The Significance of Pipe Roll Forming Machines in Modern Manufacturing

In today's industrial landscape, efficient production processes are paramount, and one of the key players in achieving this efficiency is the pipe roll forming machine. This advanced piece of equipment is designed to transform flat metal strips into various shapes, forming pipes and other cylindrical components with remarkable precision and speed. The significance of pipe roll forming machines has grown substantially as industries increasingly prioritize automation and consistency in their manufacturing operations.

How Pipe Roll Forming Machines Work

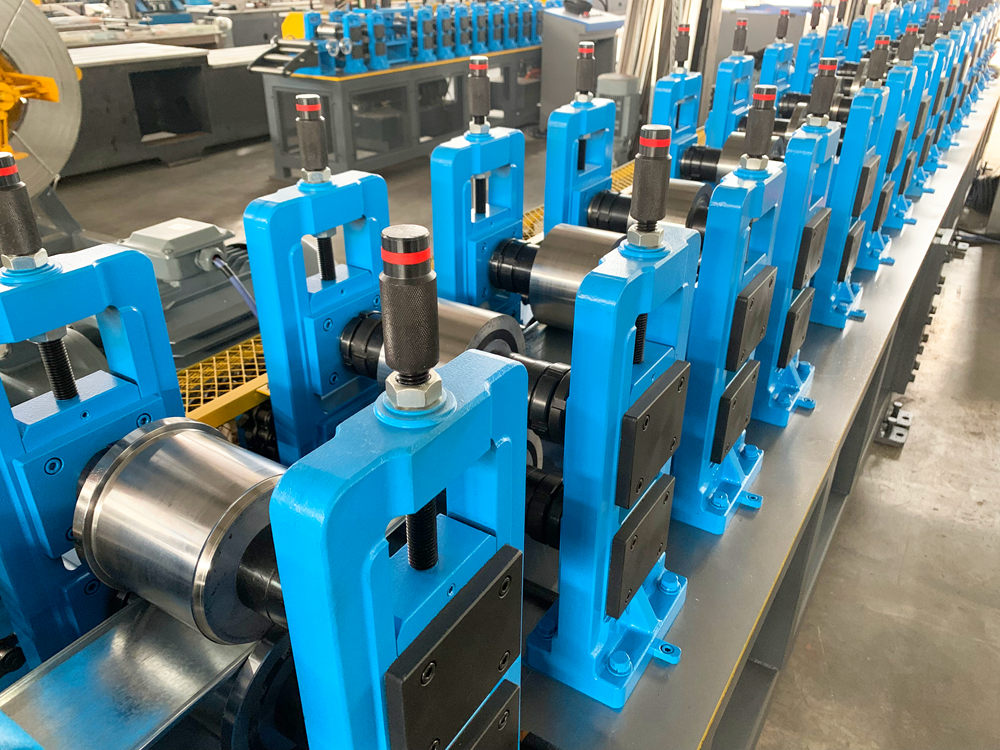

At its core, a pipe roll forming machine operates on the principle of continuous rolled forming. The process begins with feeding a flat metal strip, often made of steel, aluminum, or other alloys, through a series of rollers that progressively bend and shape the material into the desired pipe configuration. These machines can create pipes of varying diameters and wall thicknesses, making them versatile for multiple applications.

The roll forming process involves several key stages, including feeding, forming, welding, and cutting. As the metal strip passes through the rollers, it is gradually shaped into a round or square pipe. For welded pipes, high-frequency welding is typically employed to bond the edges of the metal strip together, ensuring structural integrity. Once the pipe has reached the desired length, it is cut to specification, allowing for immediate use in various applications.

Advantages of Using Pipe Roll Forming Machines

One of the primary advantages of using pipe roll forming machines is their efficiency. The continuous formation process allows for high-speed production, significantly reducing lead times compared to traditional manufacturing methods. This efficiency translates to lower labor costs and increased output, enabling manufacturers to meet rising demand without sacrificing quality.

Moreover, pipe roll forming machines are known for their precision

. The use of computer-controlled systems ensures that each piece produced meets stringent tolerances, minimizing waste and the need for rework. This level of precision is particularly crucial in industries such as construction and automotive, where component integrity is non-negotiable.Another significant advantage is the versatility of pipe roll forming machines. These machines can be designed to produce a wide range of pipe sizes and shapes, catering to the specific needs of different industries. Additionally, they can be adjusted quickly to accommodate changes in production requirements, making them a valuable asset for manufacturers looking to adapt to market fluctuations.

Applications Across Industries

The applications of pipe roll forming machines are extensive. In the construction industry, they are used to create structural components, scaffolding systems, and railings. In the automotive sector, these machines produce exhaust pipes, chassis components, and various support structures. Additionally, the oil and gas industry relies on roll-formed pipes for transportation and structural applications due to their strength and durability.

As the demand for sustainable practices continues to rise, pipe roll forming machines can also contribute to eco-friendly manufacturing processes. By minimizing waste and allowing for the use of recycled materials, these machines align with the growing emphasis on sustainability in manufacturing.

Conclusion

In conclusion, the pipe roll forming machine is a vital tool in modern manufacturing, offering efficiency, precision, and versatility. As industries evolve and demand for high-quality, cost-effective solutions increases, the importance of these machines will only continue to rise. Embracing technology and innovation in the manufacturing process is essential for businesses aiming to remain competitive in an ever-changing market. The advancements in pipe roll forming technology will undoubtedly play a significant role in shaping the future of manufacturing across various sectors.