machinery like the ridge cap tile roll forming machine, paving the way for a new era in roofing technology.